Do you have to shorten a 6 speed linkage??

#1

Fitted the 6 speed box into a classic last night which was quite straight forward except for the size and weight of the thing but the linkage looks like it could do with shortening a little bit, particularly the stay bar which the lever pivots off.

Is this right? I cannot find anything when searching these forums about shortening the linkage when fitting a 6 speed into a classic.

Is this right? I cannot find anything when searching these forums about shortening the linkage when fitting a 6 speed into a classic.

#5

Former Sponsor

iTrader: (4)

Join Date: Jul 2003

Location: @Junc 12, M40 Warwicksh; 01926 614522 CV33 9PL -Use 9GX for Satnav. South Mids Alcatek ECu dealer

Posts: 6,377

Likes: 0

Received 3 Likes

on

3 Posts

Fitted the 6 speed box into a classic last night which was quite straight forward except for the size and weight of the thing but the linkage looks like it could do with shortening a little bit, particularly the stay bar which the lever pivots off.

Is this right? I cannot find anything when searching these forums about shortening the linkage when fitting a 6 speed into a classic.

Is this right? I cannot find anything when searching these forums about shortening the linkage when fitting a 6 speed into a classic.

Good luck, David APi

PS you need to bash the tunnel up over the top of the gearbox to gain some headroom and stop it hitting the floor - but that shouldn't have any effect on the shift linkage.

#6

Thanks Dave

We have a silver one ( which probably explains why it was less than £50 ).

How much does it need shortening by and do we shorten both parts by the same amount, i.e. both the linkage and the stay bar ( if thats what they're called )

Off to get a big lump hammer now to gain some clearance in the tunnel.

We have a silver one ( which probably explains why it was less than £50 ).

How much does it need shortening by and do we shorten both parts by the same amount, i.e. both the linkage and the stay bar ( if thats what they're called )

Off to get a big lump hammer now to gain some clearance in the tunnel.

#7

Former Sponsor

iTrader: (4)

Join Date: Jul 2003

Location: @Junc 12, M40 Warwicksh; 01926 614522 CV33 9PL -Use 9GX for Satnav. South Mids Alcatek ECu dealer

Posts: 6,377

Likes: 0

Received 3 Likes

on

3 Posts

Thanks Dave

We have a silver one ( which probably explains why it was less than £50 ).

How much does it need shortening by and do we shorten both parts by the same amount, i.e. both the linkage and the stay bar ( if thats what they're called )

Off to get a big lump hammer now to gain some clearance in the tunnel.

We have a silver one ( which probably explains why it was less than £50 ).

How much does it need shortening by and do we shorten both parts by the same amount, i.e. both the linkage and the stay bar ( if thats what they're called )

Off to get a big lump hammer now to gain some clearance in the tunnel.

Not easy to explain this:

Reduce the length of the steady bar and the shift bar by 17mm.

The linkage bar needs shortening from the rubber gaiter end to the middle of the bend in that shaft, to maintain the curve angle.

The steady bar can be reduced by just shortening it anyway, anyhow, anywhere. [ mmm; good title for a rock record that !! ]

Its sort of obvious when you have it in your hand once you know the length to reduce.

Good Luck - David

Trending Topics

#8

Thanks David

Thats exactly what I needed. I understand what you mean about where the linkage bar protrudes from the gaiter it is straight then bends before 'C' shaped connector, we take the 17mm out of the straight before the bend - on the gaitor side.

Wish we'd known about flattening the bit of tunnel before we'd put the box in though.......

Thats exactly what I needed. I understand what you mean about where the linkage bar protrudes from the gaiter it is straight then bends before 'C' shaped connector, we take the 17mm out of the straight before the bend - on the gaitor side.

Wish we'd known about flattening the bit of tunnel before we'd put the box in though.......

#9

Former Sponsor

iTrader: (4)

Join Date: Jul 2003

Location: @Junc 12, M40 Warwicksh; 01926 614522 CV33 9PL -Use 9GX for Satnav. South Mids Alcatek ECu dealer

Posts: 6,377

Likes: 0

Received 3 Likes

on

3 Posts

Thanks David

Thats exactly what I needed. I understand what you mean about where the linkage bar protrudes from the gaiter it is straight then bends before 'C' shaped connector, we take the 17mm out of the straight before the bend - on the gaitor side.

Wish we'd known about flattening the bit of tunnel before we'd put the box in though.......

Thats exactly what I needed. I understand what you mean about where the linkage bar protrudes from the gaiter it is straight then bends before 'C' shaped connector, we take the 17mm out of the straight before the bend - on the gaitor side.

Wish we'd known about flattening the bit of tunnel before we'd put the box in though.......

Sorry mate, my crystal ball only sees so far.

#10

Dave

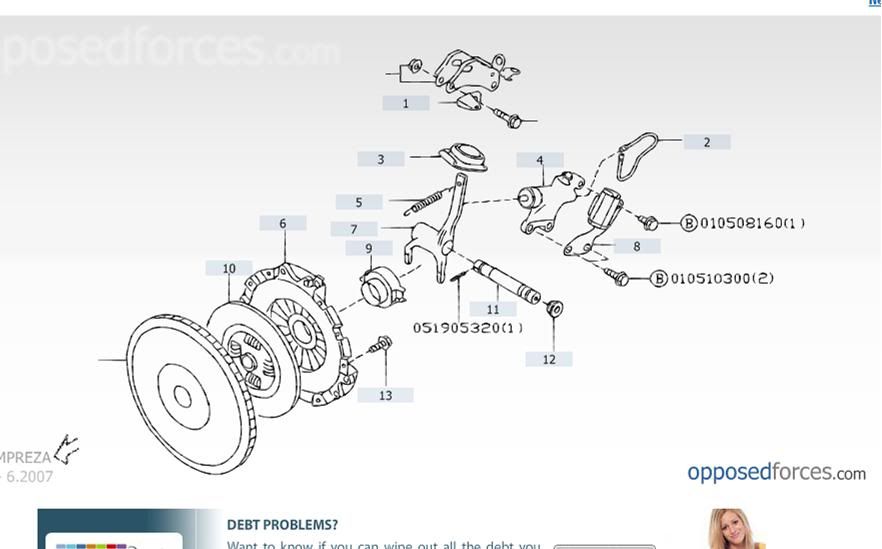

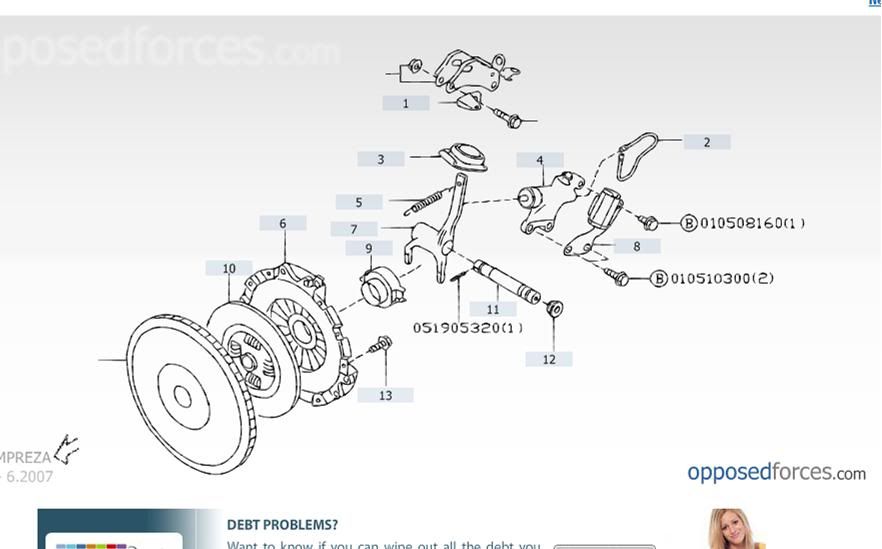

The -17mm hatchback linkage and a nice little picture for you, running your 2.5l block with forged pistons etc, etc....

Going back next month with the 6 speed.

Just one more question for you Dave, should have asked when I was down two weeks ago, but what gearbox oil do you recommend ( 6 speed non-dccd box ) I've searched on here but get a different answer on every thread and the workshop manual I've downloaded is vague too.

Thanks

Steve

#12

Former Sponsor

iTrader: (4)

Join Date: Jul 2003

Location: @Junc 12, M40 Warwicksh; 01926 614522 CV33 9PL -Use 9GX for Satnav. South Mids Alcatek ECu dealer

Posts: 6,377

Likes: 0

Received 3 Likes

on

3 Posts

Semi synth or fully 75W90 will be fine.

If you're going to beat it to death at the 'Ring then maybe Motul 75W 140 competition oil, but at £32.50 per litre you may baulk at the price. BUT it is unbeatable for performance and once bought should just be used, drained, strained and refilled. So oil for life.

David

David API

If you're going to beat it to death at the 'Ring then maybe Motul 75W 140 competition oil, but at £32.50 per litre you may baulk at the price. BUT it is unbeatable for performance and once bought should just be used, drained, strained and refilled. So oil for life.

David

David API

#13

Ok for those of you following this thread ( Banny & Dave )

Tunnel has been 'tweaked', shortened linkage is in, prop shaft is in.

But at the front end of the box something doesn't seem right, the clutch release fork and slave cylinder are in but it was a right pain to get in and the small part that it is between the slave cylinder is constantly pushing on the fork which I feel is akin to riding the clutch constantly????

On the 5 speed I seem to remember that there was a small gap between the fork and the piece of metal that pushes it and then the spring ( not shown in picture ) holds the fork against the release bearing to stop it rattling.

I want to remove the small piece of metal between slave and fork and shorten it until I have about 0.25mm between it and the fork when all assembled, is this the right course of action or is how it is now normal or is something else wrong????

Another quick one, there is no oil in the box and no starter motor at the moment so nothing has turned but when sitting in the car with the clutch depressed I can only get gears 1-4 & 6th. It will not go into 5th. Is this normal ( not quite sure how syncros work )???

Thanks again for your help so far guys.

Steve

Tunnel has been 'tweaked', shortened linkage is in, prop shaft is in.

But at the front end of the box something doesn't seem right, the clutch release fork and slave cylinder are in but it was a right pain to get in and the small part that it is between the slave cylinder is constantly pushing on the fork which I feel is akin to riding the clutch constantly????

On the 5 speed I seem to remember that there was a small gap between the fork and the piece of metal that pushes it and then the spring ( not shown in picture ) holds the fork against the release bearing to stop it rattling.

I want to remove the small piece of metal between slave and fork and shorten it until I have about 0.25mm between it and the fork when all assembled, is this the right course of action or is how it is now normal or is something else wrong????

Another quick one, there is no oil in the box and no starter motor at the moment so nothing has turned but when sitting in the car with the clutch depressed I can only get gears 1-4 & 6th. It will not go into 5th. Is this normal ( not quite sure how syncros work )???

Thanks again for your help so far guys.

Steve

Last edited by Funkierthanfunky; 02 July 2010 at 08:31 AM.

#14

Former Sponsor

iTrader: (4)

Join Date: Jul 2003

Location: @Junc 12, M40 Warwicksh; 01926 614522 CV33 9PL -Use 9GX for Satnav. South Mids Alcatek ECu dealer

Posts: 6,377

Likes: 0

Received 3 Likes

on

3 Posts

OK Is that a 6 speed clutch fork or a 5 speed one ? cos they are different and you need a 6 speed. I don't think there is any difference between the 5 speed or 6 speed slave, but we always supply a 6 speed one.

I guess you are talking about the hydraulic push rod from inside the slave. That should rest against the fork under residual pressure in the system. There may be a small gap but it isn't important. Obviously, if there is pressure forcing the push rod out then something is wrong.

I'd wait until there is oil in the box and it is rotating to worry about selecting 5th, it's probably just the synchro dog teeth not lined up and forcing it would not be good.

David

I guess you are talking about the hydraulic push rod from inside the slave. That should rest against the fork under residual pressure in the system. There may be a small gap but it isn't important. Obviously, if there is pressure forcing the push rod out then something is wrong.

I'd wait until there is oil in the box and it is rotating to worry about selecting 5th, it's probably just the synchro dog teeth not lined up and forcing it would not be good.

David

#15

6 speed fork ( I think ) it was in the box when I got it from Banny still with the pivot bolt in place.

Yes talking about the hydraulic push rod from inside the slave. I don't think there is any pressure forcing the rod out it is in it's most retracted position i.e. shortest as far as I can make out.

Steve

Yes talking about the hydraulic push rod from inside the slave. I don't think there is any pressure forcing the rod out it is in it's most retracted position i.e. shortest as far as I can make out.

Steve

#16

Scooby Regular

iTrader: (16)

Join Date: Jan 2010

Location: In Paradise

Posts: 3,097

Likes: 0

Received 0 Likes

on

0 Posts

I feel for you dude, i also have just fitted a 6 speed in to my wrx bugeye, and if its not one thing, its another. I suppose that is why we have people like Bill @ Greers and David @ Api. Good luck :-)

Last edited by EH52WRX; 02 July 2010 at 10:46 AM.

#17

Former Sponsor

iTrader: (4)

Join Date: Jul 2003

Location: @Junc 12, M40 Warwicksh; 01926 614522 CV33 9PL -Use 9GX for Satnav. South Mids Alcatek ECu dealer

Posts: 6,377

Likes: 0

Received 3 Likes

on

3 Posts

Ok for those of you following this thread ( Banny & Dave )

Tunnel has been 'tweaked', shortened linkage is in, prop shaft is in.

But at the front end of the box something doesn't seem right, the clutch release fork and slave cylinder are in but it was a right pain to get in and the small part that it is between the slave cylinder is constantly pushing on the fork which I feel is akin to riding the clutch constantly????

On the 5 speed I seem to remember that there was a small gap between the fork and the piece of metal that pushes it and then the spring ( not shown in picture ) holds the fork against the release bearing to stop it rattling.

I want to remove the small piece of metal between slave and fork and shorten it until I have about 0.25mm between it and the fork when all assembled, is this the right course of action or is how it is now normal or is something else wrong????

Another quick one, there is no oil in the box and no starter motor at the moment so nothing has turned but when sitting in the car with the clutch depressed I can only get gears 1-4 & 6th. It will not go into 5th. Is this normal ( not quite sure how syncros work )???

Thanks again for your help so far guys.

Steve

Tunnel has been 'tweaked', shortened linkage is in, prop shaft is in.

But at the front end of the box something doesn't seem right, the clutch release fork and slave cylinder are in but it was a right pain to get in and the small part that it is between the slave cylinder is constantly pushing on the fork which I feel is akin to riding the clutch constantly????

On the 5 speed I seem to remember that there was a small gap between the fork and the piece of metal that pushes it and then the spring ( not shown in picture ) holds the fork against the release bearing to stop it rattling.

I want to remove the small piece of metal between slave and fork and shorten it until I have about 0.25mm between it and the fork when all assembled, is this the right course of action or is how it is now normal or is something else wrong????

Another quick one, there is no oil in the box and no starter motor at the moment so nothing has turned but when sitting in the car with the clutch depressed I can only get gears 1-4 & 6th. It will not go into 5th. Is this normal ( not quite sure how syncros work )???

Thanks again for your help so far guys.

Steve

lt isn't a 6 speed one, that'll be your problem.

Six speed is straight without the dogleg. The one you have is an early car one as far as we can tell from the pics.

David

#18

Thanks Dave

Which means we need to find a six speed fork and then remove, prop, linkage, gearbox etc to take out the 5 speed one and fit the six speed one which should hopefully look like the item 7 in the picture below

Which means we need to find a six speed fork and then remove, prop, linkage, gearbox etc to take out the 5 speed one and fit the six speed one which should hopefully look like the item 7 in the picture below

#22

Former Sponsor

iTrader: (4)

Join Date: Jul 2003

Location: @Junc 12, M40 Warwicksh; 01926 614522 CV33 9PL -Use 9GX for Satnav. South Mids Alcatek ECu dealer

Posts: 6,377

Likes: 0

Received 3 Likes

on

3 Posts

Let's hope that is the end of the grief then.

It's usually easier with a 6 speed to take out the long studs at the bottom of the bell housing completely it allows more ' wiggle ' room

David

It's usually easier with a 6 speed to take out the long studs at the bottom of the bell housing completely it allows more ' wiggle ' room

David

#24

Hmmmm. Another problem, have got the correct ( hopefully correct ) 6 speed clutch fork in place now and the slave cylinder does not line up correctly.

If you look in the picture below the pin which pushes on the fork is pointing down at a very steep angle and just doesn't look right.

Again same as before the two bolts that hold the slave cylinder in place do not line up and if we force it in there is pressure oin the fork all the time.

So... we got a six speed slave cylinder. But this has exactly the same problem.

If you look in the picture below the pin which pushes on the fork is pointing down at a very steep angle and just doesn't look right.

Again same as before the two bolts that hold the slave cylinder in place do not line up and if we force it in there is pressure oin the fork all the time.

So... we got a six speed slave cylinder. But this has exactly the same problem.

#25

The saga continues, its up and running all connected and all seems ok until.....

You press the clutch

When the pedal gets about half way through its travel there is a metal on metal sound from within the bellhousing!!!!

The clutch seems to disengage about half way through the pedal travel but if you push the clutch to the floor it makes a really bad noise.

How many different types of clutch fork are there?? Could we have the wrong one in??

We now have three different clutch forks the one out of our 5 speed, the one that came with the 6 speed box, both with doglegs in them and one straight one purchased from Subaru ( see pic above )

Anyone know where we go from here, three weeks and 4 days until the Nurburgring!!!!

You press the clutch

When the pedal gets about half way through its travel there is a metal on metal sound from within the bellhousing!!!!

The clutch seems to disengage about half way through the pedal travel but if you push the clutch to the floor it makes a really bad noise.

How many different types of clutch fork are there?? Could we have the wrong one in??

We now have three different clutch forks the one out of our 5 speed, the one that came with the 6 speed box, both with doglegs in them and one straight one purchased from Subaru ( see pic above )

Anyone know where we go from here, three weeks and 4 days until the Nurburgring!!!!

#26

Just to clarify this.

The metal on metal horrible noise only happens when the engine is running and the clutch is pressed further than half way down.

In my opinion we either have the wrong clutch fork, or the wrong slave cylinder or both.

Changing the clutch fork is not a problem it only involves removing the whole gearbox ( again!! ) fitting the new fork and reassembling everything, which we can do in a couple of hours now.

Also changing the slave is not a problem.

But what ones do we need?????

We just purchased a 6 speed slave at £80 from ebay which appears identical in size to our 5 speed one although it does have a little reservoir thing on the side and we have also purchased what appears to be the correct fork from Subaru for £70 so we are £150 down and no further forward.

Can anyone shed any light on this??

The metal on metal horrible noise only happens when the engine is running and the clutch is pressed further than half way down.

In my opinion we either have the wrong clutch fork, or the wrong slave cylinder or both.

Changing the clutch fork is not a problem it only involves removing the whole gearbox ( again!! ) fitting the new fork and reassembling everything, which we can do in a couple of hours now.

Also changing the slave is not a problem.

But what ones do we need?????

We just purchased a 6 speed slave at £80 from ebay which appears identical in size to our 5 speed one although it does have a little reservoir thing on the side and we have also purchased what appears to be the correct fork from Subaru for £70 so we are £150 down and no further forward.

Can anyone shed any light on this??

#27

Looks like we've sorted it.

Took everything out last night ( 1hr 15min to get the 6 speed box out not too shabby )

And although we couldn't see anything obviously wrong or any witness marks on anything there was a slight mark on the clutch fork but we couldn't put it down to anything.

So, we reassembled and were very, very careful with the location and positioning of the clutch fork.

And it works!! The clutch fork now sits in a much better poistion and isn't jammed in place like before, it would seem that we some how mananged to assemble it with the clutch fork in the wrong position but we're not completely sure how as the pin it pivots on when straight in and out and all seemed ok.

So we now just have to put everything else back together!!!

I'd like to use this opportunity to to say a big thank you to API Dave as although we have spent quite a bit of money with him in the past he had nothing to do with the six speed except for setting the backlash on the front diff but has been very helpful and was quite happy to speak to me on the phone yesterday while I was picking his brains.

3 weeks and 2 days to Nurburgring.........

Took everything out last night ( 1hr 15min to get the 6 speed box out not too shabby )

And although we couldn't see anything obviously wrong or any witness marks on anything there was a slight mark on the clutch fork but we couldn't put it down to anything.

So, we reassembled and were very, very careful with the location and positioning of the clutch fork.

And it works!! The clutch fork now sits in a much better poistion and isn't jammed in place like before, it would seem that we some how mananged to assemble it with the clutch fork in the wrong position but we're not completely sure how as the pin it pivots on when straight in and out and all seemed ok.

So we now just have to put everything else back together!!!

I'd like to use this opportunity to to say a big thank you to API Dave as although we have spent quite a bit of money with him in the past he had nothing to do with the six speed except for setting the backlash on the front diff but has been very helpful and was quite happy to speak to me on the phone yesterday while I was picking his brains.

3 weeks and 2 days to Nurburgring.........

#28

Former Sponsor

iTrader: (4)

Join Date: Jul 2003

Location: @Junc 12, M40 Warwicksh; 01926 614522 CV33 9PL -Use 9GX for Satnav. South Mids Alcatek ECu dealer

Posts: 6,377

Likes: 0

Received 3 Likes

on

3 Posts

Looks like we've sorted it.

Took everything out last night ( 1hr 15min to get the 6 speed box out not too shabby )

And although we couldn't see anything obviously wrong or any witness marks on anything there was a slight mark on the clutch fork but we couldn't put it down to anything.

So, we reassembled and were very, very careful with the location and positioning of the clutch fork.

And it works!! The clutch fork now sits in a much better poistion and isn't jammed in place like before, it would seem that we some how mananged to assemble it with the clutch fork in the wrong position but we're not completely sure how as the pin it pivots on when straight in and out and all seemed ok.

So we now just have to put everything else back together!!!

I'd like to use this opportunity to to say a big thank you to API Dave as although we have spent quite a bit of money with him in the past he had nothing to do with the six speed except for setting the backlash on the front diff but has been very helpful and was quite happy to speak to me on the phone yesterday while I was picking his brains.

3 weeks and 2 days to Nurburgring.........

Took everything out last night ( 1hr 15min to get the 6 speed box out not too shabby )

And although we couldn't see anything obviously wrong or any witness marks on anything there was a slight mark on the clutch fork but we couldn't put it down to anything.

So, we reassembled and were very, very careful with the location and positioning of the clutch fork.

And it works!! The clutch fork now sits in a much better poistion and isn't jammed in place like before, it would seem that we some how mananged to assemble it with the clutch fork in the wrong position but we're not completely sure how as the pin it pivots on when straight in and out and all seemed ok.

So we now just have to put everything else back together!!!

I'd like to use this opportunity to to say a big thank you to API Dave as although we have spent quite a bit of money with him in the past he had nothing to do with the six speed except for setting the backlash on the front diff but has been very helpful and was quite happy to speak to me on the phone yesterday while I was picking his brains.

3 weeks and 2 days to Nurburgring.........

I was running out of ideas

I was running out of ideas

David APi

Thread

Thread Starter

Forum

Replies

Last Post

Mattybr5@MB Developments

Full Cars Breaking For Spares

12

18 November 2015 07:03 AM