Engine Stage 3

#31

On-Track - ScoobyLive 2007

With the ScoobyLive 2006 Handling Champion place under our belt with the 2ltr engine, the pressure was really on this year to maintain this previous event win. Perhaps too much "self made" pressure with hindsight!

The class of car / drivers competing this year was much greater than in 2006, which in itself compounded the issue. That coupled with the fact that the car had no set-up time devoted to it (what with the first stage only just been completed) and hardly any driver time... this year was going to be a challenge.

As per 2006 and to circumvent *some* pressure, instead of me driving the car another would be drafted in.

The plan in 2006 was always for Simon to drive, but unfortunately due to a nasty accident, saw him with his leg in plaster..... not an ideal combination for driving a car around a handling circuit!

With Simon fit and well for 2007 the pressure was on him to perform on the tight ScoobyLive handling circuit.

We had actually planned for a shakedown at Prodrive's tight handling circuit, but again due to time issues this was not to be. In essence the car was to be driven with the same suspension settings as was used at 2006 TunerGP at Snetterton.... not our greatest move.

Perhaps we should of not entered the car for an event like this, what with the new set-up only just been completed and running in finished, no real set-up time and certainly very little driver time. Never shying away from putting the car through it's paces, we still decided that above all else we would be able to gain valuable feedback and of course routine testing of the new platform.

Simon and car did an admirable job on the day considering. The biggest issue on the day was that of the suspension set-up. It was plainly obvious now that some adjustment would need to be made to ensure the car behaved as expected with the increase in power / torque. This would require more testing and set-up time. All said and done, the car was placed 5th overall on the Handling Circuit, just missing out on a Top 4 Final place. Against 90+ Subaru's, we did not think that was all bad...... 1st would of been nice though!

Simon and car did an admirable job on the day considering. The biggest issue on the day was that of the suspension set-up. It was plainly obvious now that some adjustment would need to be made to ensure the car behaved as expected with the increase in power / torque. This would require more testing and set-up time. All said and done, the car was placed 5th overall on the Handling Circuit, just missing out on a Top 4 Final place. Against 90+ Subaru's, we did not think that was all bad...... 1st would of been nice though!

It was Simon's first time with the new set-up and apart from the suspension adjustment that was required, Simon commented on how smooth yet grunty the car was.

It was Simon's first time with the new set-up and apart from the suspension adjustment that was required, Simon commented on how smooth yet grunty the car was.

Once again the car travelled 260 miles and competed at an event with no major issues.... another positive point taken from the weekend.

We were now starting to gather a lot of feedback and we already knew some areas that we could improve on. With the next event of the year being the prestigous Ten Of The Best competition in July, the car returned back to PowerStation to complete the next round of testing and modifications.

With the ScoobyLive 2006 Handling Champion place under our belt with the 2ltr engine, the pressure was really on this year to maintain this previous event win. Perhaps too much "self made" pressure with hindsight!

The class of car / drivers competing this year was much greater than in 2006, which in itself compounded the issue. That coupled with the fact that the car had no set-up time devoted to it (what with the first stage only just been completed) and hardly any driver time... this year was going to be a challenge.

As per 2006 and to circumvent *some* pressure, instead of me driving the car another would be drafted in.

The plan in 2006 was always for Simon to drive, but unfortunately due to a nasty accident, saw him with his leg in plaster..... not an ideal combination for driving a car around a handling circuit!

With Simon fit and well for 2007 the pressure was on him to perform on the tight ScoobyLive handling circuit.

We had actually planned for a shakedown at Prodrive's tight handling circuit, but again due to time issues this was not to be. In essence the car was to be driven with the same suspension settings as was used at 2006 TunerGP at Snetterton.... not our greatest move.

Perhaps we should of not entered the car for an event like this, what with the new set-up only just been completed and running in finished, no real set-up time and certainly very little driver time. Never shying away from putting the car through it's paces, we still decided that above all else we would be able to gain valuable feedback and of course routine testing of the new platform.

Once again the car travelled 260 miles and competed at an event with no major issues.... another positive point taken from the weekend.

We were now starting to gather a lot of feedback and we already knew some areas that we could improve on. With the next event of the year being the prestigous Ten Of The Best competition in July, the car returned back to PowerStation to complete the next round of testing and modifications.

Last edited by ex-webby; 05 February 2008 at 11:07 PM.

#32

TEST 2 – As Per TEST1 plus different AET GT30 Turbo, uprated fuel system and remapping – Overview

Ok.... so we knew we had to change the suspension set-up for the next time the car was on track. Fortunately that is a relatively easy task to do with the AST's, especially if you have PowerStation at the ready. It was decided that minor tweaks would be done immediately for road use, but adjustments would be made on the day at the next event (based on feedback attained).

Part of the partnership with AET was to test and trial different turbo set-ups, so with some feedback on the initial turbo, AET sent us another turbo to try and improve the topend power but keeping the existing response sustained by the first AET turbo.

As the fuel system was operating on standard fuel pressure to feed the injectors, we knew that the 800cc injectors were approaching their limits (dictated by the injector duty cycle required). With this in mind Litchfield Imports sourced larger injectors to give us more of a safety margin. Together with larger injectors, PowerStation suggested it was an ideal time to think about the entire fuel delivery system..... especially with the emphasis on track use.

Turbo MKII

AET already had some ideas on what could be done to aid mid and topend range power / torque, so we were quite surprised when we received a new turbo to test.

Still within the standard fit remit, the turbo looked exactly the same..... I have to be totally honest and say at this point (based on the size, and yes I know we had been here before) I never thought this newer turbo would meet the requirements (500bhp minimum was being banded around).

After a number of conversations with AET, they assured me that this was certainly different to the first turbo, albeit the physical outward look was exactly the same. The closing comment was "Shaun.... just put it on and see what happens!".

Since the newer turbo was exactly the same dimensions as the first one coming out, the process of swapping them over was very painless.

With the newer turbo in place, we were eager to get mapping..... unfortunately other areas also needed modifying to suit.

Ok.... so we knew we had to change the suspension set-up for the next time the car was on track. Fortunately that is a relatively easy task to do with the AST's, especially if you have PowerStation at the ready. It was decided that minor tweaks would be done immediately for road use, but adjustments would be made on the day at the next event (based on feedback attained).

Part of the partnership with AET was to test and trial different turbo set-ups, so with some feedback on the initial turbo, AET sent us another turbo to try and improve the topend power but keeping the existing response sustained by the first AET turbo.

As the fuel system was operating on standard fuel pressure to feed the injectors, we knew that the 800cc injectors were approaching their limits (dictated by the injector duty cycle required). With this in mind Litchfield Imports sourced larger injectors to give us more of a safety margin. Together with larger injectors, PowerStation suggested it was an ideal time to think about the entire fuel delivery system..... especially with the emphasis on track use.

Turbo MKII

AET already had some ideas on what could be done to aid mid and topend range power / torque, so we were quite surprised when we received a new turbo to test.

Still within the standard fit remit, the turbo looked exactly the same..... I have to be totally honest and say at this point (based on the size, and yes I know we had been here before) I never thought this newer turbo would meet the requirements (500bhp minimum was being banded around).

After a number of conversations with AET, they assured me that this was certainly different to the first turbo, albeit the physical outward look was exactly the same. The closing comment was "Shaun.... just put it on and see what happens!".

Since the newer turbo was exactly the same dimensions as the first one coming out, the process of swapping them over was very painless.

With the newer turbo in place, we were eager to get mapping..... unfortunately other areas also needed modifying to suit.

Last edited by ex-webby; 05 February 2008 at 11:08 PM.

#33

1150cc Injectors and Uprated Fuel Delivery System

As already stated, we knew that the existing 800cc injectors at standard fuel pressure were already running close to their limits. With this in mind we had two options (keeping with standard fuel pressure). One would be to go for an eight injector set-up (same as the Type25 Race Car) and the other option would be to go for even larger injectors.

Based on cost, we decided to try and source larger injectors.

The problem with even larger injectors is that the ECU and engine can struggle to meter and/or burn the fuel supplied by virtual "hosepipes" on idle and part throttle. This is even a known problem with the existing 800cc injectors (but was overcome by PowerStation with careful ECUTEK mapping). Based on what we required the next step up was in the form of 1150cc Injectors.... some 43% larger flow rate! Whilst this would supply enough fuel for our needs, safely, concerns were about the issues that the ECU would have in controlling these and the spray pattern used to aid the combustion process. After a lot of research and phone calls, Litchfield sourced some flow matched 1150cc injectors from the US, which by all accounts would provide exactly what was required.

With the injectors supplied (but yet to be tested), PowerStation moved on to their primary goal, that of uprating the fuel delivery system.

As explained earlier, the original Spec C "in tank" fuel pump coped fine with the first run of modifications at this level. PowerStation were happy with the pump, but knew that it was now time to ensure that the fuel delivery would not be compromised on track.

As well as ensuring that the fuel pump can supply enough fuel, you must also ensure (similarly as with the oil supply system) that you combat against any fuel surge experienced on track. Much the same as previously discussed with the oil system delivery upgrades, fuel surge (for the same reasons) can happen whilst on track..... with similar detrimental affects to reliability.

To combat fuel surge and ensure a reliable supply of fuel to the injectors, PowerStation installed an external Bosch fuel pump (whilst keeping the standard Spec C "in tank" pump as the draw pump) and swirl pot.

To combat fuel surge and ensure a reliable supply of fuel to the injectors, PowerStation installed an external Bosch fuel pump (whilst keeping the standard Spec C "in tank" pump as the draw pump) and swirl pot.

Ok... whilst it may be straight forward to understand why an external (high power / flow) fuel pump was to be installed to aid continuous fuel flow, what is a swirl pot?

Fuel surge happens when (for instance) you go around a corner on track, with say 1/4 tank of fuel, and you notice a miss. This miss is caused by the fuel being thrown in to one side of the tank, thus not allowing the fuel pick up to be submersed in fuel, thus allowing air to be pumped to the injectors. This is known as fuel surge and is BAD!

Fuel surge happens when (for instance) you go around a corner on track, with say 1/4 tank of fuel, and you notice a miss. This miss is caused by the fuel being thrown in to one side of the tank, thus not allowing the fuel pick up to be submersed in fuel, thus allowing air to be pumped to the injectors. This is known as fuel surge and is BAD!

As already stated, we knew that the existing 800cc injectors at standard fuel pressure were already running close to their limits. With this in mind we had two options (keeping with standard fuel pressure). One would be to go for an eight injector set-up (same as the Type25 Race Car) and the other option would be to go for even larger injectors.

Based on cost, we decided to try and source larger injectors.

The problem with even larger injectors is that the ECU and engine can struggle to meter and/or burn the fuel supplied by virtual "hosepipes" on idle and part throttle. This is even a known problem with the existing 800cc injectors (but was overcome by PowerStation with careful ECUTEK mapping). Based on what we required the next step up was in the form of 1150cc Injectors.... some 43% larger flow rate! Whilst this would supply enough fuel for our needs, safely, concerns were about the issues that the ECU would have in controlling these and the spray pattern used to aid the combustion process. After a lot of research and phone calls, Litchfield sourced some flow matched 1150cc injectors from the US, which by all accounts would provide exactly what was required.

With the injectors supplied (but yet to be tested), PowerStation moved on to their primary goal, that of uprating the fuel delivery system.

As explained earlier, the original Spec C "in tank" fuel pump coped fine with the first run of modifications at this level. PowerStation were happy with the pump, but knew that it was now time to ensure that the fuel delivery would not be compromised on track.

As well as ensuring that the fuel pump can supply enough fuel, you must also ensure (similarly as with the oil supply system) that you combat against any fuel surge experienced on track. Much the same as previously discussed with the oil system delivery upgrades, fuel surge (for the same reasons) can happen whilst on track..... with similar detrimental affects to reliability.

Ok... whilst it may be straight forward to understand why an external (high power / flow) fuel pump was to be installed to aid continuous fuel flow, what is a swirl pot?

Last edited by ex-webby; 05 February 2008 at 11:09 PM.

#34

With the new Bosch fuel pump (supplied by API) and the Forge Motorsport Swirl Pot very cleanly installed by PowerStation within the back of the boot, the next stage was to get the car back on the rollers for more intensive mapping, to both improve on what had been mapped previously and to also take in to account the new anxillarys.

Mapping

Things now started to prove more difficult for the standard ECU and ECUTEK to deal with, now the injectors had been increased to virtual hosepipes. Other issues around the existing MAF (Mass Air Flow meter) based airflow system was also becoming apparant at this level.

Forever trying to keep pushing, PowerStation perseveared.

After a number of rescaling issues were completed (of MAF and injectors), ignition and boost maps were tailored to suit. It had now become time for the first real power runs based on TEST2 changes.

At this stage of modifications, it was the first time that PowerStation had commented on the abilities of the standard ECU. Whilst it was still coping with what had been thrown at it, they feared that certain compromises were now taking place. Perhaps it was time in the near future to consider a replacement ECU.

TEST 2 – As Per TEST1 plus different AET GT30 Turbo, uprated fuel system and remapping – Summary of Spec

AET Turbo

1150cc Injectors

Hyperflow Induction Kit

Hyperflow FMIC

SFS inlet hose

Miltek 3" Decat Exhaust System

ECUTEK remapped ECU

Peak Boost - 1.70bar

Fuel - VPower

TEST 2 figure achieved was 522.4bhp @ Flywheel with 710.1Nm (523.67 lb ft) of torque

Last edited by ex-webby; 05 February 2008 at 11:10 PM.

#35

TEST 2 – As Per TEST1 plus different AET GT30 Turbo, uprated fuel system and remapping – Comments

TEST 2 +41.2bhp +64.82lbft (peak) over TEST1

Difficult to put in to words..... but how about double W O W!!!

We had broke the 500 barrier!

As with most dyno readings, whilst the peak figures had impressively increased, the peak figures do not tell the whole story in isolation. Saying this though, the peak figures gained would be as good as you would expect from an initial Stage 1 conversion, and we were getting these gains after other mods after already achieving a whopping circa 100+bhp / 100+lbft with the first part of the Stage 3 mods. This provided around 150bhp / 165lbft increase over what was achieved during Stage 2.

Ok, thats enough about the impressive peak increases in this context.... what about other areas?!

There is no point in having increases in peak figures if the power suffers elsewhere.... how good was this newest AET Turbo around the rest of the curve?

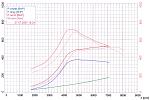

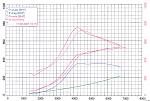

Looking at the overlay graph to the right, it is easy to see that this turbo was certainly not all blow and no go. The graph has Test2 overlayed against Test1 (and yes, Test2 is the earlier spooling and higher power rated line). Whatever AET did to the specification of the newest turbo, it certainly worked. With increases of over 80bhp / 90lbft through points in the rev range, it is clearly noticeable how much better this latest set-up is over Test1.

Looking at the overlay graph to the right, it is easy to see that this turbo was certainly not all blow and no go. The graph has Test2 overlayed against Test1 (and yes, Test2 is the earlier spooling and higher power rated line). Whatever AET did to the specification of the newest turbo, it certainly worked. With increases of over 80bhp / 90lbft through points in the rev range, it is clearly noticeable how much better this latest set-up is over Test1.

Some of you may realise that we ran more boost with Test2 than we did Test1, which is absolutely correct, and some of you may suggest this is only helping increase the figures so not a true reflection of the new turbo. Yes we did run more boost, but only because the new turbo would enable us to safely and easier. One of the areas that was noted by PowerStation was the fact that the newer turbo certainly responded better to boost and made power much more easily. If you look at the graph to the right again, it clearly shows massive increases in power and torque earlier on in the rev range (from as early as 2000rpm)..... now that is not all down to boost, and just goes to show how much better this new turbo is. Boost was up (over Test1) in the initial peak by .1bar, mid-range by .1bar and top end .2bar.

Comparing what we have ever achieved throughout the whole of the engine modifications, we now had more grunt from 2000rpm than we have ever done. I appreciate things have changed massively since the beginning, but to have a set-up that not only gives better power from 2000rpm but also produces well over 500bhp is something not to be sniffed at.... especially when you are comparing lowdown grunt with that of an extremely sorted 2ltr twin scroll set-up.

TEST 2 +41.2bhp +64.82lbft (peak) over TEST1

Difficult to put in to words..... but how about double W O W!!!

We had broke the 500 barrier!

As with most dyno readings, whilst the peak figures had impressively increased, the peak figures do not tell the whole story in isolation. Saying this though, the peak figures gained would be as good as you would expect from an initial Stage 1 conversion, and we were getting these gains after other mods after already achieving a whopping circa 100+bhp / 100+lbft with the first part of the Stage 3 mods. This provided around 150bhp / 165lbft increase over what was achieved during Stage 2.

Ok, thats enough about the impressive peak increases in this context.... what about other areas?!

There is no point in having increases in peak figures if the power suffers elsewhere.... how good was this newest AET Turbo around the rest of the curve?

Some of you may realise that we ran more boost with Test2 than we did Test1, which is absolutely correct, and some of you may suggest this is only helping increase the figures so not a true reflection of the new turbo. Yes we did run more boost, but only because the new turbo would enable us to safely and easier. One of the areas that was noted by PowerStation was the fact that the newer turbo certainly responded better to boost and made power much more easily. If you look at the graph to the right again, it clearly shows massive increases in power and torque earlier on in the rev range (from as early as 2000rpm)..... now that is not all down to boost, and just goes to show how much better this new turbo is. Boost was up (over Test1) in the initial peak by .1bar, mid-range by .1bar and top end .2bar.

Comparing what we have ever achieved throughout the whole of the engine modifications, we now had more grunt from 2000rpm than we have ever done. I appreciate things have changed massively since the beginning, but to have a set-up that not only gives better power from 2000rpm but also produces well over 500bhp is something not to be sniffed at.... especially when you are comparing lowdown grunt with that of an extremely sorted 2ltr twin scroll set-up.

Last edited by ex-webby; 05 February 2008 at 11:10 PM.

#36

Another area we have not really touched on is the way the Cosworth engine produces the power. As this set-up proves (if you look carefully enough), gone are the days of having a 2.5ltr engine that neither makes good power at the top end nor revs well. This total combination clearly shows on the graphs that not only is power made past 7000rpm, but the drop off is very little even to 8000rpm. That means more useable power, through a wider rev range, which ultimately makes a quicker car.

We have not really made much out of the fuel area either to be honest, but can I please underline these figures are attained on plain old VPower!

It doesnt matter how you look at this, the power delivery attained is nothing short of brilliant, especially considering the fuel type and nature of the drop-in turbo.

TEST 2 – As Per TEST1 plus different AET GT30 Turbo, uprated fuel system and remapping – Road Test

This part is going to be short and sweet.... why?

Things are starting to get stupid now on the road with this kind of power. I am sure people will think that "you can never have enough power" and "my next conversion needs to be 500bhp". Let me tell you something, if you have ever driven a true 500bhp modified Subaru on the road you may change your mind somewhat to what your requirements are!

This car is now so quick on the road it is now becoming unmanageable when giving it large!

Full concentration is required for anything but pootling around town (that I hasten to add is abolsutely fine and driveable), but once you give the loud pedal some excercise you really need to be holding on.

Completing acceleration runs through a gear soon has you backing off. Whatever speeds you are used to entering a corner, with the same level of accelerator pedal you will be doing a lot more speed with this kind of power.... it commands respect!

As ever the engine sounded sweet, not like you would expect at this power level..... development and methods have come a long way over the past few years.

Any gear and any speed..... this car now launches you forward with a ferocity that the brain (and stomach) does not really know what to make of. For 99% normal of people, driving a car like this I dare you to be gobsmacked. Forget rolling road figures, forget what has actually been done..... driving a car like this makes you realise what these vehicles are capable of.

Can you drive this car every day.... of course.

Do you need to be respectful of the right foot and what the car can do.... of course.

Will the car put a smile on your face every time you drive it.... almost definately.

FUN FUN FUN all the way!

We have not really made much out of the fuel area either to be honest, but can I please underline these figures are attained on plain old VPower!

It doesnt matter how you look at this, the power delivery attained is nothing short of brilliant, especially considering the fuel type and nature of the drop-in turbo.

TEST 2 – As Per TEST1 plus different AET GT30 Turbo, uprated fuel system and remapping – Road Test

This part is going to be short and sweet.... why?

Things are starting to get stupid now on the road with this kind of power. I am sure people will think that "you can never have enough power" and "my next conversion needs to be 500bhp". Let me tell you something, if you have ever driven a true 500bhp modified Subaru on the road you may change your mind somewhat to what your requirements are!

This car is now so quick on the road it is now becoming unmanageable when giving it large!

Full concentration is required for anything but pootling around town (that I hasten to add is abolsutely fine and driveable), but once you give the loud pedal some excercise you really need to be holding on.

Completing acceleration runs through a gear soon has you backing off. Whatever speeds you are used to entering a corner, with the same level of accelerator pedal you will be doing a lot more speed with this kind of power.... it commands respect!

As ever the engine sounded sweet, not like you would expect at this power level..... development and methods have come a long way over the past few years.

Any gear and any speed..... this car now launches you forward with a ferocity that the brain (and stomach) does not really know what to make of. For 99% normal of people, driving a car like this I dare you to be gobsmacked. Forget rolling road figures, forget what has actually been done..... driving a car like this makes you realise what these vehicles are capable of.

Can you drive this car every day.... of course.

Do you need to be respectful of the right foot and what the car can do.... of course.

Will the car put a smile on your face every time you drive it.... almost definately.

FUN FUN FUN all the way!

Last edited by ex-webby; 05 February 2008 at 11:11 PM.

#37

On-Track - Ten Of The Best 2007

Yet again time was against us and the next event for the car to compete at was Ten Of The Best!

As per 2006, the car formed part of the 200+ Club entry list.

Because of the lack of time and continued development, we were still not in a position to have a car that was going to perform to it's full potential. Rather than not attend and lose out on more valuable testing, we still went ahead and put in a public showing.

Similar to ScoobyLive we drafted in another driver (I have to admit my limitations here!). Unfortunately Simon was unable to make this event, but we were fortunate to take advantage of Iain Litchfield.

As discussed previously we knew we would have to make suspension setting changes on the day, and as such had PowerStations suspension expert, Curtis, on call during the day to advise on changes based on Iain's feedback.

After the first couple of laps around the handling circuit (sighting lap and first timed lap), Iain commented on how the car did not turn in sharp enough. After a quick call to Curtis, rebound and compression was changed all round on the AST's and Iain was back out on his 2nd timed lap. The changes reflected in Iain's time and at this point the car was in the top 5 overall (regardless of class).

Due to time running out, we only managed to complete 4 timed runs (each competitor is allowed 5). This was a great shame as Iain was just starting to get used to the car (this was only the 2nd oppourtunity he had driven this car at it's current level).

After Iain's last timed run the car achieved 10th in class and 13th overall on the handling circuit with a fastest time of 38.60s.

It is worth noting that due to Iain's lack of time in the car, he unfortunately never managed one clean start (with the car bogging down on each launch - a side affect of not being used to the twin plate clutch). Being very realistic, Iain could of reduced his times by at least .50s if he had launched well, which would of seen the car reaching a circa Top 7 place in class and a Top 9 place overall, without the need for any improvement anywhere else during the run. When all said and done the car did what it did, but we were all very happy with the results considering the not perfect set-up on the day and of course the lack of time the driver had behind the wheel.

The results were certainly enough to see the car beat six of the "Team Subaru" competitors as well as some other top competitors, such as Simon Norris in his EVO, Clive Seddon in his EVO and Adrain Smith in his Celica.

As with previous testing, the feedback was extremely useful and again the car travelled to and from the event on it's own steam.

Yet again time was against us and the next event for the car to compete at was Ten Of The Best!

As per 2006, the car formed part of the 200+ Club entry list.

Because of the lack of time and continued development, we were still not in a position to have a car that was going to perform to it's full potential. Rather than not attend and lose out on more valuable testing, we still went ahead and put in a public showing.

Similar to ScoobyLive we drafted in another driver (I have to admit my limitations here!). Unfortunately Simon was unable to make this event, but we were fortunate to take advantage of Iain Litchfield.

As discussed previously we knew we would have to make suspension setting changes on the day, and as such had PowerStations suspension expert, Curtis, on call during the day to advise on changes based on Iain's feedback.

After the first couple of laps around the handling circuit (sighting lap and first timed lap), Iain commented on how the car did not turn in sharp enough. After a quick call to Curtis, rebound and compression was changed all round on the AST's and Iain was back out on his 2nd timed lap. The changes reflected in Iain's time and at this point the car was in the top 5 overall (regardless of class).

Due to time running out, we only managed to complete 4 timed runs (each competitor is allowed 5). This was a great shame as Iain was just starting to get used to the car (this was only the 2nd oppourtunity he had driven this car at it's current level).

After Iain's last timed run the car achieved 10th in class and 13th overall on the handling circuit with a fastest time of 38.60s.

It is worth noting that due to Iain's lack of time in the car, he unfortunately never managed one clean start (with the car bogging down on each launch - a side affect of not being used to the twin plate clutch). Being very realistic, Iain could of reduced his times by at least .50s if he had launched well, which would of seen the car reaching a circa Top 7 place in class and a Top 9 place overall, without the need for any improvement anywhere else during the run. When all said and done the car did what it did, but we were all very happy with the results considering the not perfect set-up on the day and of course the lack of time the driver had behind the wheel.

The results were certainly enough to see the car beat six of the "Team Subaru" competitors as well as some other top competitors, such as Simon Norris in his EVO, Clive Seddon in his EVO and Adrain Smith in his Celica.

As with previous testing, the feedback was extremely useful and again the car travelled to and from the event on it's own steam.

Last edited by ex-webby; 05 February 2008 at 11:13 PM.

#38

TEST 3 – As Per TEST2 plus HYDRA EMS and remapping – Overview

One of the areas that we had become concerned of was that of the standard ECU and the (extra) functionality that this could provide.

Up to now the standard ECU with ECUTEK had been up to the job of delivering the desired power outputs and keeping everything on spec. However, using the combination of specific FMIC, turbo, fuel system and engine we had a number of minor issues regarding the driveability at this level. A large amount of these driveability issues were thought to stem from specifics like the fact that we were still using the original MAF, together with minor issues around the pipework for the FMIC (being rather on the large side) and 1150cc injectors.

As well as some driveability issues we also wanted various other facilities that would be either impossible or some what cumbersome using ECUTEK on the standard ECU. Couple this with the fact that most tuners prefer to move away from the standard ECU at this level of modification, especially for a vehicle that is to be more focused for competition use, just as our Spec C is.

There is a multitude of aftermarket ECU's available for the Subaru, but after careful consideration of both cost and functionality, we decided to try the HYDRA EMS sold in the UK by Tracktive Solutions!

First off, lets find out a bit more of what Tracktive Solutions are...

Tracktive Solutions - Explained

Ex-WRC technician, Richard Bulmer, created Tracktive Solutions in 2005. And the Melton-Mowbray-based fast road, track day and motorsport tuning brand is going from strength to strength, as more and more satisfied clients recognise the company’s obvious depth of talent.

Vastly experienced in all areas of mechanics/tuning/motorsport, and always different from the norm, Tracktive offers a wide range of facilities. First and foremost, they are the exclusive European distributor of the Hydra engine management systems. This “champagne ECU for beer money” stand-alone replacement engine control unit is available for a wide range of Japanese (and non-Jap) cars. It’s comparable in standard with top notch ECU systems like MoteC, Pectel and GEMS (which Richard also fits and maps, but prefers Hydra), at an affordable price. Bespoke wiring looms are also available, as well as mapped ‘Hydramist’ water injection systems, linked the Hydra ECU.

Away from the ECU mapping which Richard has become synonymous with, Tracktive also run a fully-functional workshop facility; offering everything from servicing, wheel and tyre packages, perfect wheel alignment, engine/suspension/brake/aesthetic upgrades (using innovative quality products), as well as an extensive menu of tuning packages; for all manner of Japanese (and, to a lesser extent, non-Jap) cars.

Another Tracktive specialty – making full use of Richard’s experience and ex-WRC talent – is offering bare shell re-builds, for racing or rallying.

One of the areas that we had become concerned of was that of the standard ECU and the (extra) functionality that this could provide.

Up to now the standard ECU with ECUTEK had been up to the job of delivering the desired power outputs and keeping everything on spec. However, using the combination of specific FMIC, turbo, fuel system and engine we had a number of minor issues regarding the driveability at this level. A large amount of these driveability issues were thought to stem from specifics like the fact that we were still using the original MAF, together with minor issues around the pipework for the FMIC (being rather on the large side) and 1150cc injectors.

As well as some driveability issues we also wanted various other facilities that would be either impossible or some what cumbersome using ECUTEK on the standard ECU. Couple this with the fact that most tuners prefer to move away from the standard ECU at this level of modification, especially for a vehicle that is to be more focused for competition use, just as our Spec C is.

There is a multitude of aftermarket ECU's available for the Subaru, but after careful consideration of both cost and functionality, we decided to try the HYDRA EMS sold in the UK by Tracktive Solutions!

First off, lets find out a bit more of what Tracktive Solutions are...

Tracktive Solutions - Explained

Ex-WRC technician, Richard Bulmer, created Tracktive Solutions in 2005. And the Melton-Mowbray-based fast road, track day and motorsport tuning brand is going from strength to strength, as more and more satisfied clients recognise the company’s obvious depth of talent.

Vastly experienced in all areas of mechanics/tuning/motorsport, and always different from the norm, Tracktive offers a wide range of facilities. First and foremost, they are the exclusive European distributor of the Hydra engine management systems. This “champagne ECU for beer money” stand-alone replacement engine control unit is available for a wide range of Japanese (and non-Jap) cars. It’s comparable in standard with top notch ECU systems like MoteC, Pectel and GEMS (which Richard also fits and maps, but prefers Hydra), at an affordable price. Bespoke wiring looms are also available, as well as mapped ‘Hydramist’ water injection systems, linked the Hydra ECU.

Away from the ECU mapping which Richard has become synonymous with, Tracktive also run a fully-functional workshop facility; offering everything from servicing, wheel and tyre packages, perfect wheel alignment, engine/suspension/brake/aesthetic upgrades (using innovative quality products), as well as an extensive menu of tuning packages; for all manner of Japanese (and, to a lesser extent, non-Jap) cars.

Another Tracktive specialty – making full use of Richard’s experience and ex-WRC talent – is offering bare shell re-builds, for racing or rallying.

Last edited by ex-webby; 12 February 2008 at 10:44 AM.

#39

HYDRA EMS

First and foremost, Tracktive certainly had the knowledge and experience that was a pre-requisite for any chosen ScoobyNet Project contributor and the discussion that was had between Tracktive and us about the abilities of the HYDRA were certainly ticking all the right boxs too.

So whats the deal with the HYDRA EMS?!

With Richard having spent so many years working with various forms of ECU

management and tuning in general the key points, with regards to Tracktive's

thoughts on promoting the Hydra ECU, were based on primarily the Quality of

the product, in terms of functionality, consistency and reliability, coupled with the pricing compared to similar specified systems.

The fact that this system was designed and built for road use, and has

since been utilised for more 'enthusiastic' use (1/4mile, track etc) is also a

big plus point, and some of the issues you can get with similar motorsport

systems have never come into the equation (such as cold start and idle,

lambda and knock control etc).

Prior to making any decision on the viability of the HYDRA EMS, Tracktive tested the system over an 18 month period, before they were convinced that it delivered everything it claimed to.

The HYDRA EMS offers many advanced functions not seen on other ECU's in this category. Some of the key features are:

First and foremost, Tracktive certainly had the knowledge and experience that was a pre-requisite for any chosen ScoobyNet Project contributor and the discussion that was had between Tracktive and us about the abilities of the HYDRA were certainly ticking all the right boxs too.

So whats the deal with the HYDRA EMS?!

With Richard having spent so many years working with various forms of ECU

management and tuning in general the key points, with regards to Tracktive's

thoughts on promoting the Hydra ECU, were based on primarily the Quality of

the product, in terms of functionality, consistency and reliability, coupled with the pricing compared to similar specified systems.

The fact that this system was designed and built for road use, and has

since been utilised for more 'enthusiastic' use (1/4mile, track etc) is also a

big plus point, and some of the issues you can get with similar motorsport

systems have never come into the equation (such as cold start and idle,

lambda and knock control etc).

Prior to making any decision on the viability of the HYDRA EMS, Tracktive tested the system over an 18 month period, before they were convinced that it delivered everything it claimed to.

The HYDRA EMS offers many advanced functions not seen on other ECU's in this category. Some of the key features are:

- 8 Sequential Injector (High Current) and Ignition Outputs

- 32 x 32 High resolution Fuel and Ignition tables

- Switchable Fuel and Ignition tables (32 x 32)

- 16 User Definable PWM Auxiliary Outputs

- Internal 3 bar Map Sensor (5 Bar Optional)

- Dual Knock Sensor inputs for closed loop control

- Dedicated NTK Wide band Lambda input

- Dual Closed Loop Narrow band Lambda control

- 9 Auxiliary inputs

- Variable Camshaft Control (up to 4 Cams)

- Drive By Wire Throttle (additional cost option)

- Antilag

- Launch Control

- Dedicated outputs for standard Vehicle Instruments

Last edited by ex-webby; 04 February 2008 at 09:48 PM.

#40

With the aftermarker ECU decided upon, we discussed a number of options around the extra facilities required with such an ECU as the HYDRA. The final requirement list was that of:

The fitment of the HYDRA was fairly straight forward, since a converter is available that simply mates the HYDRA to the existing OEM wiring loom. The internal MAP sensor of the HYDRA enables speed density mapping, which makes the standard MAF unit redundant. Since the MAF unit was all part of our Hyperflow Induction Kit tubing (mounted on the side), we left it in.

Much in the same way as the standard ECU was reprogrammed by ECUTEK, HYDRA has it's own propriety programming software. The HYDRA ECU is then connected to a laptop via a serial lead to enable mapping to take place. If you prefer to map the HYDRA yourself you receive the lead and programming software (with base maps) as part of the package.

Much in the same way as the standard ECU was reprogrammed by ECUTEK, HYDRA has it's own propriety programming software. The HYDRA ECU is then connected to a laptop via a serial lead to enable mapping to take place. If you prefer to map the HYDRA yourself you receive the lead and programming software (with base maps) as part of the package.

Because a new ECU is being used the mapper has to start from scratch, so Richard immediately set about this task. One of the areas that does tend to take a fair bit of time is that of cold start. This is when (for instance) you start your car up for the first time during the day, when everything is cold. This requires quite a lot of time to perfect (depending on specification of engine mods) as you only really get one or two chances each time you want to try it. Many tuners tend not to spend as much time on this (obviously this is down to cost to the customer). Of course those that run race cars do not really care about cold start issues..... the car won't stay cold for that long. Since Richard is a perfectionist and we also wanted a car that had the same characteristics as a standard engine regarding this function, we were pleased to hear that Richard would spend as much time as required to get this spot on (as he would with any car)!

We had already discussed how the mapping would take place and it was decided to split the mapping between on-road first (to get the base map sorted), then on a rolling road (to complete all the high rev range mapping) and finally back on-road to ensure everything was **** on.

- Launch Control

- Anti-Lag

- High / Low Boost Map

- Multiple Fuel Maps

The fitment of the HYDRA was fairly straight forward, since a converter is available that simply mates the HYDRA to the existing OEM wiring loom. The internal MAP sensor of the HYDRA enables speed density mapping, which makes the standard MAF unit redundant. Since the MAF unit was all part of our Hyperflow Induction Kit tubing (mounted on the side), we left it in.

Because a new ECU is being used the mapper has to start from scratch, so Richard immediately set about this task. One of the areas that does tend to take a fair bit of time is that of cold start. This is when (for instance) you start your car up for the first time during the day, when everything is cold. This requires quite a lot of time to perfect (depending on specification of engine mods) as you only really get one or two chances each time you want to try it. Many tuners tend not to spend as much time on this (obviously this is down to cost to the customer). Of course those that run race cars do not really care about cold start issues..... the car won't stay cold for that long. Since Richard is a perfectionist and we also wanted a car that had the same characteristics as a standard engine regarding this function, we were pleased to hear that Richard would spend as much time as required to get this spot on (as he would with any car)!

We had already discussed how the mapping would take place and it was decided to split the mapping between on-road first (to get the base map sorted), then on a rolling road (to complete all the high rev range mapping) and finally back on-road to ensure everything was **** on.

Last edited by ex-webby; 12 February 2008 at 10:45 AM.

#41

With the initial base map sorted by Tracktive, it was time to look at the rolling road mapping!

AET DynoPack Hub Dyno

Since AET had a new Hub Dyno installed, we thought it would be rude not to complete this stage of the mapping on AET's dyno! Because this engine had so much torque now (regardless of what this new ECU would do, it was quite a monster on the previous ECUTEK map from PowerStation), traction was a big issue. Using a Hub Dyno would specifically get round this!

Since AET had a new Hub Dyno installed, we thought it would be rude not to complete this stage of the mapping on AET's dyno! Because this engine had so much torque now (regardless of what this new ECU would do, it was quite a monster on the previous ECUTEK map from PowerStation), traction was a big issue. Using a Hub Dyno would specifically get round this!

The Dynopack system is installed in a custom built dyno room (as PowerStation) and it is a 4 wheel drive chassis dynometer capable of accurately recording power outputs upto a whopping 2000bhp! It would be nice to think we could exploit that potential, but I don't think this was going to be on cards!!

The Dynopack system is installed in a custom built dyno room (as PowerStation) and it is a 4 wheel drive chassis dynometer capable of accurately recording power outputs upto a whopping 2000bhp! It would be nice to think we could exploit that potential, but I don't think this was going to be on cards!!

As with a number of the best dyno cells in the country, the dyno cell at AET is totally enclosed and temperature controlled. The dyno cell is fed by numerous inlet and exhaust fans, ensuring that optimum temperatures are achieved, regardless of the outside temperatures (to a certain level).

We had previously used this dyno, just after TEST1, to get some form of comparison. Figures attained at this point were 393bhp / 373lbft AT THE HUBS. This certainly clarified the previous TEST1 figures attained on PowerStation's dyno (giving figures at the flywheel of 481bhp / 458lbft) based on simple multipliers.

With the car jacked up, wheels removed and connected to each dyno cell to each of the hubs, it was time for Richard to get to work!

HYDRA EMS - continued

Before we explain about the dyno session, it is worth explaining a bit more about the trip up to AET in the first instance.

Since the car was being driven up to AET (and it is a fair old jaunt from Tracktive), Richard wanted to take advantage of this road driving so he could further map the car for driveability and also let me give him some feedback. I was only too happy to oblige.

With Richard taking the passenger seat armed with his laptop and donning the det-cans, I took command of the steering wheel and loud pedal. At this stage (certainly until we had visited AET) boost was limited to 1bar and ignition was far from optimised.

Regardless of what power the car was producing, the driveability instantly felt better. It was the little things, when put together, that made the cars driveability a lot better. The throttle response was sharper (including part throttle). The initial pull from lowdown felt better. A number of other areas also felt cleaner / sharper, which I assume was down to better control of these huge 1150cc injectors we were using.

AET DynoPack Hub Dyno

As with a number of the best dyno cells in the country, the dyno cell at AET is totally enclosed and temperature controlled. The dyno cell is fed by numerous inlet and exhaust fans, ensuring that optimum temperatures are achieved, regardless of the outside temperatures (to a certain level).

We had previously used this dyno, just after TEST1, to get some form of comparison. Figures attained at this point were 393bhp / 373lbft AT THE HUBS. This certainly clarified the previous TEST1 figures attained on PowerStation's dyno (giving figures at the flywheel of 481bhp / 458lbft) based on simple multipliers.

With the car jacked up, wheels removed and connected to each dyno cell to each of the hubs, it was time for Richard to get to work!

HYDRA EMS - continued

Before we explain about the dyno session, it is worth explaining a bit more about the trip up to AET in the first instance.

Since the car was being driven up to AET (and it is a fair old jaunt from Tracktive), Richard wanted to take advantage of this road driving so he could further map the car for driveability and also let me give him some feedback. I was only too happy to oblige.

With Richard taking the passenger seat armed with his laptop and donning the det-cans, I took command of the steering wheel and loud pedal. At this stage (certainly until we had visited AET) boost was limited to 1bar and ignition was far from optimised.

Regardless of what power the car was producing, the driveability instantly felt better. It was the little things, when put together, that made the cars driveability a lot better. The throttle response was sharper (including part throttle). The initial pull from lowdown felt better. A number of other areas also felt cleaner / sharper, which I assume was down to better control of these huge 1150cc injectors we were using.

Last edited by ex-webby; 06 February 2008 at 10:31 PM.

#42

Don't get me wrong, the standard ECU driveability at this level of modification coped well, but you know when something is good but not very good.... the HYDRA seemed to be very good at bringing back the slight edge that had been lost in the driveability stakes.

Richard remarked during our initial discussions about ECU's, that above all else, the biggest overall improvement the HYDRA would give would be around the driveability. Richard explained that a number of his customers first remark about any conversion Tracktive completed with the HYDRA, was the driveability always coming foremost for positive comment. Something around "It's brilliant to have xxxbhp and still have brilliant driveability!". I have to admit that from our own experience previously and especially during this initial drive, we would certainly be another customer to add similar comments.

During the drive to AET, Richard wanted continuous feedback on how the car felt. With a constant two-way conversation, Richard continually altered the maps to reap further benefits.

Back to the rolling road session.......

With Andy Nichols of AET taking command of the dyno runs, Richard was free to program the HYDRA from the comfort of the passenger seat.

With initial runs complete and Richard happy with the datalogs, Richard went on to start the mapping process in full, first starting off with low boost. The first full throttle power runs gave Richard enough data to really get going, as was immediately noticeable via the dyno graphs. It was not long until power figures had surpassed the previous TEST1 run on this dyno. After a further period of time we were approaching 420bhp at the hubs.... I was carefully keeping note now! With lunchtime approaching, it was decided to have a break.

Upon discussing the previous couple of hours dyno time, Richard specifically remarked on how well both the engine and turbo responded to his adjustments of the HYDRA. The complete package was doing exactly what he expected to and in some areas, even more. My key question to Richard was whether this was about it or further power could be extracted.... Richard commented by saying "Yes.. more power will come, but more importantly a better spread!". Buy all accounts Richard was far from finished and had a number of areas he wanted to investigate with the maps.

With lunch over, both Richard and Andy got back in to the car and carried on. Figures kept creeping up over the next hour, as well as the overall graph becoming smoother. Finally Richard was very happy with what had been achieved and the mapping was finished.

So what did we end up with then after this dyno session?!

Richard remarked during our initial discussions about ECU's, that above all else, the biggest overall improvement the HYDRA would give would be around the driveability. Richard explained that a number of his customers first remark about any conversion Tracktive completed with the HYDRA, was the driveability always coming foremost for positive comment. Something around "It's brilliant to have xxxbhp and still have brilliant driveability!". I have to admit that from our own experience previously and especially during this initial drive, we would certainly be another customer to add similar comments.

During the drive to AET, Richard wanted continuous feedback on how the car felt. With a constant two-way conversation, Richard continually altered the maps to reap further benefits.

Back to the rolling road session.......

With Andy Nichols of AET taking command of the dyno runs, Richard was free to program the HYDRA from the comfort of the passenger seat.

With initial runs complete and Richard happy with the datalogs, Richard went on to start the mapping process in full, first starting off with low boost. The first full throttle power runs gave Richard enough data to really get going, as was immediately noticeable via the dyno graphs. It was not long until power figures had surpassed the previous TEST1 run on this dyno. After a further period of time we were approaching 420bhp at the hubs.... I was carefully keeping note now! With lunchtime approaching, it was decided to have a break.

Upon discussing the previous couple of hours dyno time, Richard specifically remarked on how well both the engine and turbo responded to his adjustments of the HYDRA. The complete package was doing exactly what he expected to and in some areas, even more. My key question to Richard was whether this was about it or further power could be extracted.... Richard commented by saying "Yes.. more power will come, but more importantly a better spread!". Buy all accounts Richard was far from finished and had a number of areas he wanted to investigate with the maps.

With lunch over, both Richard and Andy got back in to the car and carried on. Figures kept creeping up over the next hour, as well as the overall graph becoming smoother. Finally Richard was very happy with what had been achieved and the mapping was finished.

So what did we end up with then after this dyno session?!

Last edited by ex-webby; 06 February 2008 at 10:36 PM.

#43

TEST 3 – As Per TEST2 plus HYDRA EMS and remapping - Summary of Spec

Cosworth 2.5 engine

Cosworth 2.5 engine

AET Turbo

1150cc Injectors

Hyperflow Induction Kit

Hyperflow FMIC

SFS inlet hose

Miltek 3" Decat Exhaust System

HYDRA ECU

Peak Boost - 1.70bar

Fuel - VPower

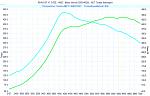

TEST 3 figure achieved was 440bhp @ the HUBS with 470 lb ft of torque @ the HUBS

TEST 3 – As Per TEST2 plus HYDRA EMS and remapping - Comments

Apart from the fact that these figures are only at the hubs (which in themselves are really good), it is very hard to compare against anything ran before. The only fair comparison is that of the previous run on this dyno (TEST1), which showed an overall increase of +47bhp / +97lbft at the hubs. How this equates to flywheel figures is anybodys guess, but using AET's own hub to flywheel estimator, the BHP at the flywheel comes out at 530bhp..... on par with what TEST2 showed with the standard ECU and ECUTEK on PowerStation's dyno. No great surprise there!

The torque front showed a massive increase. Let's see what difference was felt on the road.

TEST 3 – As Per TEST2 plus HYDRA EMS and remapping – Road Test

Since the road test was also the journey home, it was another opportunity for Richard to fettle the HYDRA!

Finally being able to unleash full boost & ignition was something worth waiting for......

It was only now that everything seemed to come together. What with the full scope of driveability polished and the full extent of the rev range mapped, the journey back to Tracktive was going to be nothing but exciting.

This was now the best this car had felt lowdown for quite sometime (remember PowerStation's comments of this car needing something more than the standard ECU, shortly after completing TEST2!?).

The mid-range surge that this car had now was also stronger than before.... that would account for the vast % increase in torque since the TEST1 dyno run at AET. Mid-range pull in 5th and 6th was now phenomenal.... even Richard remarked that it felt the same as a quick car pulls in 3rd!

Top end power felt very much the same, but this was down to the fact that any minor increase (against TEST2) would be very hard to distinguish.

Trying to stop myself performing mid-gear acceleration run's all the time, was hard to say the least.

Whilst 95% of the HYDRA mapping had now been finished (and was I glad this bit of kit had been fitted) - Richard was still adamant he could make minor tweaks to improve it further - more time was required outside of the normal mapping..... for the additional facilities we wanted!

AET Turbo

1150cc Injectors

Hyperflow Induction Kit

Hyperflow FMIC

SFS inlet hose

Miltek 3" Decat Exhaust System

HYDRA ECU

Peak Boost - 1.70bar

Fuel - VPower

TEST 3 figure achieved was 440bhp @ the HUBS with 470 lb ft of torque @ the HUBS

TEST 3 – As Per TEST2 plus HYDRA EMS and remapping - Comments

Apart from the fact that these figures are only at the hubs (which in themselves are really good), it is very hard to compare against anything ran before. The only fair comparison is that of the previous run on this dyno (TEST1), which showed an overall increase of +47bhp / +97lbft at the hubs. How this equates to flywheel figures is anybodys guess, but using AET's own hub to flywheel estimator, the BHP at the flywheel comes out at 530bhp..... on par with what TEST2 showed with the standard ECU and ECUTEK on PowerStation's dyno. No great surprise there!

The torque front showed a massive increase. Let's see what difference was felt on the road.

TEST 3 – As Per TEST2 plus HYDRA EMS and remapping – Road Test

Since the road test was also the journey home, it was another opportunity for Richard to fettle the HYDRA!

Finally being able to unleash full boost & ignition was something worth waiting for......

It was only now that everything seemed to come together. What with the full scope of driveability polished and the full extent of the rev range mapped, the journey back to Tracktive was going to be nothing but exciting.

This was now the best this car had felt lowdown for quite sometime (remember PowerStation's comments of this car needing something more than the standard ECU, shortly after completing TEST2!?).

The mid-range surge that this car had now was also stronger than before.... that would account for the vast % increase in torque since the TEST1 dyno run at AET. Mid-range pull in 5th and 6th was now phenomenal.... even Richard remarked that it felt the same as a quick car pulls in 3rd!

Top end power felt very much the same, but this was down to the fact that any minor increase (against TEST2) would be very hard to distinguish.

Trying to stop myself performing mid-gear acceleration run's all the time, was hard to say the least.

Whilst 95% of the HYDRA mapping had now been finished (and was I glad this bit of kit had been fitted) - Richard was still adamant he could make minor tweaks to improve it further - more time was required outside of the normal mapping..... for the additional facilities we wanted!

Last edited by ex-webby; 06 February 2008 at 10:39 PM.

#44

HYDRA EMS - continued

As discussed earlier, apart from better driveability we also wanted some added functionality.

Launch Control

For events that required a standing start, we wanted the ability to take some of the brain work out of the starts as well as a means to achieve better ones.

Launch Control on the HYDRA not only has the ability to enable the driver to hold the throttle flat (whilst stationary) and mantain a predetermined rev limit, but also enables the turbo to create positive boost.

Using a switch from the clutch, Richard set this up to our required rev limit, whilst enabling the turbo to produce 1bar boost from standstill.

Anti-Lag

Whilst this has no advantage on anything other than something like hillclimbing or rallying..... it sounds bloody awesome, so the big kid in me requested this function. The pop's, bang's and flames when lifting off the accelerator (whilst still maintaining boost - hence the term ANTI-lag) certainly makes you smile.

High / Low Boost Map

1.7bar High and 1bar Low - Not that the low setting would be used much, but you never know! Would be useful if we had problems with noise restrictions on some track days etc.

Switchable Fuel Map

This car had only ever been mapped for VPower, but we also wanted the facility to be able to switch to any other type of Super Unleaded (we all know how VPower can be difficult to find) and also a special map for high octane Race Fuel (this would be mapped later on in 2008).

With no hint of an issue, Richard set about sorting all these features for us.

Tracktive finished off the job very professionally, by installing a carbon plate within the upper centre console (where the stereo may be sited) to mount various switches and also have a serial link for the laptop to be plugged in to for connection to the HYDRA. Since the OEM ECU had now been removed, we had no further use for the PSi3 monitor, so the switch bank for the HYDRA took it's place.

Tracktive finished off the job very professionally, by installing a carbon plate within the upper centre console (where the stereo may be sited) to mount various switches and also have a serial link for the laptop to be plugged in to for connection to the HYDRA. Since the OEM ECU had now been removed, we had no further use for the PSi3 monitor, so the switch bank for the HYDRA took it's place.

The car, the engine...... in fact all the mods, were now finally finished!!

As discussed earlier, apart from better driveability we also wanted some added functionality.

Launch Control

For events that required a standing start, we wanted the ability to take some of the brain work out of the starts as well as a means to achieve better ones.

Launch Control on the HYDRA not only has the ability to enable the driver to hold the throttle flat (whilst stationary) and mantain a predetermined rev limit, but also enables the turbo to create positive boost.

Using a switch from the clutch, Richard set this up to our required rev limit, whilst enabling the turbo to produce 1bar boost from standstill.

Anti-Lag

Whilst this has no advantage on anything other than something like hillclimbing or rallying..... it sounds bloody awesome, so the big kid in me requested this function. The pop's, bang's and flames when lifting off the accelerator (whilst still maintaining boost - hence the term ANTI-lag) certainly makes you smile.

High / Low Boost Map

1.7bar High and 1bar Low - Not that the low setting would be used much, but you never know! Would be useful if we had problems with noise restrictions on some track days etc.

Switchable Fuel Map

This car had only ever been mapped for VPower, but we also wanted the facility to be able to switch to any other type of Super Unleaded (we all know how VPower can be difficult to find) and also a special map for high octane Race Fuel (this would be mapped later on in 2008).

With no hint of an issue, Richard set about sorting all these features for us.

The car, the engine...... in fact all the mods, were now finally finished!!

Last edited by ex-webby; 13 February 2008 at 06:26 PM.

#45

Comparison

Whilst the modification work had been done, there was just one more comparison left..... that was to re-run the Spec C on PowerStation's RR to run a direct power run comparison between TEST2 & TEST3!

I bet it doesn't matter how we test and who we use, there will always be some people who suggest that the figures that have been attained are optimistic. We have tried to substantiate the figures as best we can and have always tried to run the car at various dyno's to have a meaningful and factual comparison.

Unfortunately I am not in the position to speak for other tuners and how they can or can not reach the type of performance levels we (that's the royal WE) have reached with a 2.5l, drop-in turbo on pump fuel..... I would suggest if you have the right parts (as it would seem we have), that would go some way to meet these levels!

Anyway..... let's look at the PowerStation run with the HYDRA ECU and Tracktive Mapping.

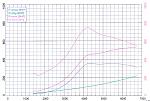

The image to the right shows the run with exactly the same parameters as TEST3, with the only difference being the run taking place on PowerStation's rolling road. This equates to the following FLYWHEEL figures (to enable a better comparison against TEST2):

The image to the right shows the run with exactly the same parameters as TEST3, with the only difference being the run taking place on PowerStation's rolling road. This equates to the following FLYWHEEL figures (to enable a better comparison against TEST2):

Figure achieved was 530.1bhp @ Flywheel with 744Nm (548.67 lb ft) of torque

+7.7bhp +25lbft (peak) over TEST2

Ok.... well I think that substantiates TEST2 figures and also the HUB DYNO readings from TEST3 (as well as we can)!!

Of course as we have said all along, peak figures (however good they are and these are GOOD!) do not mean much in isolation, so let's look at an overlay graph. The image to the right shows the original dyno run as of TEST2, against this latest dyno run (both at PowerStation) for a direct comparison.

Of course as we have said all along, peak figures (however good they are and these are GOOD!) do not mean much in isolation, so let's look at an overlay graph. The image to the right shows the original dyno run as of TEST2, against this latest dyno run (both at PowerStation) for a direct comparison.

As you can see, the higher bhp & torque lines (up to 4.5k rpm) relate to the latest run on the HYDRA. As expected, from 4.5k rpm onwards the power curves are slightly in the favour of the HYDRA (against the ECUTEK), but they are more or less on par. What the graph clearly shows is that up to 4.5k there is a vast improvement, with around (the peak torque increases aside) 45bhp and 65lbft increase through parts of the rev range!

Controlling those massive 1150cc injectors now in the car, is something that is not easily done. Couple this with the MAF unit control of the OEM ECU on ECUTEK and more complications are found. This comparison certainly does not prove anything conclusively..... but it does show you benefits have been seen! The lowdown increases shown on the recent graph certainly backs up the feeling on the road.

Whilst the modification work had been done, there was just one more comparison left..... that was to re-run the Spec C on PowerStation's RR to run a direct power run comparison between TEST2 & TEST3!

I bet it doesn't matter how we test and who we use, there will always be some people who suggest that the figures that have been attained are optimistic. We have tried to substantiate the figures as best we can and have always tried to run the car at various dyno's to have a meaningful and factual comparison.

Unfortunately I am not in the position to speak for other tuners and how they can or can not reach the type of performance levels we (that's the royal WE) have reached with a 2.5l, drop-in turbo on pump fuel..... I would suggest if you have the right parts (as it would seem we have), that would go some way to meet these levels!

Anyway..... let's look at the PowerStation run with the HYDRA ECU and Tracktive Mapping.

Figure achieved was 530.1bhp @ Flywheel with 744Nm (548.67 lb ft) of torque

+7.7bhp +25lbft (peak) over TEST2

Ok.... well I think that substantiates TEST2 figures and also the HUB DYNO readings from TEST3 (as well as we can)!!

As you can see, the higher bhp & torque lines (up to 4.5k rpm) relate to the latest run on the HYDRA. As expected, from 4.5k rpm onwards the power curves are slightly in the favour of the HYDRA (against the ECUTEK), but they are more or less on par. What the graph clearly shows is that up to 4.5k there is a vast improvement, with around (the peak torque increases aside) 45bhp and 65lbft increase through parts of the rev range!

Controlling those massive 1150cc injectors now in the car, is something that is not easily done. Couple this with the MAF unit control of the OEM ECU on ECUTEK and more complications are found. This comparison certainly does not prove anything conclusively..... but it does show you benefits have been seen! The lowdown increases shown on the recent graph certainly backs up the feeling on the road.

Last edited by ex-webby; 14 February 2008 at 08:33 PM.

#46

Conclusion

So..... another modification stage comes to and end, but what a modification stage this was!

I have been told a number of times "nothing can be taken for granted" and in part this is absolutely true. We set out many months ago to reach a target level of 500bhp using readily available parts, and whilst at times I felt we were kidding ourselves, we have undoutedly smashed past that target. This has certainly been no fluke, and whilst I fully appreciate a number of well respected tuners exist, I think above all, this modification stage has proven that a number of experienced individuals need to be involved to get the best results. Nearly everyone involved in this modification stage has gained a lot more knowledge, whether it be about a specific item used and tested or concerning new ways of looking at a problem etc.

It was not that long ago that many would state that 500bhp on pump fuel with a drop-in turbo was touch and go and unrealistic to expect. With the right parts, the right people and the right experience/knowledge..... I can state it is far from unrealistic.

To be totally honest (as we have tried to do with previous engine modification stages) we have tried to tackle a task that was not easy and certainly something that was unknown. Without a shadow of a doubt when achieving target results, it makes all the stress, time and money worth it!

Have we produced the highest powered 2.5l with a drop-in GT30 hybrid running on pump fuel with a 1.7bar peak boost level?!? Who knows.... but more importantly who cares! The main point is that we have been able to achieve our original goal of having a powerful car, with excellent driveability, and we have been able to share the story with you in the process!

To ensure we are not being out done by the many people that claim big power (but are perhaps using different fuel mixes, coupled with higher boost levels), we will certainly be getting this engine mapped (on HYDRA) with race fuel..... perhaps knocking on the door of 600bhp won't be impossible with that!!

We also have been commented on in the past as being "dyno queens"... well let's put that one to bed once and for all!!

In it's current form the ScoobyNet Project Car has ran the following during 2007:

Japfest

ScoobyLive

TOTB

2 x Track Days (each a full day)

Circa 40+ Standing Start 1/4m runs

Various other performance testing

So..... another modification stage comes to and end, but what a modification stage this was!

I have been told a number of times "nothing can be taken for granted" and in part this is absolutely true. We set out many months ago to reach a target level of 500bhp using readily available parts, and whilst at times I felt we were kidding ourselves, we have undoutedly smashed past that target. This has certainly been no fluke, and whilst I fully appreciate a number of well respected tuners exist, I think above all, this modification stage has proven that a number of experienced individuals need to be involved to get the best results. Nearly everyone involved in this modification stage has gained a lot more knowledge, whether it be about a specific item used and tested or concerning new ways of looking at a problem etc.

It was not that long ago that many would state that 500bhp on pump fuel with a drop-in turbo was touch and go and unrealistic to expect. With the right parts, the right people and the right experience/knowledge..... I can state it is far from unrealistic.

To be totally honest (as we have tried to do with previous engine modification stages) we have tried to tackle a task that was not easy and certainly something that was unknown. Without a shadow of a doubt when achieving target results, it makes all the stress, time and money worth it!

Have we produced the highest powered 2.5l with a drop-in GT30 hybrid running on pump fuel with a 1.7bar peak boost level?!? Who knows.... but more importantly who cares! The main point is that we have been able to achieve our original goal of having a powerful car, with excellent driveability, and we have been able to share the story with you in the process!

To ensure we are not being out done by the many people that claim big power (but are perhaps using different fuel mixes, coupled with higher boost levels), we will certainly be getting this engine mapped (on HYDRA) with race fuel..... perhaps knocking on the door of 600bhp won't be impossible with that!!

We also have been commented on in the past as being "dyno queens"... well let's put that one to bed once and for all!!

In it's current form the ScoobyNet Project Car has ran the following during 2007:

Japfest

ScoobyLive

TOTB

2 x Track Days (each a full day)

Circa 40+ Standing Start 1/4m runs

Various other performance testing

Last edited by ex-webby; 13 February 2008 at 08:18 PM.

#47

This engine configuration has covered approximately 5000 miles to date.

Whilst I fully accept the vehicle has had a lot of development time on the dyno, the use it has had is hardly "Sunday Driving".

As ALWAYS..... this car has been the most reliable car I have EVER had. The only issue has been that of routine maintenance / servicing... so no surprise there (or perhaps that is a surprise to some!).

Obviously we have had two different mappers map from scratch, one with ECUTEK and the other with HYDRA. One predominantly using a Rolling Road the other using an equal mix of both (and also a different dyno), with both producing very similar peak figures. Perhaps more time with ECUTEK could of yielded better results in the driveability stakes, but when all said and done the overall benefits of what HYDRA could give us was the real benefit at this modification level based on our set-up and requirements. Both PowerStation and Tracktive Solutions are true professionals..... we would certainly not hesitate to recommend either for mapping services.

So where do we go next???

Well.... we could always go and try another drop-in turbo. Yes, AET still have some more ideas of things to try! We could go rotated mount turbo.... 600bhp would then be on the cards, even on pump fuel.

Personally I think we have found a very happy (ok, very good) medium. We have very good power in a package that delivers great driveability to boot.

Believe it or not we have already discussed a Stage 4....... if that does happen it will be something slightly different again! But for now, I will just make more use of Stage 3..... I'm sure you will agree that it should keep me grinning for some time to come. But like they say.... you can never have enough power!!!

One thing you can be sure of..... any further stages of modification will surely involve the excellent supporters that have helped make Stage 3 the success that it is!

The ScoobyNet Project Spec C will be attending a number of events and track days in the future. If you see the car, please feel free to pop over for a chat.... we don't bite. You may even be offered a passenger ride (event dependant)!!!

We sincerely hope you have enjoyed reading this article as much as we have enjoyed making it.

Whilst I fully accept the vehicle has had a lot of development time on the dyno, the use it has had is hardly "Sunday Driving".