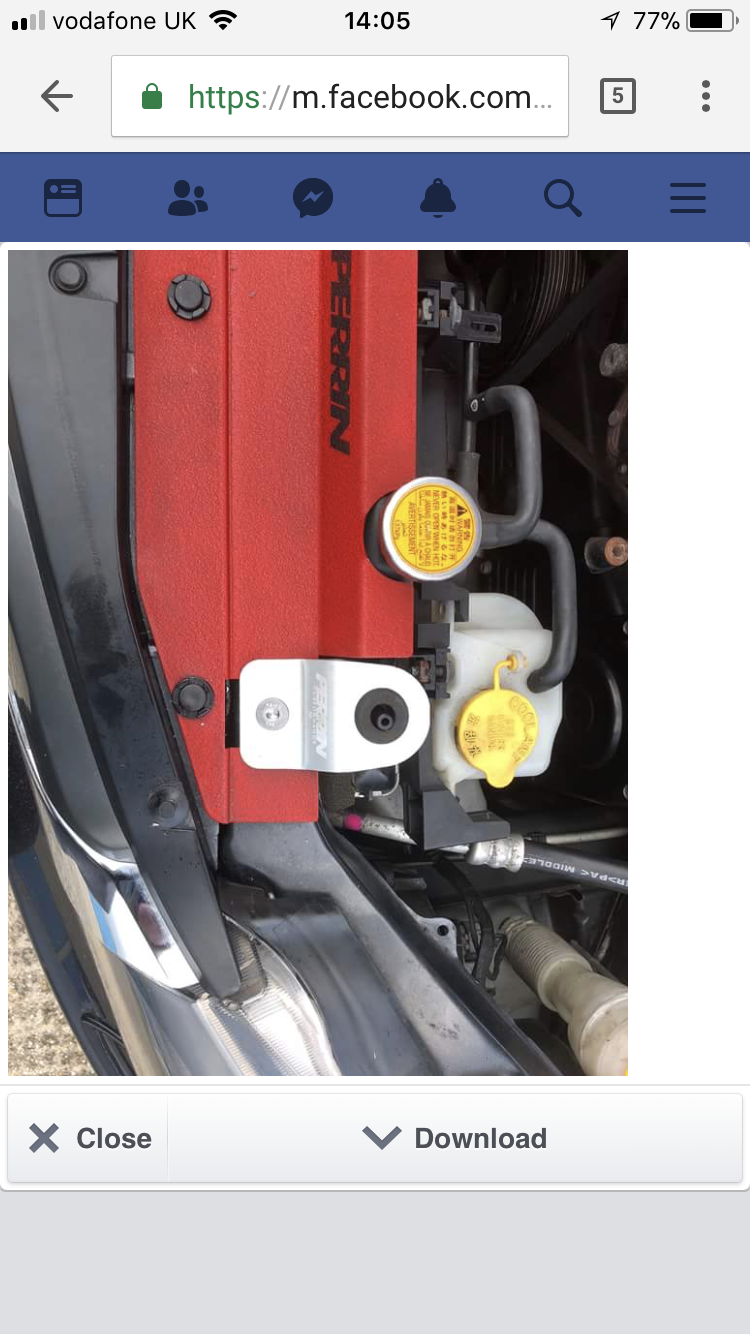

Snapped bolt

#1

Scooby Regular

Thread Starter

Need some help.

Went to put some radiator stays on me motor when the bolt head snapped off. Any help on removing the bolts, Iíd be grateful.

Cheers

#5

Scooby Regular

Thread Starter

I’ll give it another go tomorrow with mole grips and a bit of heat. If that don’t work I may drill a bit deeper into the bolt, bang a screw extractor into their a bit and see if I can unscrew it with mole grips from the top

Trending Topics

#8

#10

Scooby Regular

iTrader: (2)

Did this on mine.

Soak in WD40 overnight, use mole grips to turn it out towards the rusted end, ie: further IN. Then you aren't trying to drag the badly rusted bit tyhrough the threads Mine came out relatively easily.

Mine came out relatively easily.

Replace all such bolts with stainless, they are M8 x 16 or M8 x 20 iirc. Might be M6. Screwfix. Bag of ten, under £2.

Soak in WD40 overnight, use mole grips to turn it out towards the rusted end, ie: further IN. Then you aren't trying to drag the badly rusted bit tyhrough the threads

Mine came out relatively easily.

Mine came out relatively easily.Replace all such bolts with stainless, they are M8 x 16 or M8 x 20 iirc. Might be M6. Screwfix. Bag of ten, under £2.

#11

Scooby Regular

Thread Starter

Cheers mate.

The plan was too replace all the bolts.a majority of the bolt is already out at the bottom of the bolt, so Iím hoping that some wd40 like you said and a turn of some mole grips will loosen it up.Cheers

#12

Scooby Regular

iTrader: (3)

Err, why not?

Owning and maintaining 3 cars the newest of which is 12 years old my blow torch gets used quite often to successfully release stubborn bolts/nuts.

I'm a mech fitter to trade and after all the usual tricks heat has its place before resorting to destructive methods of removal - and in my experience it has a pretty good rate of success.

Owning and maintaining 3 cars the newest of which is 12 years old my blow torch gets used quite often to successfully release stubborn bolts/nuts.

I'm a mech fitter to trade and after all the usual tricks heat has its place before resorting to destructive methods of removal - and in my experience it has a pretty good rate of success.

#13

Scooby Regular

iTrader: (1)

Originally Posted by Skoobie Dhu

Err, why not?

Owning and maintaining 3 cars the newest of which is 12 years old my blow torch gets used quite often to successfully release stubborn bolts/nuts.

I'm a mech fitter to trade and after all the usual tricks heat has its place before resorting to destructive methods of removal - and in my experience it has a pretty good rate of success.

Owning and maintaining 3 cars the newest of which is 12 years old my blow torch gets used quite often to successfully release stubborn bolts/nuts.

I'm a mech fitter to trade and after all the usual tricks heat has its place before resorting to destructive methods of removal - and in my experience it has a pretty good rate of success.

#15

Scooby Regular

Join Date: Nov 2011

Location: auchenblae

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

Stainless steel bolts especialy the crap A" grade sold by default are not as strong as carbon steel that you are using. Therefore two problems.

1) if there is a high load on the bolt it will not have the strenght of the existing one and the grade A2 also has less give and snaps easier.

2) You will screw the A2 stainless into the existing carbon steel and you will get differential corrosion due to the dissimilar metal.

It would be much better to use the normal Carbon steel grade 8.8 bolt and use an anti seize compound on the threads.

1) if there is a high load on the bolt it will not have the strenght of the existing one and the grade A2 also has less give and snaps easier.

2) You will screw the A2 stainless into the existing carbon steel and you will get differential corrosion due to the dissimilar metal.

It would be much better to use the normal Carbon steel grade 8.8 bolt and use an anti seize compound on the threads.

#16

Scooby Regular

Thread Starter

Iím gonna change the majority of the bolts in the bay at some point. Iíve found a company in the USA who sell a complete set for a reasonable price, stainless I think, the company is called z spec design.

What if I was too use anti seize on stainless bolts ?

#17

Scooby Regular

Join Date: Nov 2011

Location: auchenblae

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

If you decided to use bolts with less strength and that are more brittle i.e. stainless steel you have the problem of galling where the stainless steel nuts and stainless steel bolts welds the threads together.

You also have a similar problem on the areas where you screw stainless steel into carbon steel.

Therefore you must get anti galling paste for the stainless steel to stainless steel bolt ups and you also need to get a compound to stop the dissimilar metal corrosion when you bolt stainless steel into carbon steel.

I will leave you to search for the best paste for each duty but do not install without the proper paste.

You also have a similar problem on the areas where you screw stainless steel into carbon steel.

Therefore you must get anti galling paste for the stainless steel to stainless steel bolt ups and you also need to get a compound to stop the dissimilar metal corrosion when you bolt stainless steel into carbon steel.

I will leave you to search for the best paste for each duty but do not install without the proper paste.

Last edited by drummog; 15 January 2018 at 07:07 PM.

Thread

Thread Starter

Forum

Replies

Last Post

greenprodrive

General Technical

1

15 August 2006 11:06 PM

Iíll take a look

Iíll take a look