Why does my up-pipe keep cracking???

#1

Hi guys and girls.

A few years ago I fitted a good quality stainless up-pipe (I'm not going to name and shame the maker at the moment). It's a well made bit of kit from a wel known maker and not a cheapo ebay job.

The car is a MY00 UK Turbo with the following engine mods:

Full decat stainless system.

Light weight engine pulleys and flywheel.

Walbro fuel pump

Sard FPR

Green cotton air filter

Remap to 271bhp at Scooby Clinic.

It drives perfect and has done since the work was done in 2008.

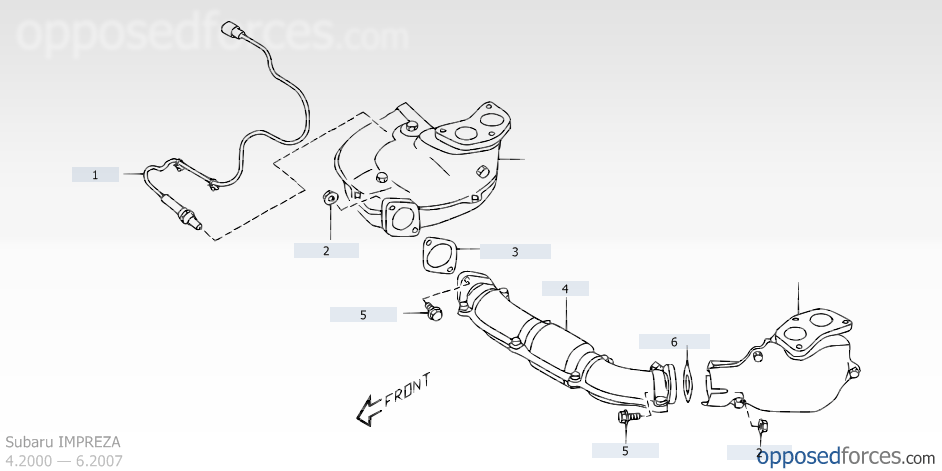

After about three years I noticed that the up-pipe had a crack around the join where it meets the turbo. Here are the pics:

So I complained and got a replacement (lifetime guarantee job).

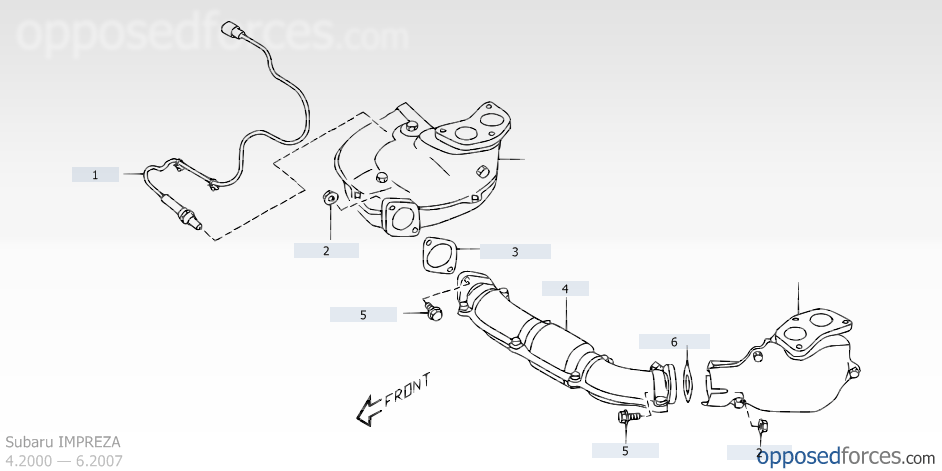

Now a year later I find this:

Even worse and less time!

Why does this keep happening? It was hard getting it replaced the first time and I am sure they will argue this time and say its my car or the fitting whatever.... The first one was fitted by Scooby Clinic and I did the second and I can't see how it can be fitted wrong! My car is not madly tuned.

I currently have a cheapo flex japspeed one on the car until I work out why I am breaking the expensive ones.

Hopefully I will get another replacement but I don't want yet another breakage. The pipe has a slip joint and you would have thought that this would stop stress and cracking...

A few years ago I fitted a good quality stainless up-pipe (I'm not going to name and shame the maker at the moment). It's a well made bit of kit from a wel known maker and not a cheapo ebay job.

The car is a MY00 UK Turbo with the following engine mods:

Full decat stainless system.

Light weight engine pulleys and flywheel.

Walbro fuel pump

Sard FPR

Green cotton air filter

Remap to 271bhp at Scooby Clinic.

It drives perfect and has done since the work was done in 2008.

After about three years I noticed that the up-pipe had a crack around the join where it meets the turbo. Here are the pics:

So I complained and got a replacement (lifetime guarantee job).

Now a year later I find this:

Even worse and less time!

Why does this keep happening? It was hard getting it replaced the first time and I am sure they will argue this time and say its my car or the fitting whatever.... The first one was fitted by Scooby Clinic and I did the second and I can't see how it can be fitted wrong! My car is not madly tuned.

I currently have a cheapo flex japspeed one on the car until I work out why I am breaking the expensive ones.

Hopefully I will get another replacement but I don't want yet another breakage. The pipe has a slip joint and you would have thought that this would stop stress and cracking...

#3

Scooby Regular

Join Date: Nov 2013

Location: Birmingham

Posts: 119

Likes: 0

Received 0 Likes

on

0 Posts

the first picture looks like it has corroded around the weld (wrong type of weld?), the second though, that looks like its actually corroded through and that has caused the crack. Certainly the appearance of the second, younger pipe looks like jot is made from a much lower grade of steel.

#4

Scooby Regular

I take it, it had been heat wrapped??

Does the car still have it's undertray??

Does the car still have it's undertray??

#5

Both are the same pipe from the same manufacturer.

The second one was lightly wrapped the first one was not.

Turbo still works fine. Obviously dropped a bit of boost while running with the crack but back to normal with a new pipe fitted.

Yep I still have the under tray as corrosion drives me nuts and I do everything I can to stop it.

Any idea on how to stop it happening again? I can not wrap it but this increases engine bay temps... I could ceramic coat but If I do this surely it will make the pipe hotter leading to more stress and if it breaks then the quite considerable money spend on the coat will be wasted.

I want to fit and RCM stainless manifold too and have that coated but to be honest all these upgraded parts seem to be more prone to failure then OE bits. The original up-pipe looked **** and was heavy but it worked. As do the OE headers... Upgraded parts that fail are one of my pet hates.

I haven't heard of many other people having this happen and wondered if anything specific to my car could cause it?

The second one was lightly wrapped the first one was not.

Turbo still works fine. Obviously dropped a bit of boost while running with the crack but back to normal with a new pipe fitted.

Yep I still have the under tray as corrosion drives me nuts and I do everything I can to stop it.

Any idea on how to stop it happening again? I can not wrap it but this increases engine bay temps... I could ceramic coat but If I do this surely it will make the pipe hotter leading to more stress and if it breaks then the quite considerable money spend on the coat will be wasted.

I want to fit and RCM stainless manifold too and have that coated but to be honest all these upgraded parts seem to be more prone to failure then OE bits. The original up-pipe looked **** and was heavy but it worked. As do the OE headers... Upgraded parts that fail are one of my pet hates.

I haven't heard of many other people having this happen and wondered if anything specific to my car could cause it?

Last edited by FMJ; 25 November 2013 at 11:38 PM.

#7

Scooby Regular

iTrader: (7)

Hi there

Are you using support bracket for Up pipe and turbo?

Are you using ALS or LC?

I would for sue invest in yours case to the EGT gauge with the EGT sensor

About the wrapping Up pipe,we are used previously GT Spec headers with LC/ALS and this never happen to us

I would suspect something causing to crack and would wrap at least the headers and up pipe, wrapping up pipe will not cause raising under bonnet temps,I would say would decrease the temps under bonnet

Jura

Are you using support bracket for Up pipe and turbo?

Are you using ALS or LC?

I would for sue invest in yours case to the EGT gauge with the EGT sensor

About the wrapping Up pipe,we are used previously GT Spec headers with LC/ALS and this never happen to us

I would suspect something causing to crack and would wrap at least the headers and up pipe, wrapping up pipe will not cause raising under bonnet temps,I would say would decrease the temps under bonnet

Jura

Trending Topics

#8

Scooby Regular

Join Date: May 2013

Location: welling,kent

Posts: 1,103

Likes: 0

Received 0 Likes

on

0 Posts

Both are the same pipe from the same manufacturer.

The second one was lightly wrapped the first one was not.

Turbo still works fine. Obviously dropped a bit of boost while running with the crack but back to normal with a new pipe fitted.

Yep I still have the under tray as corrosion drives me nuts and I do everything I can to stop it.

Any idea on how to stop it happening again? I can not wrap it but this increases engine bay temps... I could ceramic coat but If I do this surely it will make the pipe hotter leading to more stress and if it breaks then the quite considerable money spend on the coat will be wasted.

I want to fit and RCM stainless manifold too and have that coated but to be honest all these upgraded parts seem to be more prone to failure then OE bits. The original up-pipe looked **** and was heavy but it worked. As do the OE headers... Upgraded parts that fail are one of my pet hates.

I haven't heard of many other people having this happen and wondered if anything specific to my car could cause it?

The second one was lightly wrapped the first one was not.

Turbo still works fine. Obviously dropped a bit of boost while running with the crack but back to normal with a new pipe fitted.

Yep I still have the under tray as corrosion drives me nuts and I do everything I can to stop it.

Any idea on how to stop it happening again? I can not wrap it but this increases engine bay temps... I could ceramic coat but If I do this surely it will make the pipe hotter leading to more stress and if it breaks then the quite considerable money spend on the coat will be wasted.

I want to fit and RCM stainless manifold too and have that coated but to be honest all these upgraded parts seem to be more prone to failure then OE bits. The original up-pipe looked **** and was heavy but it worked. As do the OE headers... Upgraded parts that fail are one of my pet hates.

I haven't heard of many other people having this happen and wondered if anything specific to my car could cause it?

#11

Scooby Regular

Your first pictures show a bolt head which would suggest the failure is at the manifold end...........

The later ones are clearly the turbo end.

First failure looks to be a stress crack and could be due to not using a thick enough gasket to take up any misalignment in the flanges - a known problem with/for leaks etc in this area.

The second failure looks to be corrosion as well as stress related hence the questions on wrapping and undertray. (wrap remaining wet - speeding up corrosion process)

As others have already said, any missing brackets for the turbo/downpipe will be a good place to start.

OEM manifold or aftermarket??

Always a good idea to slacken off manifold to manifold section bolts and manifold to head nuts when fitting to assist in proper alignment.

The later ones are clearly the turbo end.

First failure looks to be a stress crack and could be due to not using a thick enough gasket to take up any misalignment in the flanges - a known problem with/for leaks etc in this area.

The second failure looks to be corrosion as well as stress related hence the questions on wrapping and undertray. (wrap remaining wet - speeding up corrosion process)

As others have already said, any missing brackets for the turbo/downpipe will be a good place to start.

OEM manifold or aftermarket??

Always a good idea to slacken off manifold to manifold section bolts and manifold to head nuts when fitting to assist in proper alignment.

#12

Scooby Regular

iTrader: (1)

Are the cracks are happening at exactly the same place (splitting occuring at the same side)?

If so this may indicate either some out of alignment issue (uppipe manufacture or turbo etc) or poss engine mounts....???

If the splits are on different sides of the same joint etc, you might just be unlucky...?

If so this may indicate either some out of alignment issue (uppipe manufacture or turbo etc) or poss engine mounts....???

If the splits are on different sides of the same joint etc, you might just be unlucky...?

#13

Scooby Regular

Join Date: May 2013

Location: welling,kent

Posts: 1,103

Likes: 0

Received 0 Likes

on

0 Posts

Are the cracks are happening at exactly the same place (splitting occuring at the same side)?

If so this may indicate either some out of alignment issue (uppipe manufacture or turbo etc) or poss engine mounts....???

If the splits are on different sides of the same joint etc, you might just be unlucky...?

If so this may indicate either some out of alignment issue (uppipe manufacture or turbo etc) or poss engine mounts....???

If the splits are on different sides of the same joint etc, you might just be unlucky...?

#14

Scooby Regular

Engine and exhaust as far back as the "donut" joint should move as one, (unless brackets are missing) so doubt engine mounts are the problem.

#17

Wow lots of replies thanks guys and lots of things to look into.

To try and answer all the questions:

The first up-pipe was not wrapped it was left as it came with no heat shields or wrap. It was fitted with the OE manifold which still had its heat shields in place. It was fitted with a haywood and scott downpipe which has the bracket.

All OE brackets and mounts are present and tight.

The engine mounts and pitch stopper are original parts so quite aged now and will be replaced when I put a new engine in.

The Second pipe was fitted wrapped and at the same time the heat shields were removed from the OE manifold and replaced with heat wrap.

The second pipe does look very corroded and was more corroded then the first. This seems to be due to the wrapping and this pipe does seem to get wet and steam a bit on cold wet days as the wrap dries out. There are no leaks in the engine bay (coolant etc). This was after just over a year.

The comment about the first pipe splitting at the manifold end due to a bolt being present is a good point but its more that an exhaust bolt had been used at the turbo end rather then a stud when Scooby clinic fitted it. So both pipes did in fact split turbo end.

Regarding the wrapping of the up-pipe and engine bay temps I may have miss typed. I did of course mean that the wrapped pipe will be better for engine temps but I am concerned about how quickly it corrodes the pipe. So do I go for corrosion or higher engine temps.

The comments about the gasket thickness makes sense to me as does the one about loosening the manifold off as its fitted. TO be fair it all makes sense and sounds valid.

And no AL or LC.

To try and answer all the questions:

The first up-pipe was not wrapped it was left as it came with no heat shields or wrap. It was fitted with the OE manifold which still had its heat shields in place. It was fitted with a haywood and scott downpipe which has the bracket.

All OE brackets and mounts are present and tight.

The engine mounts and pitch stopper are original parts so quite aged now and will be replaced when I put a new engine in.

The Second pipe was fitted wrapped and at the same time the heat shields were removed from the OE manifold and replaced with heat wrap.

The second pipe does look very corroded and was more corroded then the first. This seems to be due to the wrapping and this pipe does seem to get wet and steam a bit on cold wet days as the wrap dries out. There are no leaks in the engine bay (coolant etc). This was after just over a year.

The comment about the first pipe splitting at the manifold end due to a bolt being present is a good point but its more that an exhaust bolt had been used at the turbo end rather then a stud when Scooby clinic fitted it. So both pipes did in fact split turbo end.

Regarding the wrapping of the up-pipe and engine bay temps I may have miss typed. I did of course mean that the wrapped pipe will be better for engine temps but I am concerned about how quickly it corrodes the pipe. So do I go for corrosion or higher engine temps.

The comments about the gasket thickness makes sense to me as does the one about loosening the manifold off as its fitted. TO be fair it all makes sense and sounds valid.

And no AL or LC.

Last edited by FMJ; 28 November 2013 at 12:48 AM.

#18

Scooby Regular

Join Date: May 2013

Location: welling,kent

Posts: 1,103

Likes: 0

Received 0 Likes

on

0 Posts

Wow lots of replies thanks guys and lots of things to look into.

To try and answer all the questions:

The first up-pipe was not wrapped it was left as it came with no heat shields or wrap. It was fitted with the OE manifold which still had its heat shields in place. It was fitted with a haywood and scott downpipe which has the bracket.

All OE brackets and mounts are present and tight.

The engine mounts and pitch stopper are original parts so quite aged now and will be replaced when I put a new engine in.

The Second pipe was fitted wrapped and at the same time the heat shields were removed from the OE manifold and replaced with heat wrap.

The second pipe does look very corroded and was more corroded then the first. This seems to be due to the wrapping and this pipe does seem to get wet and steam a bit on cold wet days as the wrap dries out. There are no leaks in the engine bay (coolant etc). This was after just over a year.

The comment about the first pipe splitting at the manifold end due to a bolt being present is a good point but its more that an exhaust bolt had been used at the turbo end rather then a stud when Scooby clinic fitted it. So both pipes did in fact split turbo end.

Regarding the wrapping of the up-pipe and engine bay temps I may have miss typed. I did of course mean that the wrapped pipe will be better for engine temps but I am concerned about how quickly it corrodes the pipe. So do I go for corrosion or higher engine temps.

The comments about the gasket thickness makes sense to me as does the one about loosening the manifold off as its fitted. TO be fair it all makes sense and sounds valid.

And no AL or LC.

To try and answer all the questions:

The first up-pipe was not wrapped it was left as it came with no heat shields or wrap. It was fitted with the OE manifold which still had its heat shields in place. It was fitted with a haywood and scott downpipe which has the bracket.

All OE brackets and mounts are present and tight.

The engine mounts and pitch stopper are original parts so quite aged now and will be replaced when I put a new engine in.

The Second pipe was fitted wrapped and at the same time the heat shields were removed from the OE manifold and replaced with heat wrap.

The second pipe does look very corroded and was more corroded then the first. This seems to be due to the wrapping and this pipe does seem to get wet and steam a bit on cold wet days as the wrap dries out. There are no leaks in the engine bay (coolant etc). This was after just over a year.

The comment about the first pipe splitting at the manifold end due to a bolt being present is a good point but its more that an exhaust bolt had been used at the turbo end rather then a stud when Scooby clinic fitted it. So both pipes did in fact split turbo end.

Regarding the wrapping of the up-pipe and engine bay temps I may have miss typed. I did of course mean that the wrapped pipe will be better for engine temps but I am concerned about how quickly it corrodes the pipe. So do I go for corrosion or higher engine temps.

The comments about the gasket thickness makes sense to me as does the one about loosening the manifold off as its fitted. TO be fair it all makes sense and sounds valid.

And no AL or LC.

Thread

Thread Starter

Forum

Replies

Last Post