Swirl Pot - Is my piping correct?

#5

Scooby Regular

iTrader: (8)

Join Date: Feb 2009

Location: N/A

Posts: 2,310

Likes: 0

Received 0 Likes

on

0 Posts

leecalcars where your hoses join to the fuel pump under the panel, how are they connected? Have you altered the connectors or are they push fit on with a clamp?

Thanks

Thanks

Last edited by Saalro; 26 January 2018 at 10:28 PM.

#6

Scooby Regular

iTrader: (12)

Join Date: Apr 2007

Location: Littlehampton

Posts: 2,427

Likes: 0

Received 0 Likes

on

0 Posts

I'm looking at doing mine soon but will be putting a 10 micron filter inline between the lift pump and the surge tank to protect the Bosch 044 and then leaving a filter the the OE location under the bonnet. But how to connect to the factory lines is still under debate!

Trending Topics

#8

Scooby Regular

Thread Starter

iTrader: (21)

Join Date: Oct 2008

Location: Whitby, North Yorkshire

Posts: 3,016

Likes: 0

Received 0 Likes

on

0 Posts

Cheers guys

Saalro, I will be using normal-ish fuel hose, nothing fancy.

BlueBugEye, I've thought about sticking a filter in there too, but I'm going to rely on the lift pumps filter sock.

Saalro, I will be using normal-ish fuel hose, nothing fancy.

BlueBugEye, I've thought about sticking a filter in there too, but I'm going to rely on the lift pumps filter sock.

#9

Scooby Regular

iTrader: (3)

Join Date: Jan 2003

Location: Oss, The Netherlands

Posts: 749

Likes: 0

Received 0 Likes

on

0 Posts

Setup in the picture is not the best actually.

The return to the tank should be at the highest point, the feed from the tank should be below that, and the line going to the front should be at the lowest point.

That way the feed towards the front is (99% of the time) below the level of the fuel.

I've cut of the return to tank, and feed from the intank pump, and welded on -6AN fittings, the balance pump (that sucks fuel from the other half of the tank is stock, and the vapour return is blanked off.

The return to the tank should be at the highest point, the feed from the tank should be below that, and the line going to the front should be at the lowest point.

That way the feed towards the front is (99% of the time) below the level of the fuel.

I've cut of the return to tank, and feed from the intank pump, and welded on -6AN fittings, the balance pump (that sucks fuel from the other half of the tank is stock, and the vapour return is blanked off.

Last edited by Dutch Scooby lover; 10 March 2012 at 03:21 AM.

#13

Scooby Regular

iTrader: (8)

Join Date: Feb 2009

Location: N/A

Posts: 2,310

Likes: 0

Received 0 Likes

on

0 Posts

I've been told by Goodridge and Think Auto (MOCAL) you shouldn't use worm drive type clips with briaded teflon hose.

Dutch Scooby lover, if you have welded on fittings, how is it connected in the engine bay as it is only push fit on the hard lines?

Thanks

Dutch Scooby lover, if you have welded on fittings, how is it connected in the engine bay as it is only push fit on the hard lines?

Thanks

Last edited by Saalro; 26 January 2018 at 10:28 PM.

#14

Scooby Regular

iTrader: (3)

Join Date: Jan 2003

Location: Oss, The Netherlands

Posts: 749

Likes: 0

Received 0 Likes

on

0 Posts

@ Chris, I'm a total idiot.

The piece the pump sits on is also a feed, so your hose routing is indeed correct.

@ Saalro, I used Torques hardline adapters on both ends.

I cut of the fuel pipes in the rear right below the seat base, so I was left with about 10cm of straight hardline, and then fitted these.

http://stores.ebay.co.uk/Torques-U-K...=p4634.c0.m322

I did the same in the front, if you cut of the OEM hardline right near the bulbhead in a way that leaves you as much of straight hardline the torques adapters will work.

The piece the pump sits on is also a feed, so your hose routing is indeed correct.

@ Saalro, I used Torques hardline adapters on both ends.

I cut of the fuel pipes in the rear right below the seat base, so I was left with about 10cm of straight hardline, and then fitted these.

http://stores.ebay.co.uk/Torques-U-K...=p4634.c0.m322

I did the same in the front, if you cut of the OEM hardline right near the bulbhead in a way that leaves you as much of straight hardline the torques adapters will work.

#15

Scooby Regular

iTrader: (8)

Join Date: Feb 2009

Location: N/A

Posts: 2,310

Likes: 0

Received 0 Likes

on

0 Posts

Ahhh awesome, so you don't need to flare the end? Think you may have just solved my problems!

Got any photographs of your setup?

Thanks

Got any photographs of your setup?

Thanks

Last edited by Saalro; 26 January 2018 at 10:28 PM.

#16

Scooby Regular

Thread Starter

iTrader: (21)

Join Date: Oct 2008

Location: Whitby, North Yorkshire

Posts: 3,016

Likes: 0

Received 0 Likes

on

0 Posts

Cheers DSL  can I ask what size the feed and return hard pipes are in the engine bay? Are they both 8mm?

can I ask what size the feed and return hard pipes are in the engine bay? Are they both 8mm?

Steve, I've got some speedflow fittings at the moment in blue/black with -6AN to Push On, but when I fit my swirl pot, I will get Torques fittings, again push on and -6AN, and use Aeroquip hose like this http://item.mobileweb.ebay.co.uk/vie...d=170741674954 as I'm not fussed about braided.

can I ask what size the feed and return hard pipes are in the engine bay? Are they both 8mm?

can I ask what size the feed and return hard pipes are in the engine bay? Are they both 8mm?Steve, I've got some speedflow fittings at the moment in blue/black with -6AN to Push On, but when I fit my swirl pot, I will get Torques fittings, again push on and -6AN, and use Aeroquip hose like this http://item.mobileweb.ebay.co.uk/vie...d=170741674954 as I'm not fussed about braided.

#17

Scooby Regular

iTrader: (3)

Join Date: Jan 2003

Location: Oss, The Netherlands

Posts: 749

Likes: 0

Received 0 Likes

on

0 Posts

I believe they are indeed 8mm, Chris.

@ Sam.

I have some indeed.

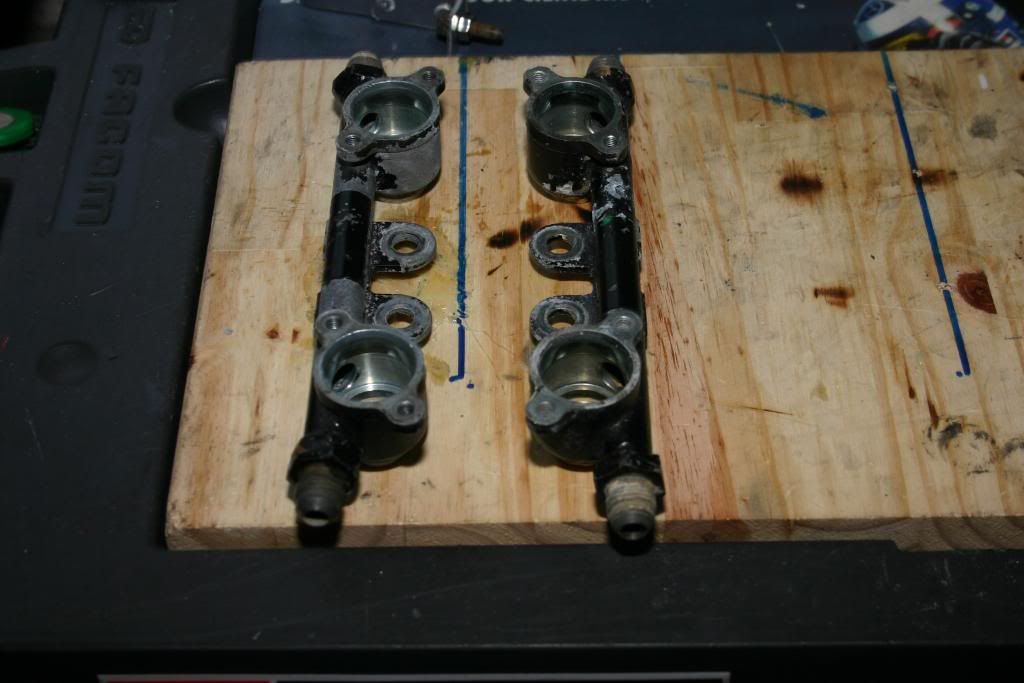

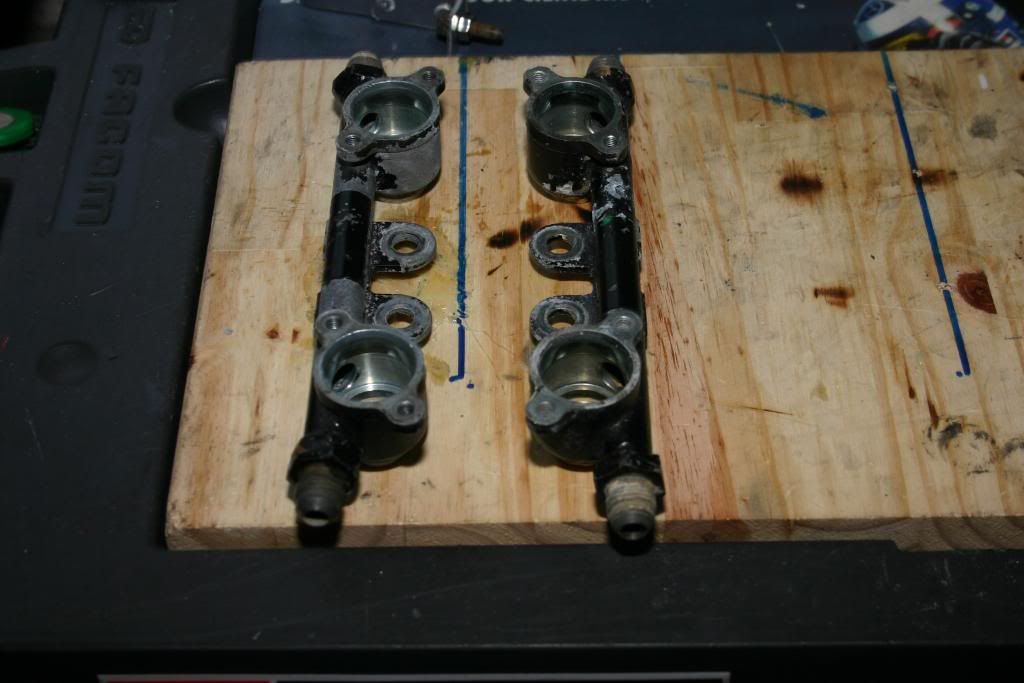

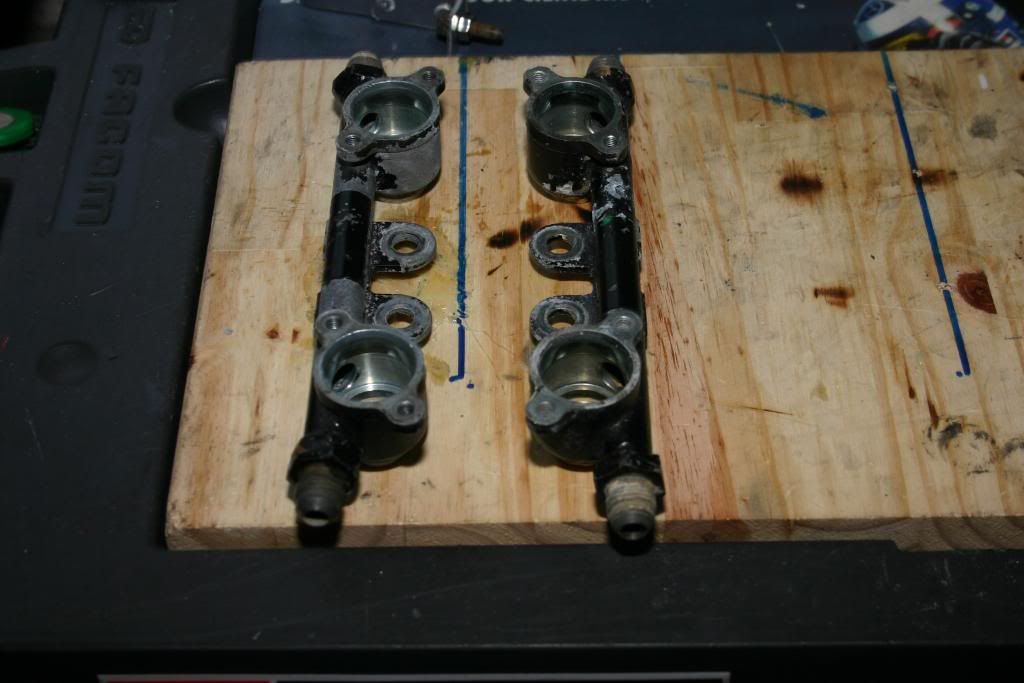

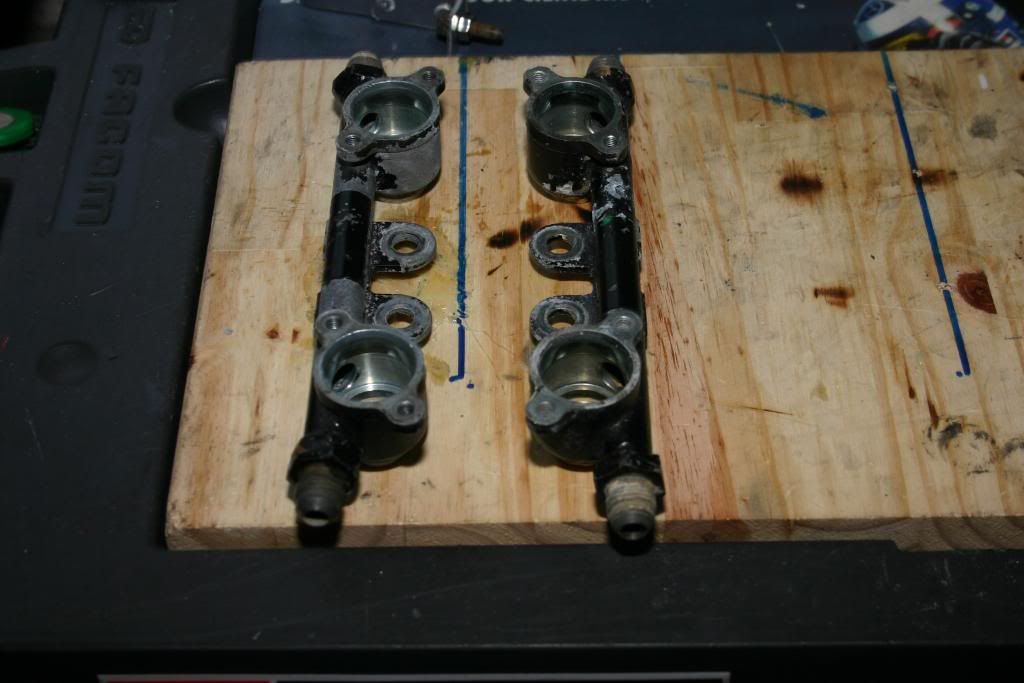

Swirl pot, in the boot, drivers side.

3 port FPR (had a 2 port one, but this cleans up the engine bay a bit)

Fuel feed.

Top line comes from the hardline adapter, the two Y ones each go to one OEM rail with welded on -An6 fittings.

Fuel Rails

Sadly I do not have any pictures of the fuel tank lid with welded on fittings, but if you have any questions just ask them, and I'll try and explain.

@ Sam.

I have some indeed.

Swirl pot, in the boot, drivers side.

3 port FPR (had a 2 port one, but this cleans up the engine bay a bit)

Fuel feed.

Top line comes from the hardline adapter, the two Y ones each go to one OEM rail with welded on -An6 fittings.

Fuel Rails

Sadly I do not have any pictures of the fuel tank lid with welded on fittings, but if you have any questions just ask them, and I'll try and explain.

#18

Scooby Regular

iTrader: (20)

Join Date: Jan 2005

Location: Northumberland

Posts: 1,961

Likes: 0

Received 0 Likes

on

0 Posts

Cheers DSL  can I ask what size the feed and return hard pipes are in the engine bay? Are they both 8mm?

can I ask what size the feed and return hard pipes are in the engine bay? Are they both 8mm?

Steve, I've got some speedflow fittings at the moment in blue/black with -6AN to Push On, but when I fit my swirl pot, I will get Torques fittings, again push on and -6AN, and use Aeroquip hose like this http://item.mobileweb.ebay.co.uk/vie...d=170741674954 as I'm not fussed about braided.

can I ask what size the feed and return hard pipes are in the engine bay? Are they both 8mm?

can I ask what size the feed and return hard pipes are in the engine bay? Are they both 8mm?Steve, I've got some speedflow fittings at the moment in blue/black with -6AN to Push On, but when I fit my swirl pot, I will get Torques fittings, again push on and -6AN, and use Aeroquip hose like this http://item.mobileweb.ebay.co.uk/vie...d=170741674954 as I'm not fussed about braided.

#20

Scooby Regular

iTrader: (8)

Join Date: Feb 2009

Location: N/A

Posts: 2,310

Likes: 0

Received 0 Likes

on

0 Posts

I believe they are indeed 8mm, Chris.

@ Sam.

I have some indeed.

Swirl pot, in the boot, drivers side.

3 port FPR (had a 2 port one, but this cleans up the engine bay a bit)

Fuel feed.

Top line comes from the hardline adapter, the two Y ones each go to one OEM rail with welded on -An6 fittings.

Fuel Rails

Sadly I do not have any pictures of the fuel tank lid with welded on fittings, but if you have any questions just ask them, and I'll try and explain.

@ Sam.

I have some indeed.

Swirl pot, in the boot, drivers side.

3 port FPR (had a 2 port one, but this cleans up the engine bay a bit)

Fuel feed.

Top line comes from the hardline adapter, the two Y ones each go to one OEM rail with welded on -An6 fittings.

Fuel Rails

Sadly I do not have any pictures of the fuel tank lid with welded on fittings, but if you have any questions just ask them, and I'll try and explain.

Thanks

Last edited by Saalro; 26 January 2018 at 10:29 PM.

#21

Scooby Regular

iTrader: (37)

this video The torques fitting is exactly the same. The difficult bit is cutting off the bulb head at the end of the hard line if you don't have the tools.

This is my finished work using Torques hard line adaptor and push on fittings with aeroquip hose,

#23

Scooby Regular

Thread Starter

iTrader: (21)

Join Date: Oct 2008

Location: Whitby, North Yorkshire

Posts: 3,016

Likes: 0

Received 0 Likes

on

0 Posts

What do you mean Sam?

Push fit is just an alternative to using braided. I'm using push fit with the above fittings for ease of use and less cost (for the braided)

Push fit is just an alternative to using braided. I'm using push fit with the above fittings for ease of use and less cost (for the braided)

#24

Scooby Regular

iTrader: (8)

Join Date: Feb 2009

Location: N/A

Posts: 2,310

Likes: 0

Received 0 Likes

on

0 Posts

I thought the whole idea of using braided hose and these fittings was to make a strong system that can hold X amount of pressure. If you have braided hose and fittings that can withstand X amount of pressure, then using push fit would be a weak point in the system.

You have used hard line adaptors above with and then used push fit hosing, why not save the £ and just use hosing and worm drive clips? Or did you want the looks?

Thanks

You have used hard line adaptors above with and then used push fit hosing, why not save the £ and just use hosing and worm drive clips? Or did you want the looks?

Thanks

Last edited by Saalro; 26 January 2018 at 10:29 PM.

#25

Scooby Regular

Thread Starter

iTrader: (21)

Join Date: Oct 2008

Location: Whitby, North Yorkshire

Posts: 3,016

Likes: 0

Received 0 Likes

on

0 Posts

I'm totally not going for looks on my install, just practicality. I'm more than sure the push on fittings can with hold the fuel pressures that most people need?

I might be wrong, but I thought the 'proper' push on fittings like above are miles above standard straight pipe, with hose pushed on with a worm drive clip holding it on (I could be wrong though)

I might be wrong, but I thought the 'proper' push on fittings like above are miles above standard straight pipe, with hose pushed on with a worm drive clip holding it on (I could be wrong though)

#26

Scooby Regular

iTrader: (37)

the only way to get the hose off in the future is to cut it.

the only way to get the hose off in the future is to cut it. Also the Aeroquip hose has a 9.5mm I.D so too big to go on the OEM hard line

#28

Scooby Regular

iTrader: (1)

Join Date: Apr 2005

Location: In the Flatlands of Lincolnshire

Posts: 2,892

Likes: 0

Received 0 Likes

on

0 Posts

One thing I am not sure on is hose sizes, in AN6 8mm pipe? As thinking about using copper pipe and hardline fitting when pipework is external to the car.

Cheers Steve

Thread

Thread Starter

Forum

Replies

Last Post

shorty87

Full Cars Breaking For Spares

19

22 December 2015 11:59 AM

Mattybr5@MB Developments

Full Cars Breaking For Spares

12

18 November 2015 07:03 AM