16G to 18G Billet Wheel (Kinugawa) Conversion - Assistance Required

#1

Has anyone rebuilt themselves a TD05-18G from a Subaru TD05-16G using Kinugawa parts.

Reason I ask, is that I have just been through the process, which included :

But the Billet Wheel provided (18G 11-Bade Billet) seems to be the wrong one.

When fitted and the shaft night lightly tightened the wheel makes contact with the bearing housing/cartridge.

This wheel was provided by dealing direct with Kinugawa staff (not just picked off the website), as I was offered the 11-Blade or a 5+5 blade.

To me it looks like the profile of the base of the compressor wheel does not give enough clearance due to the larger 18G size of the wheel.

I would be interested to hear what Kinugawa part number you have fitted.

Billet Wheel fitted, showing contact with bearing housing/cartridge and shaft nut right on tip of shaft :

Original 16G wheel fitted, no contact and spins up fine :

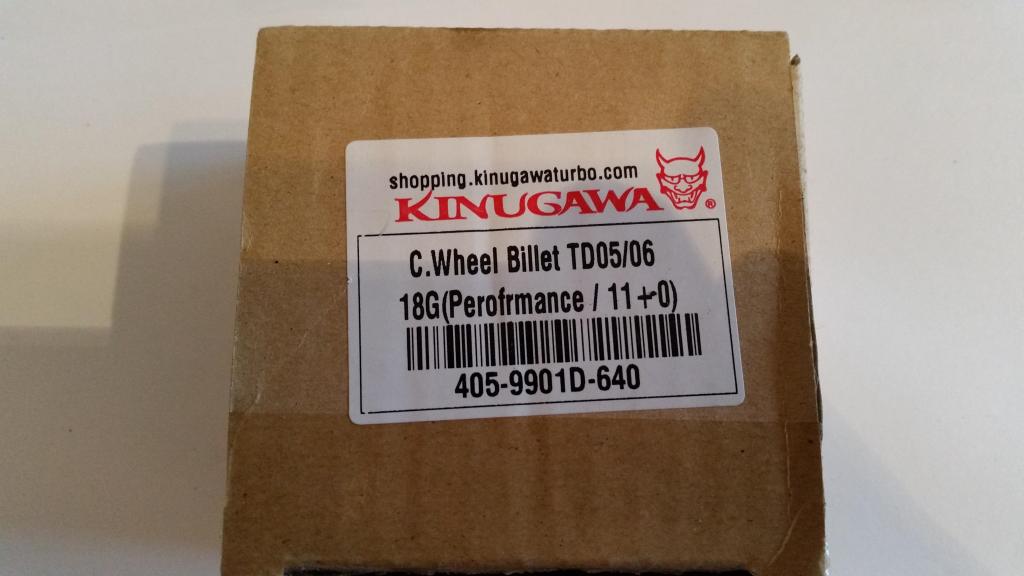

Billet Wheel P/N :

Cheers

Reason I ask, is that I have just been through the process, which included :

- Rebuild Kit (bearing/seals etc...)

- New Water line and Gasket Kit

- 18G Compressor Housing

- 18G Billet Compressor Wheel

But the Billet Wheel provided (18G 11-Bade Billet) seems to be the wrong one.

When fitted and the shaft night lightly tightened the wheel makes contact with the bearing housing/cartridge.

This wheel was provided by dealing direct with Kinugawa staff (not just picked off the website), as I was offered the 11-Blade or a 5+5 blade.

To me it looks like the profile of the base of the compressor wheel does not give enough clearance due to the larger 18G size of the wheel.

I would be interested to hear what Kinugawa part number you have fitted.

Billet Wheel fitted, showing contact with bearing housing/cartridge and shaft nut right on tip of shaft :

Original 16G wheel fitted, no contact and spins up fine :

Billet Wheel P/N :

Cheers

Last edited by Scott.T; 18 January 2015 at 05:14 PM.

#5

Scooby Regular

iTrader: (1)

Join Date: Dec 2012

Location: east sussex

Posts: 118

Likes: 0

Received 0 Likes

on

0 Posts

It is the right part you have been given the bearing/cartridge has to be machined to accept the new wheel thats all.

Hate to say it but you could of bought the bearing/cartridge from them with the new wheel all built and balanced then just fitted exhaust housing and compressor housing

Hate to say it but you could of bought the bearing/cartridge from them with the new wheel all built and balanced then just fitted exhaust housing and compressor housing

#6

It is the right part you have been given the bearing/cartridge has to be machined to accept the new wheel thats all.

Hate to say it but you could of bought the bearing/cartridge from them with the new wheel all built and balanced then just fitted exhaust housing and compressor housing

Hate to say it but you could of bought the bearing/cartridge from them with the new wheel all built and balanced then just fitted exhaust housing and compressor housing

It's been much more fun and cheaper doing it myself, and realising there's not a lot in a turbo to warrant the cost of them.

I can get it balanced for under £40.

Need to speak to Bro-in-law about his lathe and 4-jaw chuck...........

#7

Scooby Regular

iTrader: (1)

Join Date: Dec 2012

Location: east sussex

Posts: 118

Likes: 0

Received 0 Likes

on

0 Posts

Thats good then and yeah is fun doing them to be honest dont blame you for doing it yourself and even better if you no someone who can machine it. I did mine myself rather then buying a new cartridge, one thing i did on mine was opened up the exhaust gate and ported where the up pipe connects

Trending Topics

#11

Scooby Regular

iTrader: (7)

Join Date: Mar 2013

Location: Belfast

Posts: 2,999

Likes: 0

Received 0 Likes

on

0 Posts

I don't see it any more mate, my apologies. When I looked in to this it did say about machining hence why I didn't go for it. I even emailed Kinugawa to confirm, which they did. I found it on their eBay listing initially.

#13

Cheers guy's

Wheels are in motion to get it machined. Worste case scenarion is it gets dremmel'd.

I did have a good look around Kinugawa's 18G's on the website last night and found no reference to any machining requirements. Perhaps they were losing sales as a result of that statement, hence removed it.

Wheels are in motion to get it machined. Worste case scenarion is it gets dremmel'd.

I did have a good look around Kinugawa's 18G's on the website last night and found no reference to any machining requirements. Perhaps they were losing sales as a result of that statement, hence removed it.

Last edited by Scott.T; 19 January 2015 at 08:10 AM.

#18

Scooby Regular

iTrader: (5)

thanks for taking pictures. I've always wondered what actually needed machining, and it doesn't look too complicated

Is it literally a case of boring the old shoulder to 72mm?

Roughly what diameter is the cartridge btw? Just trying to figure out if my lathe is big enough

Is it literally a case of boring the old shoulder to 72mm?

Roughly what diameter is the cartridge btw? Just trying to figure out if my lathe is big enough

#20

Scooby Regular

Join Date: Dec 2013

Location: Bristol

Posts: 119

Likes: 0

Received 0 Likes

on

0 Posts

What are you doing with your old TD05 16g compressor housing? Could I do the same

with my TD04? Could I mate my TD04 turbine housing to a TD05 16g compressor to make a fast spooling hybrid?

with my TD04? Could I mate my TD04 turbine housing to a TD05 16g compressor to make a fast spooling hybrid?

#23

Scooby Regular

Join Date: Dec 2013

Location: Bristol

Posts: 119

Likes: 0

Received 0 Likes

on

0 Posts

I mean use a TD05 16g compressor housing and compressor wheel with a TD04 exhaust housing and turbine wheel.

Cheers for the link, I've just been looking at Kinugawa's ebay website to find exactly that. I wonder if that is what is used to make the hybrid turbos so many people sell. And if not, are there any other manufactures that make billet compressor wheels?

Cheers for the link, I've just been looking at Kinugawa's ebay website to find exactly that. I wonder if that is what is used to make the hybrid turbos so many people sell. And if not, are there any other manufactures that make billet compressor wheels?

#24

Scooby Regular

iTrader: (7)

Join Date: Mar 2013

Location: Belfast

Posts: 2,999

Likes: 0

Received 0 Likes

on

0 Posts

I mean use a TD05 16g compressor housing and compressor wheel with a TD04 exhaust housing and turbine wheel. Cheers for the link, I've just been looking at Kinugawa's ebay website to find exactly that. I wonder if that is what is used to make the hybrid turbos so many people sell. And if not, are there any other manufactures that make billet compressor wheels?

As far as I know that's all that's done to make a hybrid, usually a bigger/better/billet compressor wheel.

Last edited by piehole1983; 01 February 2015 at 10:16 PM.

#25

Scooby Regular

iTrader: (5)

I mean use a TD05 16g compressor housing and compressor wheel with a TD04 exhaust housing and turbine wheel.

Cheers for the link, I've just been looking at Kinugawa's ebay website to find exactly that. I wonder if that is what is used to make the hybrid turbos so many people sell. And if not, are there any other manufactures that make billet compressor wheels?

Cheers for the link, I've just been looking at Kinugawa's ebay website to find exactly that. I wonder if that is what is used to make the hybrid turbos so many people sell. And if not, are there any other manufactures that make billet compressor wheels?

Unlikely that it will work - i seem to recall the turbine shaft is a different diameter (might be wrong, though), so unless you had some kind of bushing etc turned up (and it needs to be reasonably accurate, don't forget, so not something your average joe with a lathe can turn out), it'd probably not work.

The 18/19t wheels are popular on saabs, and they seem to work well. I don't think there's any reason why they wouldn't work on a subaru td04.

#26

Took the guy less then an hour to setup and a couple of minutes to machine.

#27

If it was balanced how much material was removed and where from?

Having just bought a billet wheel for my evo3 big 16g I am curious.

Thanks

#28

#29

Did this ever happen?