Project *** Polished Inlet Manifold ***

#1

I am giving my self a project over the winter to have a go at a polished inlet manifold for my classic.

I know this is going to be a big job for me, but i like a challenge.

I am aiming for a clean polished look with as little on as poss.

I raided my dads shed today for some tools and i have..

Grinder

files

hack saw

drimmel

sand paper

eye protection

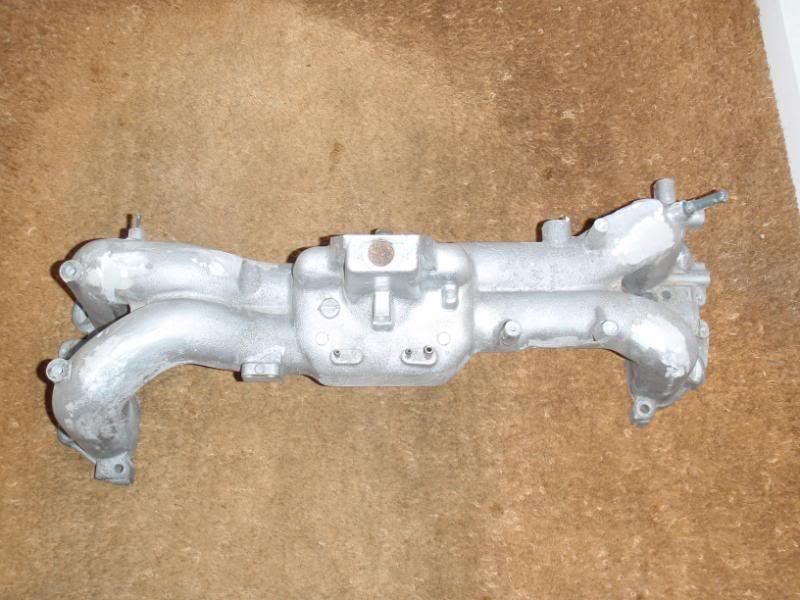

standard classic my99 inlet manifold

this was after around 1-1.5 hours with the grinder and file

I know this is going to be a big job for me, but i like a challenge.

I am aiming for a clean polished look with as little on as poss.

I raided my dads shed today for some tools and i have..

Grinder

files

hack saw

drimmel

sand paper

eye protection

standard classic my99 inlet manifold

this was after around 1-1.5 hours with the grinder and file

#3

Scooby Senior

iTrader: (51)

Join Date: Nov 2005

Location: Wherever I park my car, that's my home

Posts: 20,491

Likes: 0

Received 2 Likes

on

2 Posts

Good luck, it's hard work but if you get a cheap polishing kit from ebay (about £20) that attached to a power drill you can finish it off a treat. I went mad earlier this year did my induction kit, TMIC and diff guard

#4

Scooby Regular

iTrader: (19)

Well the HT leads are designed to meet the box in the middle with the left leads longer as you look at the block, so at a guess you would have to find longer HT leads from somewhere as it is normally a tight fit anyway. And dont forget the plug connector that goes into the box

#5

im just wondering about feeding the ht leads under/between the legs of the inlet manifold and have the black box under the inlet/behind manifold around the same sort of area as standard. i was wondering if it needed to be grounded at all?

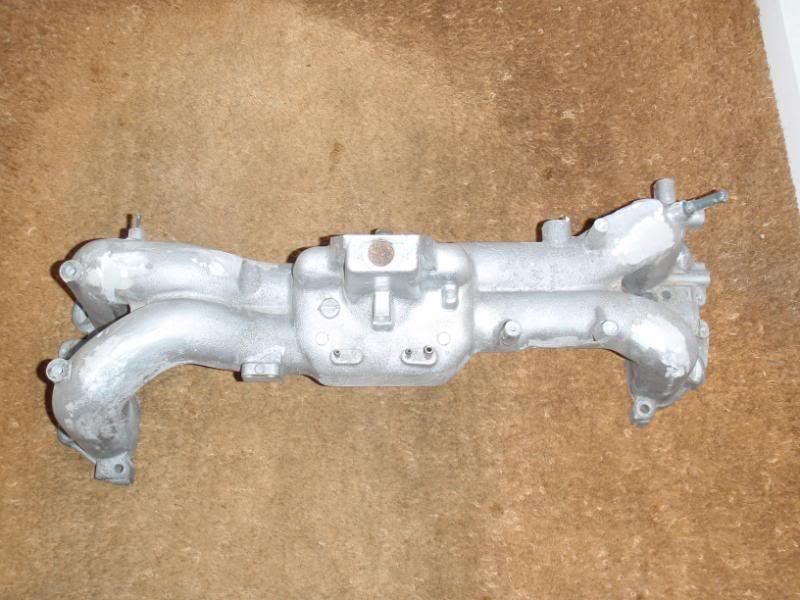

this is a pic of what i have on my inlet at the mo

this is a pic of what i have on my inlet at the mo

#6

Scooby Regular

iTrader: (19)

Definately needs to be grounded. Have a look at this website. Tim moght be able to source longer HT leads

Scoobyparts Ltd MAGNECOR 8mm PERFORMANCE HT LEAD SET 40205

Scoobyparts Ltd MAGNECOR 8mm PERFORMANCE HT LEAD SET 40205

Trending Topics

#10

Moderator

iTrader: (15)

I'm still part way into mine and hope to finish it through the winter months, it's a big job  but well worth it when you finish. I have some insulated spacers to go back under mine when I change it because I figured if it's coming off I just as well make the most of things.

but well worth it when you finish. I have some insulated spacers to go back under mine when I change it because I figured if it's coming off I just as well make the most of things.

but well worth it when you finish. I have some insulated spacers to go back under mine when I change it because I figured if it's coming off I just as well make the most of things.

but well worth it when you finish. I have some insulated spacers to go back under mine when I change it because I figured if it's coming off I just as well make the most of things.

#11

#23

Moderator

iTrader: (15)

I've been trying to get motivated on mine since the summer I got part way in and it did my head in slightly

hopefully now over the winter I can finish it off, far from easy and a ton of patience required for sure.

hopefully now over the winter I can finish it off, far from easy and a ton of patience required for sure.

I simply went for a full polish on a few areas straight off to see how much prep was really needed now I need to work back a few steps then go for the finished polish again.

Good luck there

hopefully now over the winter I can finish it off, far from easy and a ton of patience required for sure.

hopefully now over the winter I can finish it off, far from easy and a ton of patience required for sure.I simply went for a full polish on a few areas straight off to see how much prep was really needed now I need to work back a few steps then go for the finished polish again.

Good luck there

Last edited by Silver Scooby Sport; 06 November 2009 at 06:37 PM.

#24

looking good there, mine is getting there, have had a few days off now as it has been wet outside, and i nearly got killed the other day when i started it on the kitchen table lol

have started to go over with sand paper. it is when you get it nice and smooth apart form one or two small scrach marks in the smooth finish that really bugs me!!

have started to go over with sand paper. it is when you get it nice and smooth apart form one or two small scrach marks in the smooth finish that really bugs me!!

#26

you know them little holes you get in the casting when you start to smooth it down, will i had some on the front that were really bugging me so i started to try and sand them away.

and the result.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

ouch

am going to see if i can get the front cut out and a new bit of alloy weilded in

bugger

and the result.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

ouch

am going to see if i can get the front cut out and a new bit of alloy weilded in

bugger

#30