Cam belt tensioner bolt thread failure !!

#1

Scooby Regular

Thread Starter

Join Date: Feb 2012

Location: Essex

Posts: 795

Likes: 0

Received 0 Likes

on

0 Posts

Just thought I'd share with you ppl on here my fix, for what I believe is a bad design, for a component that operates under high tension and speeds

Owning my 1st scoob since feb this year , I bought this car with only 36k on the clock, thinking that there won't be much wrong with it for such low mileage car.

Service history was upto 31k , with no mention of a cam belt change, this was going to be one of the 1st jobs that i'd do on it.

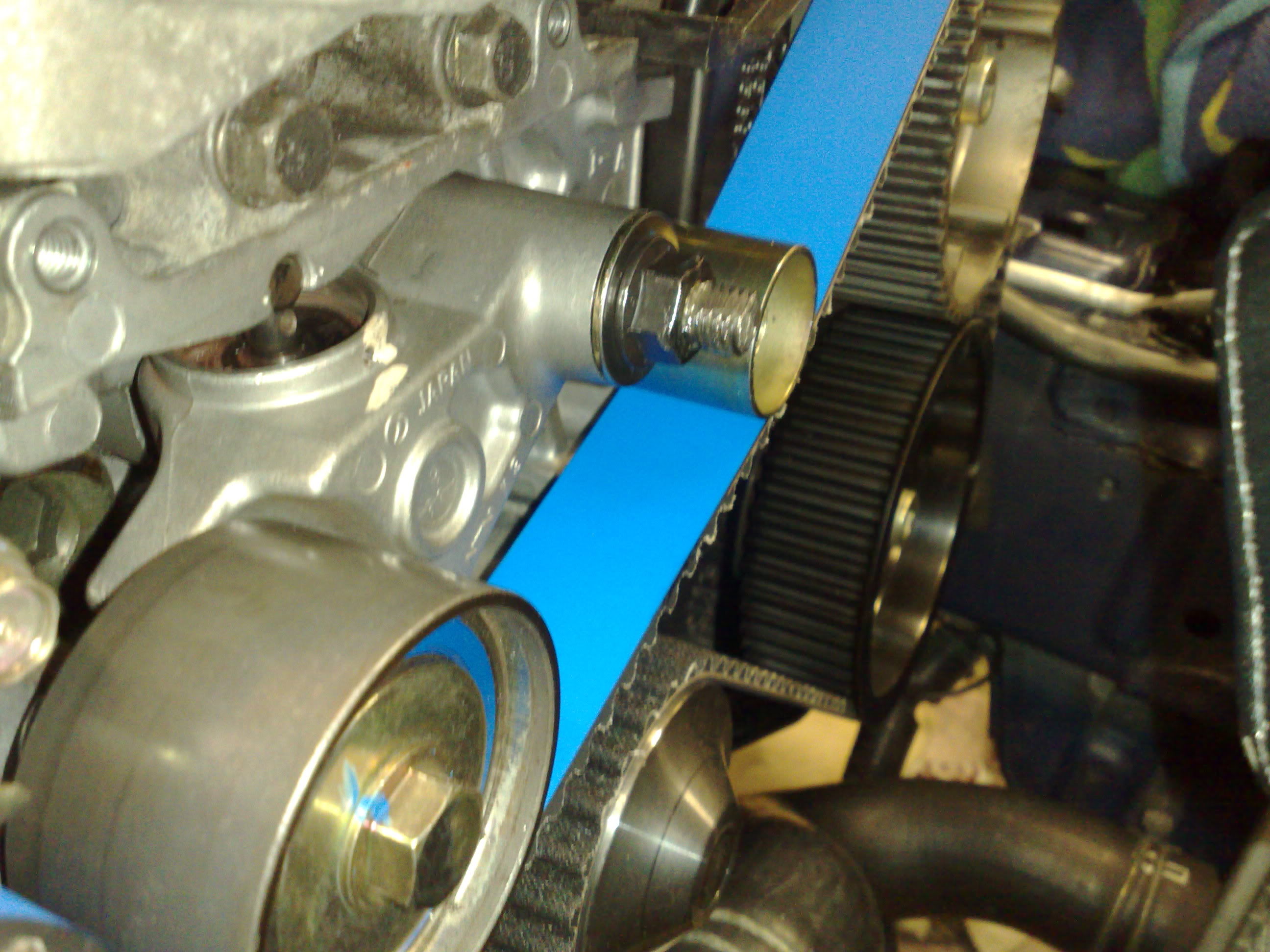

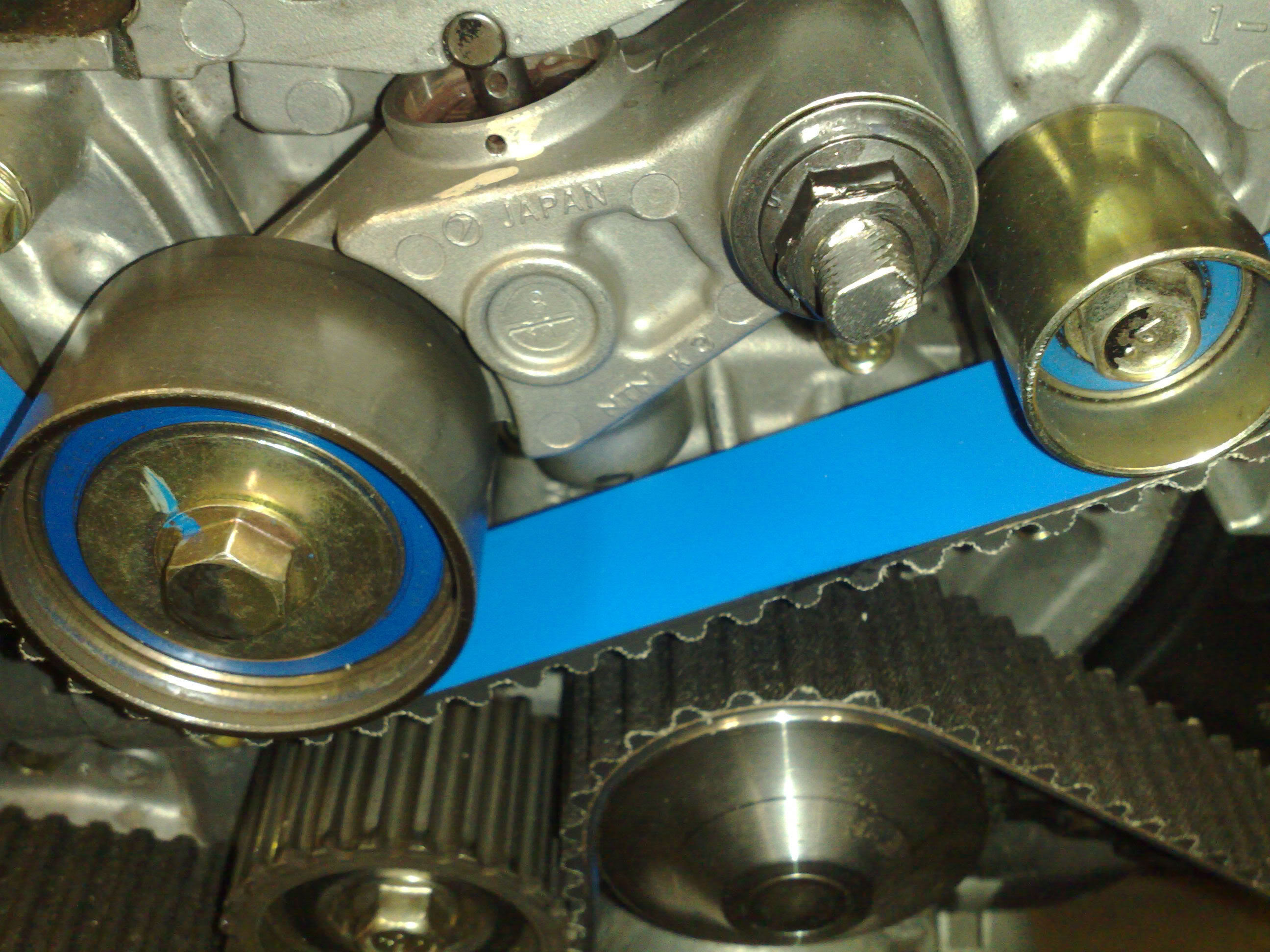

On removal of the cambelt cover , this is what I saw

With undoing the tensioner bolt, there was nothing ! No force required , I could have un-done it with my fingers. Removing the bolt I saw that the thread was covered with alloy ! The thread in the cam belt tensioner support bracket was completely gone ! well it all came out with the bolt !!

So 4 possible fixes here ..

1. Get a new bracket ( god knows what a new one would cost ) BUT you still have the same weakness.

2. Cheaper option . Helicoil the thread in the bracket with a M10 fine thread helicoil, But you'll still have the same weakness in the component !

3. Re-cut the thread in the bracket with a M12 ( standard thread) , get a M12 bolt , But the tensioner bush would need opening out from a diameter 10mm to 12mm , not something I could have done at home in a garage , this would have to be done on a lathe, But this still a weak fix

It amazed me that this cam belt tensioner , which is subjected to high amounts of force and pressure from the belt, is only held on by 15mm of M10 fine thread !!

You would have thought that for something which runs under a lot of tension, and that if it fails it's ta ta engine and a load of bent valves

I thought this would have been made a little bit stronger than this !

So we come to No 4. My fix, which I think is so much stronger than the other 3 possible fixes !

What I did was to buy a M10 x 150 long, cap head, high tensile (12.9) carbon steel bolt and 2 M10 duraloc 12.9 high tensile nuts , cost about £2

Screw 1 M10 nut onto the bolt and tighten it up BLOODY TIGHT ! ( Nut coloured in red ), hacksaw off the excess thread.

Hacksaw off the cap head !

With the tensioner bracket removed, put the bolt thru the back, slide on the tensioner arm sleeve, place a mark on bolt for where the thread has to be cut to.

Mark back about 15mm from there for the other nut and a bit extra to file a couple of flats on the end so it can be held with a spanner.

With a M10 die stock , cut the M10 thread upto the scribed mark, take it easy when cutting , half a turn at a time , then wind it back a couple of turns to remove swarf , these bolts are bloody hard !!

Once done , file the flats on end , ( about 5mm width )

Assemble the tensioner bracket with the new bolt thru the back , tighten and torque the tensioner bracket back onto the engine block.

Re-fit the tensioner arm and tighten up the other M10 duraloc nut holding the bolt with a spanner on the filed flats ! NO need for torque wrench settings here ! Tighten up until the veins in your arms start popping out !!!!

Well I think this design is rock solid !

Far much stronger than the original M10 fine thread bolt into 15mm of alloy !

Being new to sccobs is this a common failure ??

What do you guys think ?

Owning my 1st scoob since feb this year , I bought this car with only 36k on the clock, thinking that there won't be much wrong with it for such low mileage car.

Service history was upto 31k , with no mention of a cam belt change, this was going to be one of the 1st jobs that i'd do on it.

On removal of the cambelt cover , this is what I saw

With undoing the tensioner bolt, there was nothing ! No force required , I could have un-done it with my fingers. Removing the bolt I saw that the thread was covered with alloy ! The thread in the cam belt tensioner support bracket was completely gone ! well it all came out with the bolt !!

So 4 possible fixes here ..

1. Get a new bracket ( god knows what a new one would cost ) BUT you still have the same weakness.

2. Cheaper option . Helicoil the thread in the bracket with a M10 fine thread helicoil, But you'll still have the same weakness in the component !

3. Re-cut the thread in the bracket with a M12 ( standard thread) , get a M12 bolt , But the tensioner bush would need opening out from a diameter 10mm to 12mm , not something I could have done at home in a garage , this would have to be done on a lathe, But this still a weak fix

It amazed me that this cam belt tensioner , which is subjected to high amounts of force and pressure from the belt, is only held on by 15mm of M10 fine thread !!

You would have thought that for something which runs under a lot of tension, and that if it fails it's ta ta engine and a load of bent valves

I thought this would have been made a little bit stronger than this !

So we come to No 4. My fix, which I think is so much stronger than the other 3 possible fixes !

What I did was to buy a M10 x 150 long, cap head, high tensile (12.9) carbon steel bolt and 2 M10 duraloc 12.9 high tensile nuts , cost about £2

Screw 1 M10 nut onto the bolt and tighten it up BLOODY TIGHT ! ( Nut coloured in red ), hacksaw off the excess thread.

Hacksaw off the cap head !

With the tensioner bracket removed, put the bolt thru the back, slide on the tensioner arm sleeve, place a mark on bolt for where the thread has to be cut to.

Mark back about 15mm from there for the other nut and a bit extra to file a couple of flats on the end so it can be held with a spanner.

With a M10 die stock , cut the M10 thread upto the scribed mark, take it easy when cutting , half a turn at a time , then wind it back a couple of turns to remove swarf , these bolts are bloody hard !!

Once done , file the flats on end , ( about 5mm width )

Assemble the tensioner bracket with the new bolt thru the back , tighten and torque the tensioner bracket back onto the engine block.

Re-fit the tensioner arm and tighten up the other M10 duraloc nut holding the bolt with a spanner on the filed flats ! NO need for torque wrench settings here ! Tighten up until the veins in your arms start popping out !!!!

Well I think this design is rock solid !

Far much stronger than the original M10 fine thread bolt into 15mm of alloy !

Being new to sccobs is this a common failure ??

What do you guys think ?

#2

Scooby Regular

Join Date: Jan 2012

Location: Worcestershire

Posts: 170

Likes: 0

Received 0 Likes

on

0 Posts

Good Photos and description.

bad luck for you that the thread had been stripped by someone before you, im sure it wasnt a liitle radioactive japanesse person who left it like that.

sincere good fate that you didnt loose the belt during excited driving//before you did the fix. and the fix , should last ok. but i always think that the manufacturer does things for a reason , was it weak before ???? they know. I would suspect Diy madness prior to you getting the car.

now ENJOY your scoob... go safely.

bad luck for you that the thread had been stripped by someone before you, im sure it wasnt a liitle radioactive japanesse person who left it like that.

sincere good fate that you didnt loose the belt during excited driving//before you did the fix. and the fix , should last ok. but i always think that the manufacturer does things for a reason , was it weak before ???? they know. I would suspect Diy madness prior to you getting the car.

now ENJOY your scoob... go safely.

#3

Scooby Regular

Thread Starter

Join Date: Feb 2012

Location: Essex

Posts: 795

Likes: 0

Received 0 Likes

on

0 Posts

Yep i was lucky i caught it when i did mate

I don't think it was stripped by someone else, or had a failed attempt by previous 1st owner, all he could do was to check the oil , water, etc. He wasn't the type of guy to be getting his hand dirty, as he always had it serviced by subaru everytime.

The real reason why i think he sold it was that it was coming up for a major service , cam belt, aux belts, engine , gearbox and diff oil change , pads and disks , as they were the originals, he probably got a shock from the garage quote to do the work (££££££ )

)

Cam cover had never been taken off from what i could see !

If it had not been done right at time of production , i don't think it would have lasted 36k miles like that

i just thought that looking at the design , the idler does not have much support, 15mm of M10 fine thread in alloy is not very strong ! it wouldn't take much rocking force of the original M10 bolt to weaken that thread in the alloy bracket !

I was just wondering if anyone else has had a similar problem with these ?

Also to give ppl a heads up on the potential failure of this idler type

I don't think it was stripped by someone else, or had a failed attempt by previous 1st owner, all he could do was to check the oil , water, etc. He wasn't the type of guy to be getting his hand dirty, as he always had it serviced by subaru everytime.

The real reason why i think he sold it was that it was coming up for a major service , cam belt, aux belts, engine , gearbox and diff oil change , pads and disks , as they were the originals, he probably got a shock from the garage quote to do the work (££££££

)

) Cam cover had never been taken off from what i could see !

If it had not been done right at time of production , i don't think it would have lasted 36k miles like that

i just thought that looking at the design , the idler does not have much support, 15mm of M10 fine thread in alloy is not very strong ! it wouldn't take much rocking force of the original M10 bolt to weaken that thread in the alloy bracket !

I was just wondering if anyone else has had a similar problem with these ?

Also to give ppl a heads up on the potential failure of this idler type

#4

well done. I had the same problem here. Found a second hand bracket on ebay £25 but I go for this method. Much stronger. Also I am going to use thread lock, just in case...

#6

Scooby Regular

Thread Starter

Join Date: Feb 2012

Location: Essex

Posts: 795

Likes: 0

Received 0 Likes

on

0 Posts

Just to update .... This fix is still going strong

Just to update .... This fix is still going strong

#7

I had this problem before, while doing it up it threaded without much force.

Running a helicoil for now but next belt change im gonna do this.

Another Subaru fail fixed lol.

Running a helicoil for now but next belt change im gonna do this.

Another Subaru fail fixed lol.

Trending Topics

#8

Hi guys

Doing my cambelt 2nite & think I've got similar issue...

When removing tensioner bolt, and lower idler both brought load of 'thread' with it - is this what a helicoil looks like??

If so any ideas What size would I need to repair it m10 I know but what size thread- 1.0, 1.25 or 1.5....help!!

Doing my cambelt 2nite & think I've got similar issue...

When removing tensioner bolt, and lower idler both brought load of 'thread' with it - is this what a helicoil looks like??

If so any ideas What size would I need to repair it m10 I know but what size thread- 1.0, 1.25 or 1.5....help!!

Last edited by Sc00byurabus; 30 June 2014 at 08:00 PM.

#9

Sc00byurabus that is exactly like mine. Thread is M10 1.25 from what I remember. But I think best bet is to use the bolt like here. Is much stronger than a recut thread or helicoil. Bolts I got from ebay for £3 including nylon nut. High tensile M10 x 150mm you need.

Thread

Thread Starter

Forum

Replies

Last Post

Mattybr5@MB Developments

Full Cars Breaking For Spares

28

28 December 2015 11:07 PM

Mattybr5@MB Developments

Full Cars Breaking For Spares

12

18 November 2015 07:03 AM