HDi Hybrid Gt2 FMIC - What a loada crap!!

#1

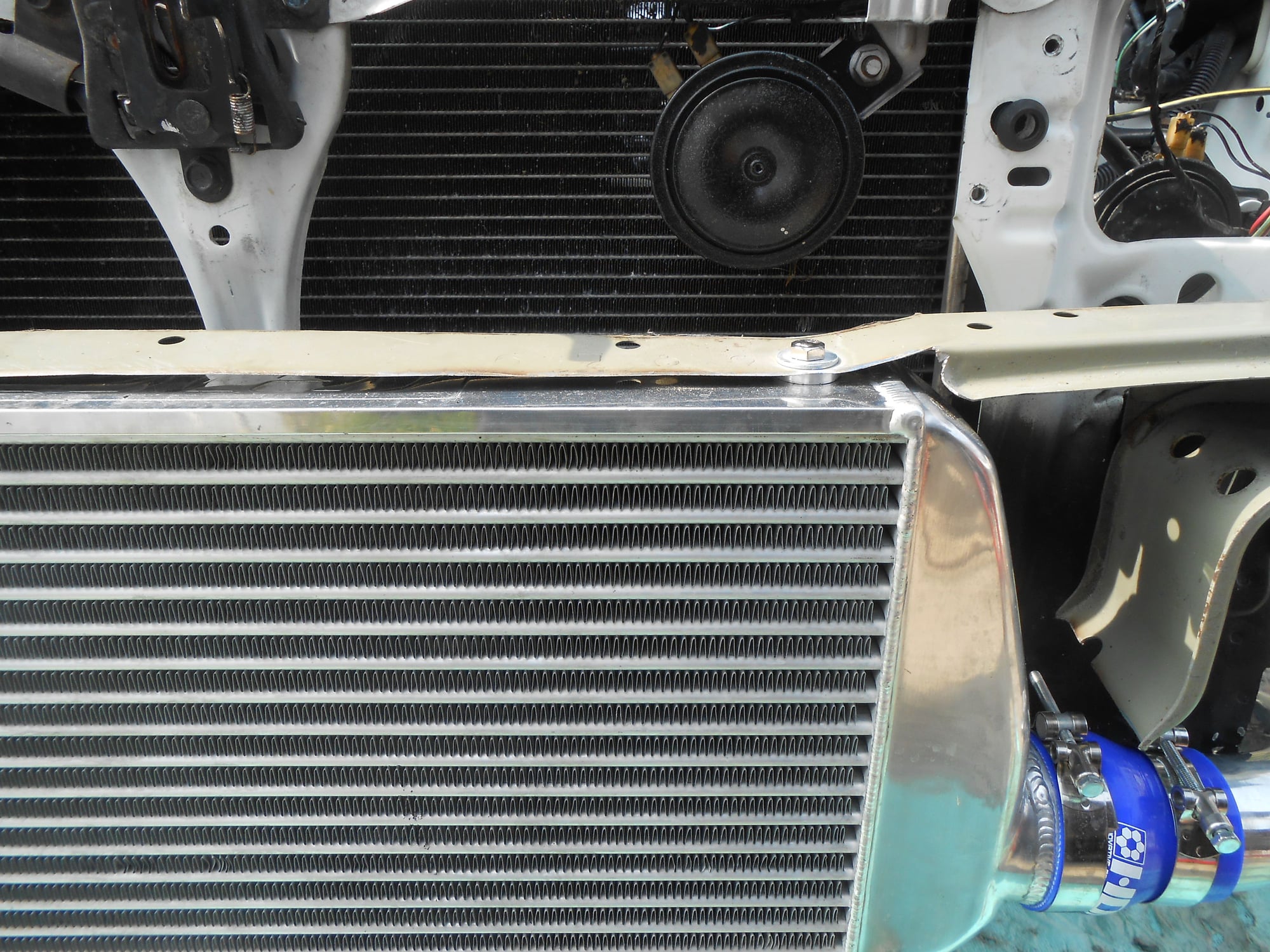

Spent the last couple of weekend trying to fit this sack of crap HDI Fmic kit to my v3 sti.

After hanging the intercooler and f*cking about with that, none of the metal pipes kit fits!!

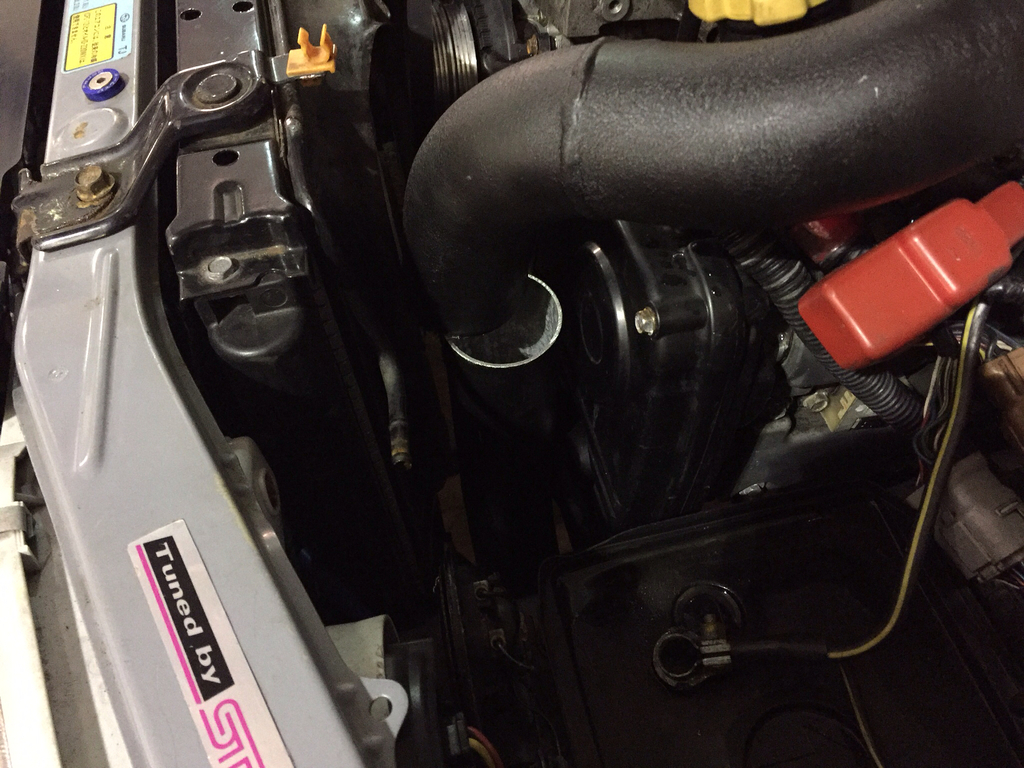

The pipe from the turbo that goes towards the inner wing hit everything on the way through! Master cylinder & water pipe from back of the block. To make things worse it ends up pointing at the abs pump so you cant get the other pipe on it.

That links to the intercooler on the drivers side will fit with a bit of trimming of the front panel etc

The pipe from the inlet manifold is a joke, hits the oil filler, fuel pipes, air con pipes & battery.

Passengers side of the intercooler, the pipe is wedged against the cam belt cover and squeezed in the bottom rad hose and putting pressure on the radiator outlet.

Kinda feel like I've been stitched up with this crappy kit, I would expect it from an ebay kit not a 500 quid kit that everyones been raving about

Anyone else had similar issues? How did you get round it? Either that or anyone wanna buy this sack of crap??

After hanging the intercooler and f*cking about with that, none of the metal pipes kit fits!!

The pipe from the turbo that goes towards the inner wing hit everything on the way through! Master cylinder & water pipe from back of the block. To make things worse it ends up pointing at the abs pump so you cant get the other pipe on it.

That links to the intercooler on the drivers side will fit with a bit of trimming of the front panel etc

The pipe from the inlet manifold is a joke, hits the oil filler, fuel pipes, air con pipes & battery.

Passengers side of the intercooler, the pipe is wedged against the cam belt cover and squeezed in the bottom rad hose and putting pressure on the radiator outlet.

Kinda feel like I've been stitched up with this crappy kit, I would expect it from an ebay kit not a 500 quid kit that everyones been raving about

Anyone else had similar issues? How did you get round it? Either that or anyone wanna buy this sack of crap??

#2

Fitted one to my glanza and had the exact same issues. Crap fit, crap brackets, crap pipework etc etc etc!

Also with the starlet if you mount it with their supplied brackets it sits so far out that you end up with 3mm of bumper left on the bottom!

Also with the starlet if you mount it with their supplied brackets it sits so far out that you end up with 3mm of bumper left on the bottom!

#3

Scooby Regular

iTrader: (5)

Spent the last couple of weekend trying to fit this sack of crap HDI Fmic kit to my v3 sti.

After hanging the intercooler and f*cking about with that, none of the metal pipes kit fits!!

The pipe from the turbo that goes towards the inner wing hit everything on the way through! Master cylinder & water pipe from back of the block. To make things worse it ends up pointing at the abs pump so you cant get the other pipe on it.

That links to the intercooler on the drivers side will fit with a bit of trimming of the front panel etc

The pipe from the inlet manifold is a joke, hits the oil filler, fuel pipes, air con pipes & battery.

Passengers side of the intercooler, the pipe is wedged against the cam belt cover and squeezed in the bottom rad hose and putting pressure on the radiator outlet.

Kinda feel like I've been stitched up with this crappy kit, I would expect it from an ebay kit not a 500 quid kit that everyones been raving about

Anyone else had similar issues? How did you get round it? Either that or anyone wanna buy this sack of crap??

After hanging the intercooler and f*cking about with that, none of the metal pipes kit fits!!

The pipe from the turbo that goes towards the inner wing hit everything on the way through! Master cylinder & water pipe from back of the block. To make things worse it ends up pointing at the abs pump so you cant get the other pipe on it.

That links to the intercooler on the drivers side will fit with a bit of trimming of the front panel etc

The pipe from the inlet manifold is a joke, hits the oil filler, fuel pipes, air con pipes & battery.

Passengers side of the intercooler, the pipe is wedged against the cam belt cover and squeezed in the bottom rad hose and putting pressure on the radiator outlet.

Kinda feel like I've been stitched up with this crappy kit, I would expect it from an ebay kit not a 500 quid kit that everyones been raving about

Anyone else had similar issues? How did you get round it? Either that or anyone wanna buy this sack of crap??

When I fitted a HDI FMIC to a Bug it wasn't exactly a straightforward job but nothing like this. Not much of an advert either if you're hoping someone will buy it off you!

#4

Scooby Regular

iTrader: (2)

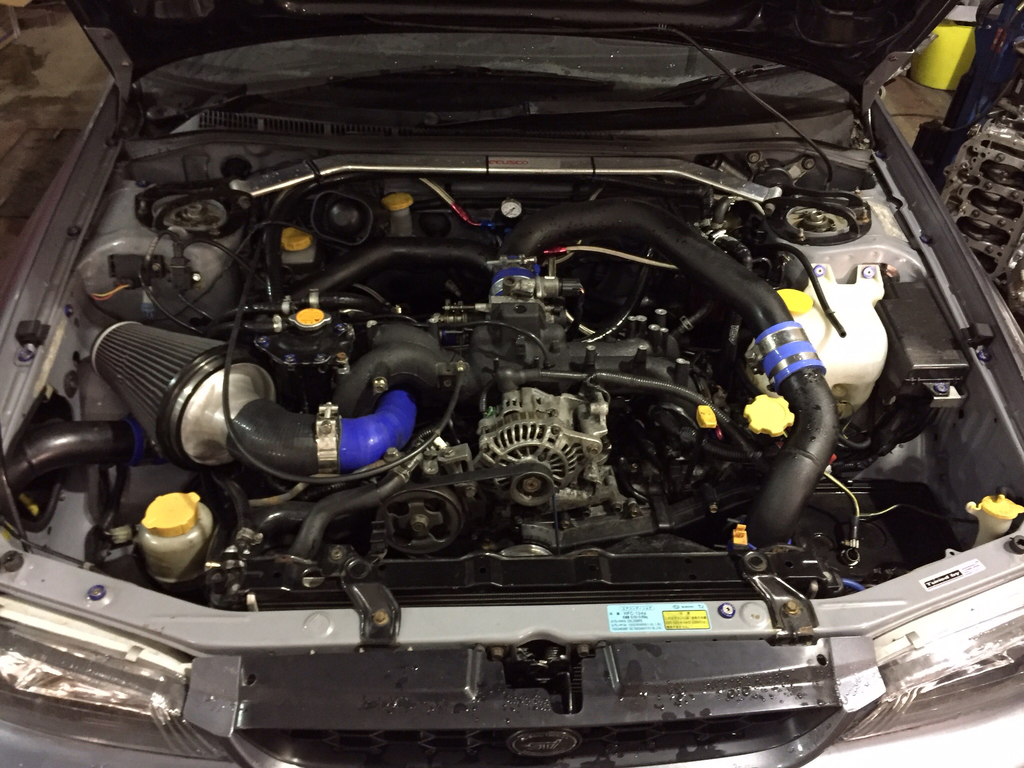

Fitted one to my v2 the ops description sound about right. I thought the poor fit was due to the top inlet td05. Angle grinder essential. It's been on the car nearly two years now. Most of the pipes and clips have been replaced with decent silicone and quality clamps. The clashing pipework has been cut and silicone joiners put in, a vain attempt to stop it clashing with oil filler neck, battery and turbo actuator. I now have issues with pipes blowing off under boost. I'm saving up for a bead roller, they're nearly £100  .

.

The cooler core itself works ok though.

.

.The cooler core itself works ok though.

Last edited by edsel; 20 December 2015 at 05:57 PM.

Trending Topics

#8

I bought mine when first released all pipes fitted ok

Quality kit inlet temps only rise few degrees from cruising to boost

Quality kit inlet temps only rise few degrees from cruising to boost

Last edited by Jaysz; 20 December 2015 at 09:45 PM.

#9

Mines on a classic, so don't be too put off, i've not heard anything bad about the newage kits

Not going for massive power but reaching the limit of the standard top mount

I've always been told that they're on of the best reasonably priced kits, but never thought I would be having this sort of issues.

I've fitted the Autobahn kit to a mates car, had a few issues but nothing like this

I've fitted the Autobahn kit to a mates car, had a few issues but nothing like this

#10

Fitted one to my v2 the ops description sound about right. I thought the poor fit was due to the top inlet td05. Angle grinder essential. It's been on the car nearly two years now. Most of the pipes and clips have been replaced with decent silicone and quality clamps. The clashing pipework has been cut and silicone joiners put in, a vain attempt to stop it clashing with oil filler neck, battery and turbo actuator. I now have issues with pipes blowing off under boost. I'm saving up for a bead roller, they're nearly £100  .

.

The cooler core itself works ok though.

.

.The cooler core itself works ok though.

this is the very reason i fitted the kit that was specifically designed for the 92/96 impreza (cant remember the make off hand) it didn't need any hacking of the inner wing, minimal trimming of the front and does not hang out of the bottom of the bumper like the others do,

as for the bead roller can you make one your self out a pair of old mole grips to save a few ££.

#11

Scooby Regular

iTrader: (2)

this is the very reason i fitted the kit that was specifically designed for the 92/96 impreza (cant remember the make off hand) it didn't need any hacking of the inner wing, minimal trimming of the front and does not hang out of the bottom of the bumper like the others do,

as for the bead roller can you make one your self out a pair of old mole grips to save a few ££.

as for the bead roller can you make one your self out a pair of old mole grips to save a few ££.

#12

I've always been told that they're on of the best reasonably priced kits, but never thought I would be having this sort of issues.

I've fitted the Autobahn kit to a mates car, had a few issues but nothing like this[/QUOTE]

Mine kit is for v3 all pipework fitted

Only part found tricky was trimming bumper

I've fitted the Autobahn kit to a mates car, had a few issues but nothing like this[/QUOTE]

Mine kit is for v3 all pipework fitted

Only part found tricky was trimming bumper

#13

I've had an old APS intercooler kit tucked away in the back of my garage for a couple of years, so I dug it out this afternoon and started laying it out on the car. Everything lines up perfectly, no trimming of anything! So its not like my cars out of shape or been smashed in the past! If only I'd tried fitted this HDi kit last year when I brought it, I'd have sent it straight back and rammed it right up their a*se!

The core is a work of art, but the pipework looks like something you'd find on eBay!

#18

Scooby Regular

iTrader: (31)

I bought one from Harvey many years ago with supplied powder coated pipes. By the time I had finished chopping the pipes the powder coating was severely scratched!

I also had to cut the pipe to the TB in two and add a joiner because it was completely the wrong shape.

I also had to cut the pipe to the TB in two and add a joiner because it was completely the wrong shape.

#24

Scooby Regular

iTrader: (31)

Give over man, it's not a easy job mind but once you get it right it fits, I only had to chop down passenger pipe down a bit behind radiator as was fouling bonnet and filler cap, couple inches off and is now perfect.

The core mounting position has got to be right too, a bit of blood sweat and tears and it's fine.

I havnt tested mine at high boost yet to see if joiners blow off but I'll cross that when it happens.

The core mounting position has got to be right too, a bit of blood sweat and tears and it's fine.

I havnt tested mine at high boost yet to see if joiners blow off but I'll cross that when it happens.

#25

Scooby Regular

iTrader: (13)

If any of you find hoses are constantly blowing on track, esp ones that have a bit of oil in them a get out of jail old school solution is to clean off and line the silicone joiner and the hose with talcum powder.

#28

Scooby Regular

iTrader: (2)

Various silicone hoses and clips have been replaced on mine. As a general tip, a short term solution.

If any of you find hoses are constantly blowing on track, esp ones that have a bit of oil in them a get out of jail old school solution is to clean off and line the silicone joiner and the hose with talcum powder.

If any of you find hoses are constantly blowing on track, esp ones that have a bit of oil in them a get out of jail old school solution is to clean off and line the silicone joiner and the hose with talcum powder.

Micky: Your install is almost identical to mine, I'm now using murray clamps too but on the track they still separate. At one stage I had four clamps holding the top join together but all it did was blow off at the next joint.

Buster: I thought about using contact adhesive after someone suggested I use hairspray. All the joints are close to the turbo and get very hot. I was concerned about catching fire.

Another clash issue I had with the HDI pipes was the bonnet vent bolt rubbing on the cold pipe, more grinding! I disagree with your get over it statement I had to grind too close to the main chassis rail to get the bottom lower pipe to get close to get a half decent fit. The supplied silicone and clamps are poor quality.

Last edited by edsel; 21 December 2015 at 08:44 PM.

#29

Unmapped 12.4s @ 105

iTrader: (29)

Join Date: Apr 2005

Location: Newcastle. 330bhp-289lb/ft @ 1bar boost - 12.4s @ 105mph

Posts: 11,776

Likes: 0

Received 4 Likes

on

4 Posts

Or modify some mole grips.