Front diff bearing preload+back lash?

#1

Any tips on howith to find the zero point on the front diff backlash?

I've been following the subaru service manual / googling, but I don't understand what people mean when they say "screw in retainer until you can feel the gears contacting", as unless you're literally 1cm out, the gears are meshing...

others seem to suggest screwing the bottom (crown wheel side) in until the pinion becomes hard to turn, then screwing top retainer in until it's not possible to turn the pinion at all, and then backing the crown wheel out 1.5 steps, but this sounds a bit weird as well, as "hard to turn" obviously means different things to different people

I'm resetting backlash as I'mentioned moving the pinion slightly towards the front to bring the contact pattern further towards the toes on the crown wheel.

I've been following the subaru service manual / googling, but I don't understand what people mean when they say "screw in retainer until you can feel the gears contacting", as unless you're literally 1cm out, the gears are meshing...

others seem to suggest screwing the bottom (crown wheel side) in until the pinion becomes hard to turn, then screwing top retainer in until it's not possible to turn the pinion at all, and then backing the crown wheel out 1.5 steps, but this sounds a bit weird as well, as "hard to turn" obviously means different things to different people

I'm resetting backlash as I'mentioned moving the pinion slightly towards the front to bring the contact pattern further towards the toes on the crown wheel.

#3

Updating my own post for future reference, after reading the Fuji service manual extensively and modifying the instructions to take into account lack of the 'special tools' (mainly the pinion locking tool and the crank handle).

Assuming it's all taken apart, and the bearing carriers can move freely (i.e. the o-ring has been removed), place the gearbox on its side with the diff ring gear down ("the left side" down). Note my instructions also assume that you're standing in front of the gearbox now, and that the input shaft (engine side) is to the _right_:

1. Unscrew the bearing carriers (the 'cartoon sun' looking discs) so that there's slack (probably enough to have them engaged so that 1/2 of the o-ring groove is visible).

2. Bolt case halves up (careful not to bend the shims on the pinion).

3. Using your left hand, keep turning the pinion shaft clock wise (this will be the very left most cog), slowly screw the bottom bearing carrier in (keep turning that pinion shaft also). At some point, you will feel the resistance on the pinion shaft changing. Stop turning the carrier at this point.

4. Back the carrier out slightly, and make sure the pinion spins 'freely' again (i.e. no binding anywhere).

5. Repeat steps 3 + 4 a number of times (5+) to accurately gauge where the pinion starts binding lightly, and finally leave the carrier at the point where the binding just about starts (the difference between binding and no binding is like 1/4 of an index mark on the "sun" on my gearbox).

6. Now, lets move to the other sides carrier. Keep screwing this in slowly in the same way as the bottom carrier until the pinion shaft binds (I found here the difference in feel was more pronounced. It was one index mark between no binding and almost not being able to turn the pinion by hand. Leave the carrier at the point where binding starts.

*This is the zero point*

Now, we need to move the ring gear down in the case so that there's a bit of space between the pinion gear and the ring gear. This causes 'backlash', i.e. it allows the pinion to move slightly back/forth before engaging the ring gear.

To set the backlash + bearing preload, do this:

1. Unscrew the bottom carrier by 1.5 notches (this moves the ring gear away from the pinion, hence gives backlash)

2. Screw *IN* the top carrier by 1.5 notches, and then a further 1 notch to set the bearing pre-load (i.e. in 2.5 notches in total).

(Ref FSM section 14 - case assembly)

To check the backlash, lay the case on its side, and poke a dial indicator through the drain hole and put the pickup on the ring gear (tooth side, close to the edge) so that the measurement is taken as perpendicular as possible to the ring gears direction. The dial indicator needs to be somehow mounted on an arm etc to the gearbox.

Usually you'd have a Subaru Tool now to lock the pinion to the gearbox main shaft, and you'd put the gearbox into 5th gear etc, to stop it turning. However, I found that I could clamp the pinion shaft at the end to stop it moving (using a carpenters rubberised clamp).

Anyway, once the pinion is locked up, and you have the dial indicator set up, you can rock the two drive shaft stubs back and forth (same direction on both), and the ring gear will rock "the backlash", so you'll be able to see how much the backlash is by reading the two values on the dial indicator. The backlash is the difference in values.

According to section 17 of the manual, the backlash should be 0.13 — 0.18 mm (0.0051 — 0.0071 in).

You can adjust the backlash by moving the diff carriers in / out. The bottom carrier in reduces backlash, and out increases. Each index mark changes the backlash by roughly 0.05mm / 0.002". I set mine to 0.0065, as that's what I measured it at before taking the gearbox apart (and I suspect the pinion gear "wears in" to the ring gear).

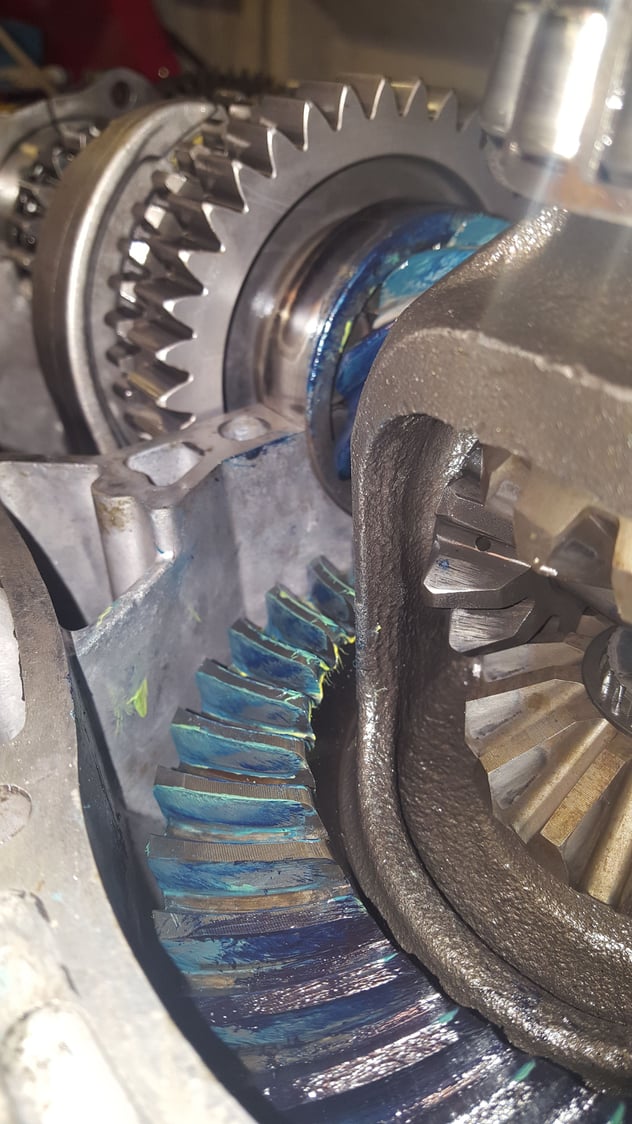

Now, you take the cases apart again, and smear either engineers blue, or yellow gear marking compound on the pinion gear, put it together again and spin the output axles. Then take the halves apart again, and see that the contact pattern between the pinion / ring gear looks correct (according to document 17, section 3 - TOOTH CONTACT OF HYPOID GEAR).

After that, smear of 3 bond, and torque cases up again.

The torque values are:

8mm bolts (12mm heads) - 18 lbsft

10mm bolts (14mm heads) - 28 lbsft

The bolts holding the pinion shaft to the case - 21 lbsft

The FSM is available here: http://www.basinger.us/Impreza/04.%2...NTIAL%20(5MT)/

Assuming it's all taken apart, and the bearing carriers can move freely (i.e. the o-ring has been removed), place the gearbox on its side with the diff ring gear down ("the left side" down). Note my instructions also assume that you're standing in front of the gearbox now, and that the input shaft (engine side) is to the _right_:

1. Unscrew the bearing carriers (the 'cartoon sun' looking discs) so that there's slack (probably enough to have them engaged so that 1/2 of the o-ring groove is visible).

2. Bolt case halves up (careful not to bend the shims on the pinion).

3. Using your left hand, keep turning the pinion shaft clock wise (this will be the very left most cog), slowly screw the bottom bearing carrier in (keep turning that pinion shaft also). At some point, you will feel the resistance on the pinion shaft changing. Stop turning the carrier at this point.

4. Back the carrier out slightly, and make sure the pinion spins 'freely' again (i.e. no binding anywhere).

5. Repeat steps 3 + 4 a number of times (5+) to accurately gauge where the pinion starts binding lightly, and finally leave the carrier at the point where the binding just about starts (the difference between binding and no binding is like 1/4 of an index mark on the "sun" on my gearbox).

6. Now, lets move to the other sides carrier. Keep screwing this in slowly in the same way as the bottom carrier until the pinion shaft binds (I found here the difference in feel was more pronounced. It was one index mark between no binding and almost not being able to turn the pinion by hand. Leave the carrier at the point where binding starts.

*This is the zero point*

Now, we need to move the ring gear down in the case so that there's a bit of space between the pinion gear and the ring gear. This causes 'backlash', i.e. it allows the pinion to move slightly back/forth before engaging the ring gear.

To set the backlash + bearing preload, do this:

1. Unscrew the bottom carrier by 1.5 notches (this moves the ring gear away from the pinion, hence gives backlash)

2. Screw *IN* the top carrier by 1.5 notches, and then a further 1 notch to set the bearing pre-load (i.e. in 2.5 notches in total).

(Ref FSM section 14 - case assembly)

To check the backlash, lay the case on its side, and poke a dial indicator through the drain hole and put the pickup on the ring gear (tooth side, close to the edge) so that the measurement is taken as perpendicular as possible to the ring gears direction. The dial indicator needs to be somehow mounted on an arm etc to the gearbox.

Usually you'd have a Subaru Tool now to lock the pinion to the gearbox main shaft, and you'd put the gearbox into 5th gear etc, to stop it turning. However, I found that I could clamp the pinion shaft at the end to stop it moving (using a carpenters rubberised clamp).

Anyway, once the pinion is locked up, and you have the dial indicator set up, you can rock the two drive shaft stubs back and forth (same direction on both), and the ring gear will rock "the backlash", so you'll be able to see how much the backlash is by reading the two values on the dial indicator. The backlash is the difference in values.

According to section 17 of the manual, the backlash should be 0.13 — 0.18 mm (0.0051 — 0.0071 in).

You can adjust the backlash by moving the diff carriers in / out. The bottom carrier in reduces backlash, and out increases. Each index mark changes the backlash by roughly 0.05mm / 0.002". I set mine to 0.0065, as that's what I measured it at before taking the gearbox apart (and I suspect the pinion gear "wears in" to the ring gear).

Now, you take the cases apart again, and smear either engineers blue, or yellow gear marking compound on the pinion gear, put it together again and spin the output axles. Then take the halves apart again, and see that the contact pattern between the pinion / ring gear looks correct (according to document 17, section 3 - TOOTH CONTACT OF HYPOID GEAR).

After that, smear of 3 bond, and torque cases up again.

The torque values are:

8mm bolts (12mm heads) - 18 lbsft

10mm bolts (14mm heads) - 28 lbsft

The bolts holding the pinion shaft to the case - 21 lbsft

The FSM is available here: http://www.basinger.us/Impreza/04.%2...NTIAL%20(5MT)/

#4

Also, the manual mentions a subaru tool to turn the bearing carriers.

I used an ER40 milling machine key instead (looks like a smaller version of a coil over adjusting spanner). I suspect a real coil over adjusting spanner would work even better, as I found my spanner was a little bit too small, but it's what I had to hand.

I used an ER40 milling machine key instead (looks like a smaller version of a coil over adjusting spanner). I suspect a real coil over adjusting spanner would work even better, as I found my spanner was a little bit too small, but it's what I had to hand.

The following users liked this post:

#6

Sorry to drag an old thread up, but just wanted to say thank you to Henrik for these posts and information within.

I have just rebuilt the box on our track car with ppg 3rd-4th, new synchros, bearings and seals etc... and this info has confirmed what I have done today, when shimming up the pinion shaft and setting preload/backlash on the front diff ring gear.

Good to see someone else getting stuck into the proper engineering of the Impreza! 😉👍

Kim

I have just rebuilt the box on our track car with ppg 3rd-4th, new synchros, bearings and seals etc... and this info has confirmed what I have done today, when shimming up the pinion shaft and setting preload/backlash on the front diff ring gear.

Good to see someone else getting stuck into the proper engineering of the Impreza! 😉👍

Kim