Attempting 5MT Transfer Shaft bearing replacement - Any tips??

#1

Scooby Regular

Thread Starter

I've taken tomorrow off to replace the transfer shaft bearings in my TY752VB3AA, which have started to whine according to road speed.

I've not done it before, and am fairly nervous! I'll be doing it on axle stands and using a bearing puller/press with OEM bearings.

I'm happy to remove the exhaust/gear linkage, and as I understand it, it's pretty straight-forward from there?

Are there any pitfalls to be warned about? Any tips would be great! Thanks

I've not done it before, and am fairly nervous! I'll be doing it on axle stands and using a bearing puller/press with OEM bearings.

I'm happy to remove the exhaust/gear linkage, and as I understand it, it's pretty straight-forward from there?

Are there any pitfalls to be warned about? Any tips would be great! Thanks

#2

Scooby Regular

This should give you a good idea of the procedure.......

http://legacygt.com/forums/showthrea...p-204445.html?

http://legacygt.com/forums/showthrea...p-204445.html?

#4

Scooby Regular

Download this pdf...........

http://ken-gilbert.com/wrx/mans/99-0...fferential.pdf

From (the pdf) page 43 onwards it will give you further info re: extension casing and on page 48 (document page number 49) it shows how to check/setup the clearances.

http://ken-gilbert.com/wrx/mans/99-0...fferential.pdf

From (the pdf) page 43 onwards it will give you further info re: extension casing and on page 48 (document page number 49) it shows how to check/setup the clearances.

#5

Scooby Regular

Thread Starter

Thanks - it's the potential requirement for different thickness thrust washers that is worrying me.

Does this concern me if I'm only changing: 806230130/806222060/806230150?

Does this concern me if I'm only changing: 806230130/806222060/806230150?

#6

Scooby Regular

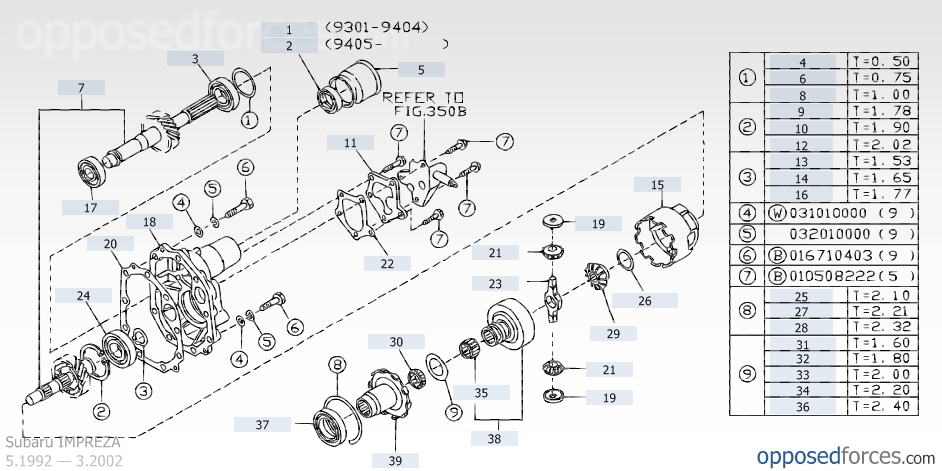

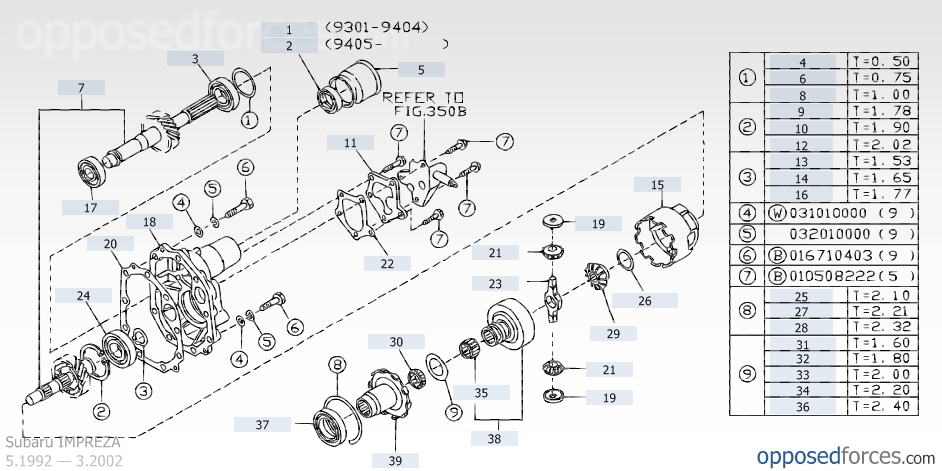

As you are replacing items 3, 17 and 24 on diagram below, it is possible that you may need to re-shim bearing 3 (shim -circled 1) and maybe also fit a different thickness of snaprings for bearing 24 (circled 2 and 3)

[img] [/img]

[/img]

Part numbers are all listed below

http://opposedforces.com/parts/impre...llustration_2/

[img]

[/img]

[/img]Part numbers are all listed below

http://opposedforces.com/parts/impre...llustration_2/

#7

Scooby Regular

Thread Starter

I feared as much.

Presuming I can't check which one I need without taking it to pieces(?), I might delay this until I've sourced all possible shims/rings.

Presuming I can't check which one I need without taking it to pieces(?), I might delay this until I've sourced all possible shims/rings.