RS3 8V: One step at a time

#1

Scooby Regular

Thread Starter

**Sorry guys - again this is being posted on other (Audi) forums, so hence the intro. Real meat will commence shortly, so apologies for the rice!"

Anyone that knows of me via my previous Subaru and A45 project threads will appreciate I like to delve that little bit deeper with my project threads, at least in respect of the kind of testing and information I like to gather and share. I aim to ensure this RS3 project thread is no different.

What I aim to do is go into detail about what’s being done, why it’s being done and be utterly truthful about the results, supported by as much evidence as possible. I’m not going to state I’m looking to reinvent the wheel, but there is no harm in aiming to make a wheel better! I’m quite excited with the potential development areas that could be investigated.

I’m a “privateer” and enthusiast, so have nothing to gain from this…… other than I absolutely love doing this kind of thing, and love to learn and experience new things. If at least one other person finds this project interesting…… that’s a mega bonus!

My previous performance car was an AMG A45, which after going through a modification project, ended up being the quickest A45 down the drag strip in the UK. Didn’t break any “real drag” records, but it achieved a decent time of 11.80s. Not bad considering it was a hatch with pretty basic levels of tuning.

So… A45 move over. Here’s the RS3!

Why did I swap out for an RS3 then?

Being totally honest….. the limited tuning available for the A45, with the Achilles heel being the transmission.

I went out and bought an RS3, pretty much fully loaded…… the kicker being that based on what has already been done with the 2.5 engine, pretty extensive levels of tuning are available. Just up my road then! Lol

Approach - Project Roadmap

Obviously I can’t do this on my own, as the amount of resources needed to do this kind of project approach justice, is more than my brain, skill and hands can cope with. So I’ll be working with a number of “professionals” along the way, but more on that once we get things underway.

The areas I would like to cover/investigate are (we’ll have to see if all these come to fruition - although certain areas have already been discussed with the individual's I’ll be working with):

Tuning Box

Secondary Decat pipes

ECU remap

Uprated plugs

Look at intercooler and inlet efficiencies at this level, look at testing upgrades if warranted

Turbo (along with remap and again looking at intercooler and inlet efficiencies).

End target is at least 500bhp - ideally looking to get in the 10’s down the strip, but this will probably need quite a bit more than 500bhp - we’ll see how this all goes.

This is all very very high level, but gives an idea of the kind of steps I’ll be looking to take. Depending upon how the car reacts, I may look at chassis / suspension / braking mods. I will also be undertaking some subtle styling mods... just to jazz things up a touch. Nothing too "Halfords" though.... don't worry!

So…. that’s enough of the introductory stuff.

The next update will be coming your way soon - so let the fun begin guys. First round of performance mods and testing will be starting at the end of August.

I really hope (and encourage) for you all to get stuck in and feel free to contribute to this open discussion thread.

Anyone that knows of me via my previous Subaru and A45 project threads will appreciate I like to delve that little bit deeper with my project threads, at least in respect of the kind of testing and information I like to gather and share. I aim to ensure this RS3 project thread is no different.

What I aim to do is go into detail about what’s being done, why it’s being done and be utterly truthful about the results, supported by as much evidence as possible. I’m not going to state I’m looking to reinvent the wheel, but there is no harm in aiming to make a wheel better! I’m quite excited with the potential development areas that could be investigated.

I’m a “privateer” and enthusiast, so have nothing to gain from this…… other than I absolutely love doing this kind of thing, and love to learn and experience new things. If at least one other person finds this project interesting…… that’s a mega bonus!

My previous performance car was an AMG A45, which after going through a modification project, ended up being the quickest A45 down the drag strip in the UK. Didn’t break any “real drag” records, but it achieved a decent time of 11.80s. Not bad considering it was a hatch with pretty basic levels of tuning.

So… A45 move over. Here’s the RS3!

Why did I swap out for an RS3 then?

Being totally honest….. the limited tuning available for the A45, with the Achilles heel being the transmission.

I went out and bought an RS3, pretty much fully loaded…… the kicker being that based on what has already been done with the 2.5 engine, pretty extensive levels of tuning are available. Just up my road then! Lol

Approach - Project Roadmap

Obviously I can’t do this on my own, as the amount of resources needed to do this kind of project approach justice, is more than my brain, skill and hands can cope with. So I’ll be working with a number of “professionals” along the way, but more on that once we get things underway.

The areas I would like to cover/investigate are (we’ll have to see if all these come to fruition - although certain areas have already been discussed with the individual's I’ll be working with):

Tuning Box

Secondary Decat pipes

ECU remap

Uprated plugs

Look at intercooler and inlet efficiencies at this level, look at testing upgrades if warranted

Turbo (along with remap and again looking at intercooler and inlet efficiencies).

End target is at least 500bhp - ideally looking to get in the 10’s down the strip, but this will probably need quite a bit more than 500bhp - we’ll see how this all goes.

This is all very very high level, but gives an idea of the kind of steps I’ll be looking to take. Depending upon how the car reacts, I may look at chassis / suspension / braking mods. I will also be undertaking some subtle styling mods... just to jazz things up a touch. Nothing too "Halfords" though.... don't worry!

So…. that’s enough of the introductory stuff.

The next update will be coming your way soon - so let the fun begin guys. First round of performance mods and testing will be starting at the end of August.

I really hope (and encourage) for you all to get stuck in and feel free to contribute to this open discussion thread.

#2

Scooby Regular

Thread Starter

Styling Mods

So before we delve into the performance side of things I thought I would make a start with completing a few subtle styling mods.

Whilst we all know what an 8V RS3 looks like, here are a few pictures of mine as I picked it up from Audi.

Obviously beauty is in the eye of the beholder, and the RS3 styling takes a bit of a battering from some. In my eyes (well… I do wear glasses!) the RS3 (as with the rest of the RS range, R8 to one side) is pretty much a Q car. Understated, but does what it needs to from a performance perspective.

Based on the previous performance cars I’ve owned the RS3 is quite understated…. but I like that. It’s a change for me and quite a pleasant one. However, I thought I would add a few minor changes….. perhaps not to everyone’s taste but they are what they are.

Wing Mirrors

As you can see from the pictures above, my car originally came with the standard matt silver wing mirror covers. I wanted to change these to either black or carbon. Yes, I appreciate there were other options for different colours from Audi, but this car was dealer stock, so I made do with what I had.

I managed to get some carbon ones off eBay for £100, which was cheap, but they used OEM covers and had carbon fibre layered on. I thought for £100 it was worth a punt. After a speedy delivery they turned up. The quality was very good…. I was impressed.

I had heard conflicting stories as to how you could remove the outer covers, with and without taking the whole assembly apart. After a thought process upon receiving the new ones, and seeing where all the lugs were located, I decided to have a go at removing the OEM covers WITHOUT taking the assembly apart.

The way to do this is by inserting a credit card (or equivalent) where you see in the picture below.

Once you’ve pushed the card in far enough, you’ll see that the clip in that area will release.

If you then move the card to the right of the picture, you will start to release further clips. You then need to move the card all the way to the left. Once done, you should notice the right hand side starting to come away from the mirror assembly. You can then move the card up that vertical side to further release the cover. Finally give the assembly on the right hand side a slight pull and it should really start to open up.

Now comes the bit where you need to be careful, but slightly forceful at the same time.

Whatever you do, do not pull the cover up. There is a horizontal clip at the left hand side (closest to the car), which will break off if you try to pull the cover up and off. You need to pull the cover into you from the front, gently but with a short / sharp action. It will just come off if you do this and all the clips will be retained.

Once the cover is off you’ll be left with the assembly behind the cover…… and no broken clips (if you do it correctly).

The first mirror took me about 10 minutes as I was doing everything carefully to find my way around each clip. The second mirror took me about 2 minutes. I didn’t break a clip on either OEM cover.

The next bit is really easy….. you just push the new cover on, exactly how you removed the OEM cover. It clips straight back into place.

As I said, quality is top notch and for a £100 they were very good value.

They have the desired effect, especially with the car being Daytona….. Looks quite stealth with black trim.

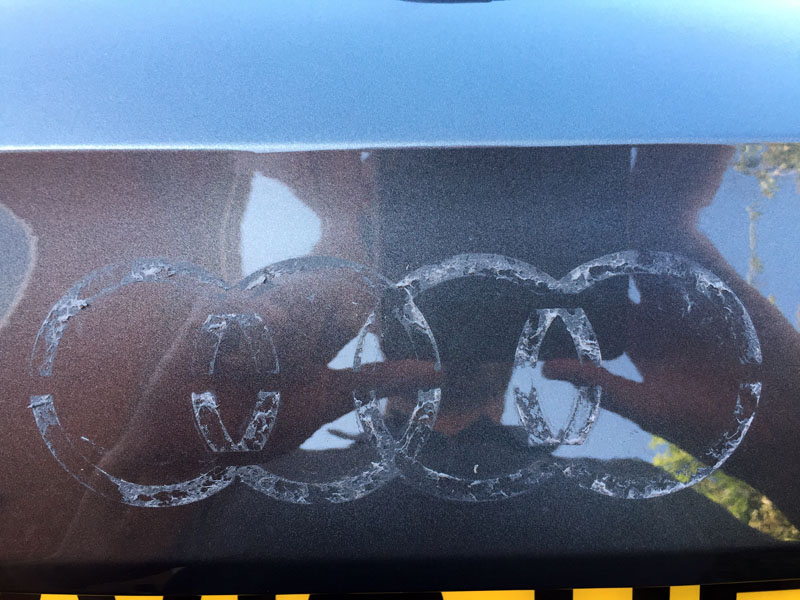

Audi Rings

You might start to see a pattern as to where I’ll be going with this car…. external styling wise.

Next up was to replace the front and rear Audi rings with a black ring set. Now, I could have tried the plasti-kote method, but I decided to opt for replacement badge sets.

Again, eBay can be your friend here. I bought this set for just under £20 for the front and rear. You need to be careful ordering the correct front badge, as I understand the 8V badges are slightly bigger than the previous cars. You may also (if you’re eagle eyed) notice the smaller rear rings are slightly smaller than the OEM ones. This isn’t an issue, but there is a difference…. just so you’re aware.

Rear Rings

I started off with replacing the rear ring set.

These are bonded on to the boot lid with adhesive, so using a hairdryer (the Mrs’ not mine as I haven't any hair!) I heated the rear badge, and then slid a credit card (same trick as with the mirror covers) between the badge and the boot lid skin to break the seal.

Making sure you keep applying heat, keep repeating this process around the whole badge. I wouldn’t recommend you start to pull the badge off straight away…. you’ll probably end up snapping it. Just take your time.

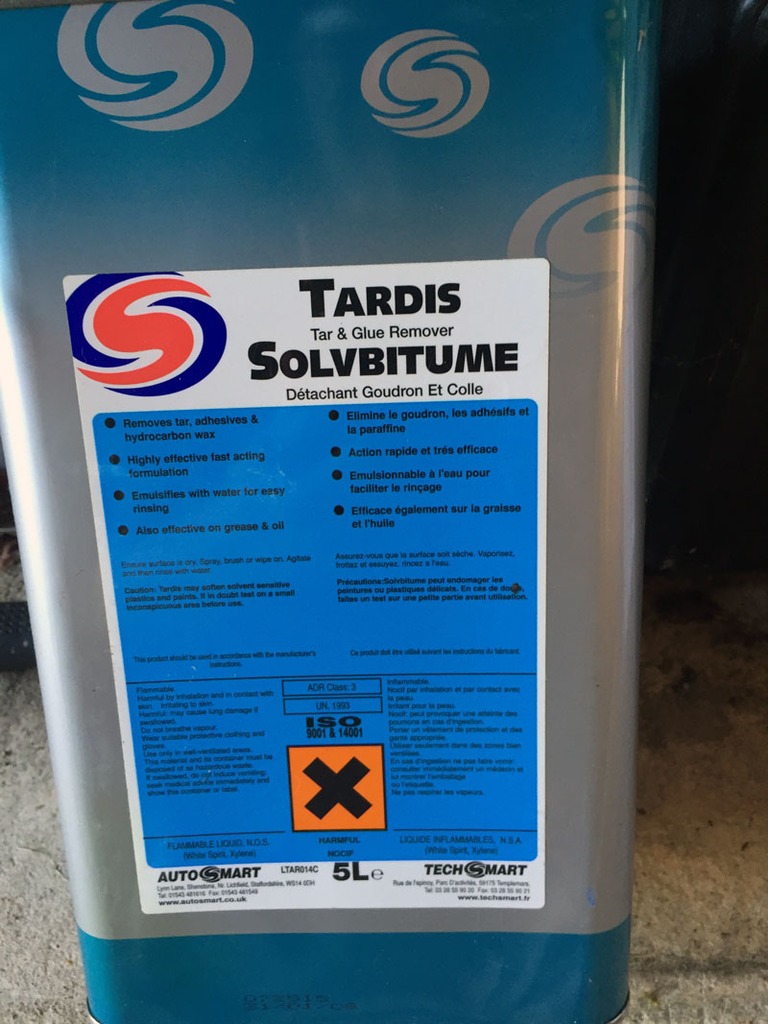

Once you’ve removed the badge you will still be left with residue from the glue.

At this point I continued to apply heat and pulled off further what I could.

With the last bits of glue left I then turned to using some glue / tar remover (TARDIS). I’ve used this for many years to remove tar from the sides of cars and glue from vinyl car stickers. This emulsifies with water, so is really easy to rinse off. You don’t want any wax or cutting agents left on the panel prior to putting your new badge on.

After liberally applying TARDIS and cleaning / rinsing the panel, it was all clear / clean and ready for the new badge.

To ensure I put the new badge on square I measured and placed a masking tape line (with a centre position) on the boot lid and offered up the new badge before final fitment.

After I was happy with the positioning I then stuck the new badge on, peeling off the backing to the new adhesive layer on the new badge. Personally I always gently heat the adhesive…. not too much, but just enough to help the bonding process.

Front Rings

Next up was the front ring set. Again I had heard conflicting stories about removing these. Some saying you needed to remove the front bumper, others saying you can reach down from the top and get to the clips and one other I saw said you could remove from the front. I chose the latter!

In my opinion I would not advise you try to remove the rings from the front (without taking the bumper off) unless you have suitable trim tools, spudgers etc. You’ll either risk snapping the oem badge or damaging the badge grill surrounds.

Using a trim tool start from the bottom. With your new badge as a guide, you’ll see exactly where the securing tabs are and this is where you need to feed the trim tool in to push the tabs back.

As you pop the bottom clips you’ll see the badge coming away from the grill.

Once you’ve released the bottom and lower side / centre side clips, then move to the top clips.

This is the first time I’ve done this and it only took me around 10 minutes. Just to prove I never broke any clips, here is the underside of the OEM badge. There was zero damage to the badge / grill surround either.

Once removed you’ll be faced with the grill ring mount, which will need a minor clean up prior to fitting the new ring set.

Mounting the new ring set is easy. Just push it on ensuring all the clips are engaged correctly.

Much like the mirrors, I really like the look of the all black trim set. Makes it look stealth, but also aggressive…. not everyone’s cup of tea I’m sure.

So for the time being that’s the first round of styling mods. I’m planning to do a few more things, but I’ll discuss this as and when I get to do them.

So before we delve into the performance side of things I thought I would make a start with completing a few subtle styling mods.

Whilst we all know what an 8V RS3 looks like, here are a few pictures of mine as I picked it up from Audi.

Obviously beauty is in the eye of the beholder, and the RS3 styling takes a bit of a battering from some. In my eyes (well… I do wear glasses!) the RS3 (as with the rest of the RS range, R8 to one side) is pretty much a Q car. Understated, but does what it needs to from a performance perspective.

Based on the previous performance cars I’ve owned the RS3 is quite understated…. but I like that. It’s a change for me and quite a pleasant one. However, I thought I would add a few minor changes….. perhaps not to everyone’s taste but they are what they are.

Wing Mirrors

As you can see from the pictures above, my car originally came with the standard matt silver wing mirror covers. I wanted to change these to either black or carbon. Yes, I appreciate there were other options for different colours from Audi, but this car was dealer stock, so I made do with what I had.

I managed to get some carbon ones off eBay for £100, which was cheap, but they used OEM covers and had carbon fibre layered on. I thought for £100 it was worth a punt. After a speedy delivery they turned up. The quality was very good…. I was impressed.

I had heard conflicting stories as to how you could remove the outer covers, with and without taking the whole assembly apart. After a thought process upon receiving the new ones, and seeing where all the lugs were located, I decided to have a go at removing the OEM covers WITHOUT taking the assembly apart.

The way to do this is by inserting a credit card (or equivalent) where you see in the picture below.

Once you’ve pushed the card in far enough, you’ll see that the clip in that area will release.

If you then move the card to the right of the picture, you will start to release further clips. You then need to move the card all the way to the left. Once done, you should notice the right hand side starting to come away from the mirror assembly. You can then move the card up that vertical side to further release the cover. Finally give the assembly on the right hand side a slight pull and it should really start to open up.

Now comes the bit where you need to be careful, but slightly forceful at the same time.

Whatever you do, do not pull the cover up. There is a horizontal clip at the left hand side (closest to the car), which will break off if you try to pull the cover up and off. You need to pull the cover into you from the front, gently but with a short / sharp action. It will just come off if you do this and all the clips will be retained.

Once the cover is off you’ll be left with the assembly behind the cover…… and no broken clips (if you do it correctly).

The first mirror took me about 10 minutes as I was doing everything carefully to find my way around each clip. The second mirror took me about 2 minutes. I didn’t break a clip on either OEM cover.

The next bit is really easy….. you just push the new cover on, exactly how you removed the OEM cover. It clips straight back into place.

As I said, quality is top notch and for a £100 they were very good value.

They have the desired effect, especially with the car being Daytona….. Looks quite stealth with black trim.

Audi Rings

You might start to see a pattern as to where I’ll be going with this car…. external styling wise.

Next up was to replace the front and rear Audi rings with a black ring set. Now, I could have tried the plasti-kote method, but I decided to opt for replacement badge sets.

Again, eBay can be your friend here. I bought this set for just under £20 for the front and rear. You need to be careful ordering the correct front badge, as I understand the 8V badges are slightly bigger than the previous cars. You may also (if you’re eagle eyed) notice the smaller rear rings are slightly smaller than the OEM ones. This isn’t an issue, but there is a difference…. just so you’re aware.

Rear Rings

I started off with replacing the rear ring set.

These are bonded on to the boot lid with adhesive, so using a hairdryer (the Mrs’ not mine as I haven't any hair!) I heated the rear badge, and then slid a credit card (same trick as with the mirror covers) between the badge and the boot lid skin to break the seal.

Making sure you keep applying heat, keep repeating this process around the whole badge. I wouldn’t recommend you start to pull the badge off straight away…. you’ll probably end up snapping it. Just take your time.

Once you’ve removed the badge you will still be left with residue from the glue.

At this point I continued to apply heat and pulled off further what I could.

With the last bits of glue left I then turned to using some glue / tar remover (TARDIS). I’ve used this for many years to remove tar from the sides of cars and glue from vinyl car stickers. This emulsifies with water, so is really easy to rinse off. You don’t want any wax or cutting agents left on the panel prior to putting your new badge on.

After liberally applying TARDIS and cleaning / rinsing the panel, it was all clear / clean and ready for the new badge.

To ensure I put the new badge on square I measured and placed a masking tape line (with a centre position) on the boot lid and offered up the new badge before final fitment.

After I was happy with the positioning I then stuck the new badge on, peeling off the backing to the new adhesive layer on the new badge. Personally I always gently heat the adhesive…. not too much, but just enough to help the bonding process.

Front Rings

Next up was the front ring set. Again I had heard conflicting stories about removing these. Some saying you needed to remove the front bumper, others saying you can reach down from the top and get to the clips and one other I saw said you could remove from the front. I chose the latter!

In my opinion I would not advise you try to remove the rings from the front (without taking the bumper off) unless you have suitable trim tools, spudgers etc. You’ll either risk snapping the oem badge or damaging the badge grill surrounds.

Using a trim tool start from the bottom. With your new badge as a guide, you’ll see exactly where the securing tabs are and this is where you need to feed the trim tool in to push the tabs back.

As you pop the bottom clips you’ll see the badge coming away from the grill.

Once you’ve released the bottom and lower side / centre side clips, then move to the top clips.

This is the first time I’ve done this and it only took me around 10 minutes. Just to prove I never broke any clips, here is the underside of the OEM badge. There was zero damage to the badge / grill surround either.

Once removed you’ll be faced with the grill ring mount, which will need a minor clean up prior to fitting the new ring set.

Mounting the new ring set is easy. Just push it on ensuring all the clips are engaged correctly.

Much like the mirrors, I really like the look of the all black trim set. Makes it look stealth, but also aggressive…. not everyone’s cup of tea I’m sure.

So for the time being that’s the first round of styling mods. I’m planning to do a few more things, but I’ll discuss this as and when I get to do them.

#4

Scooby Regular

Thread Starter

Stock Power Performance Benchmarking

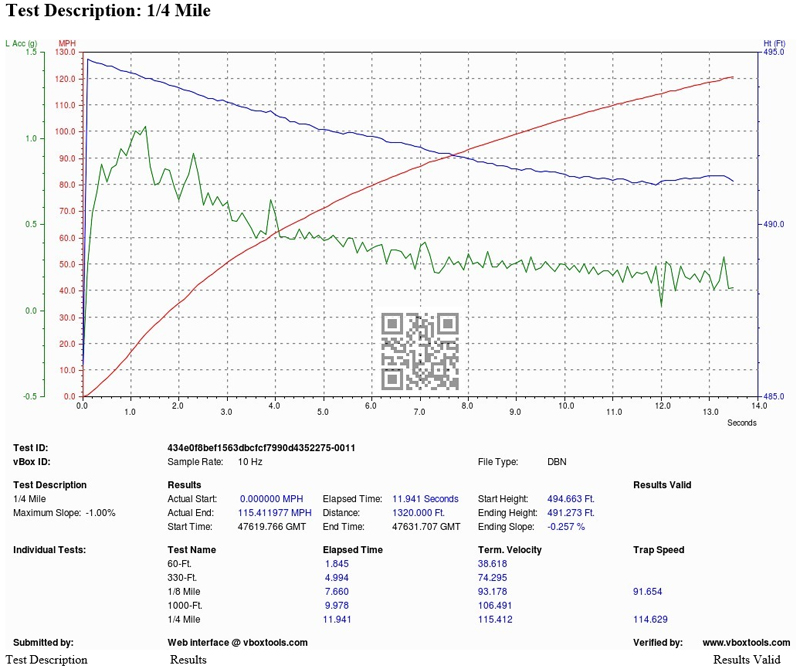

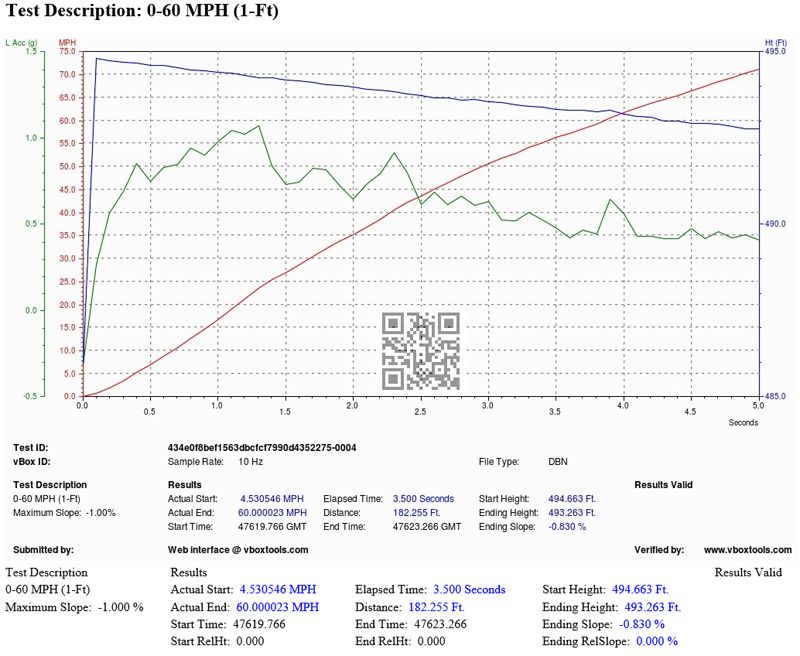

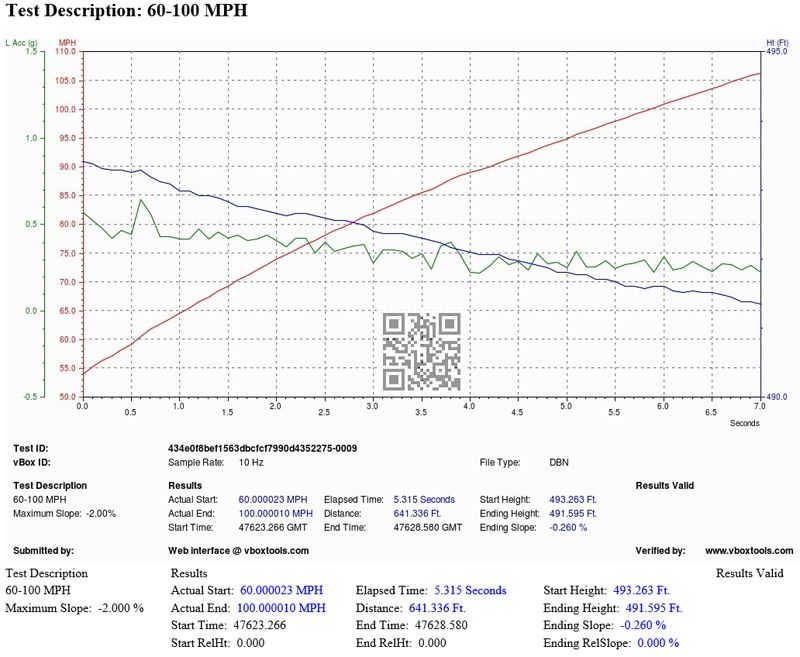

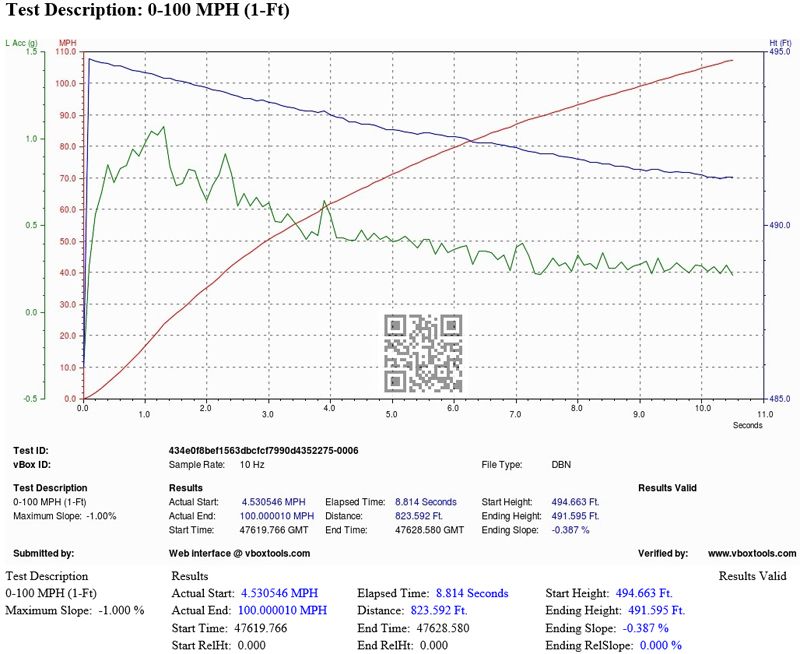

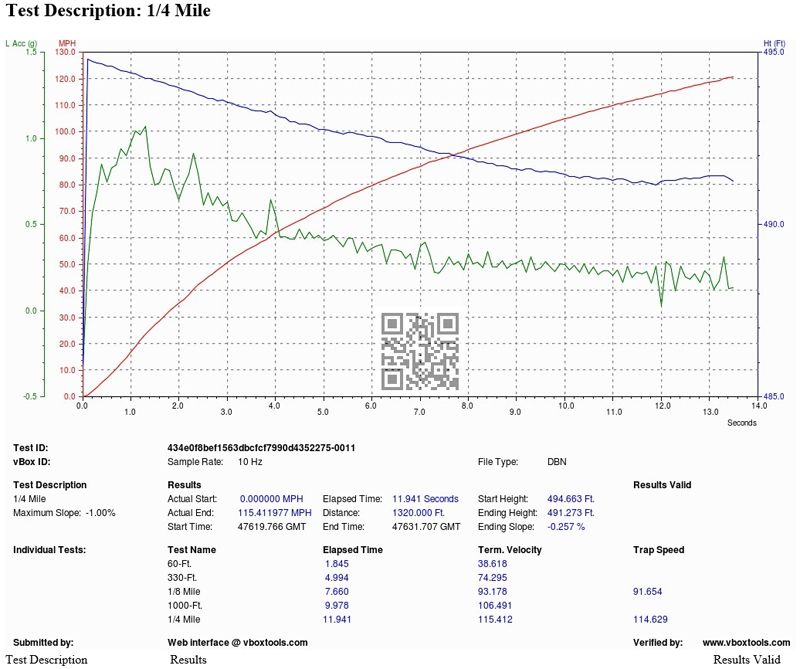

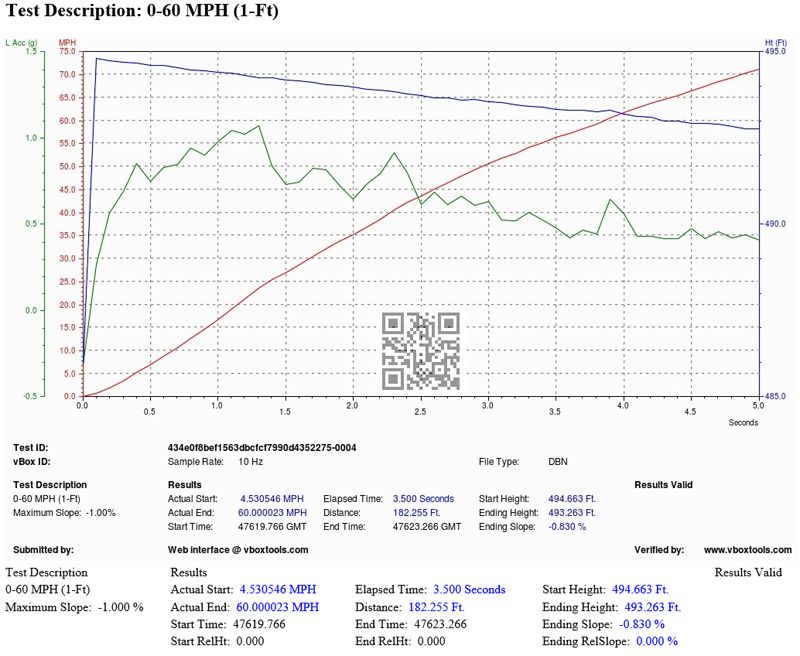

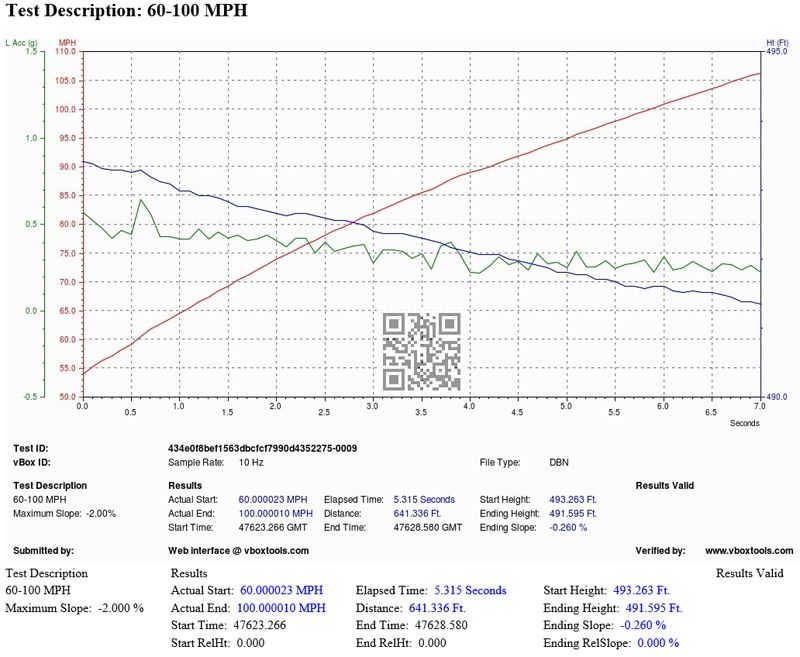

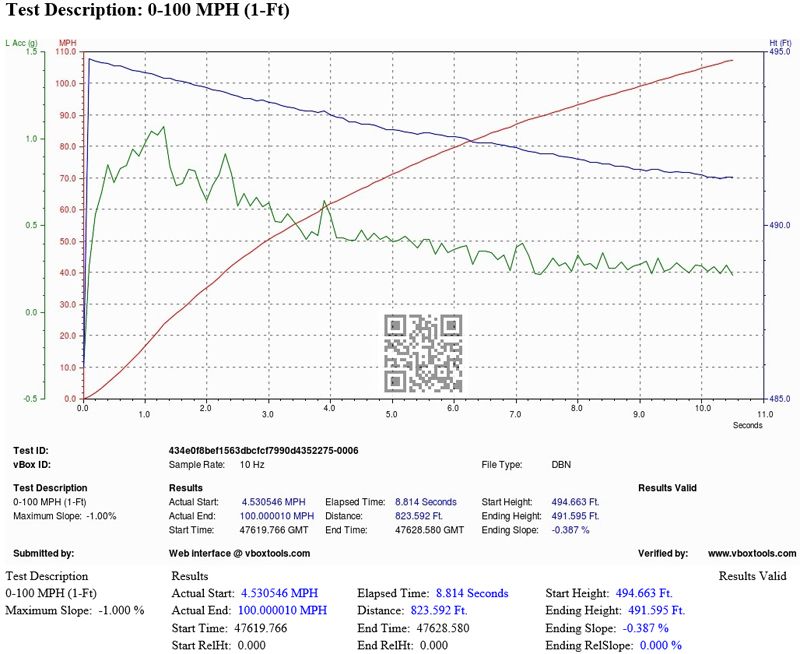

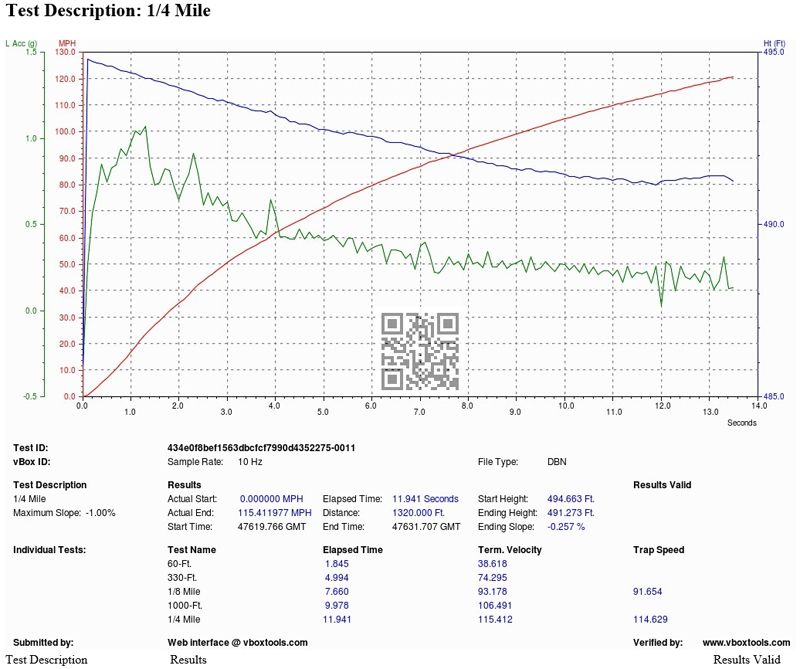

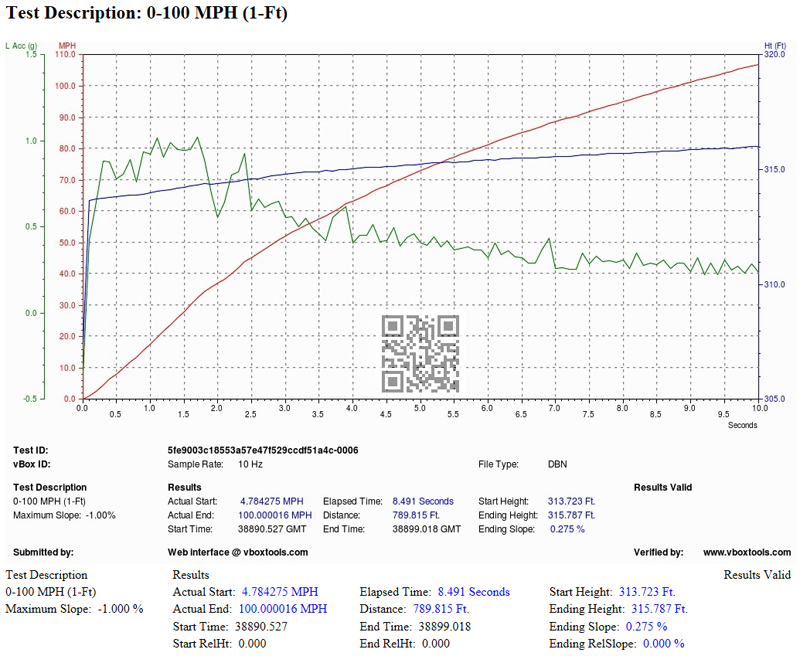

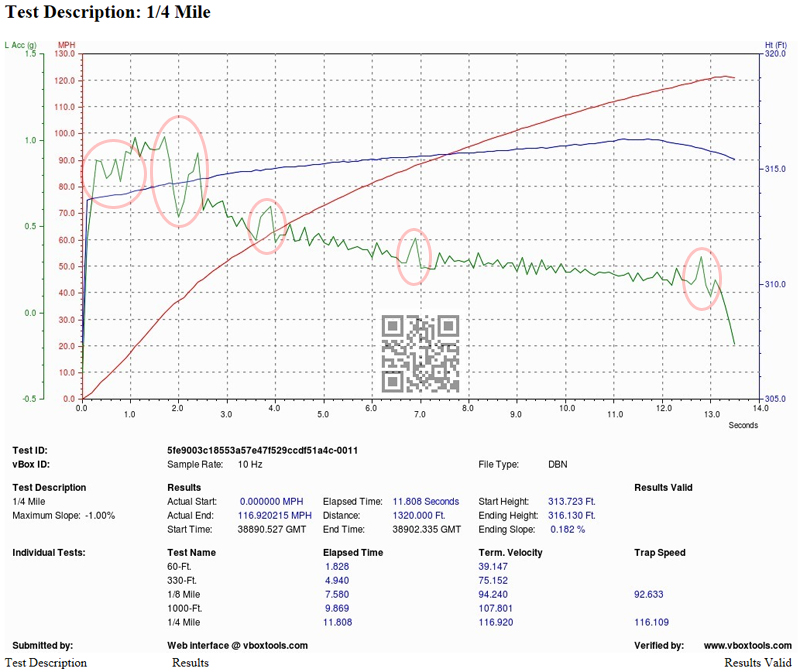

Whilst this piece of benchmark data will be quite specific, it will give a baseline for where the car is at the moment in its stock state. As I progress I will be gaining more data, not just from the drag strip, but also from getting VBOX logs for acceleration and in-gear performance. I have a lot of data from my previous A45 (which will be a good comparison), together with other RS3 data I have from a REVO tuned Stage 1 and MRC Stage 3 car. I’ll be overlaying and all sorts, so this will be interesting moving forward. Of course I’ll also gather dyno information as I progress… again, I can overlay this data against my A45 for comparison.

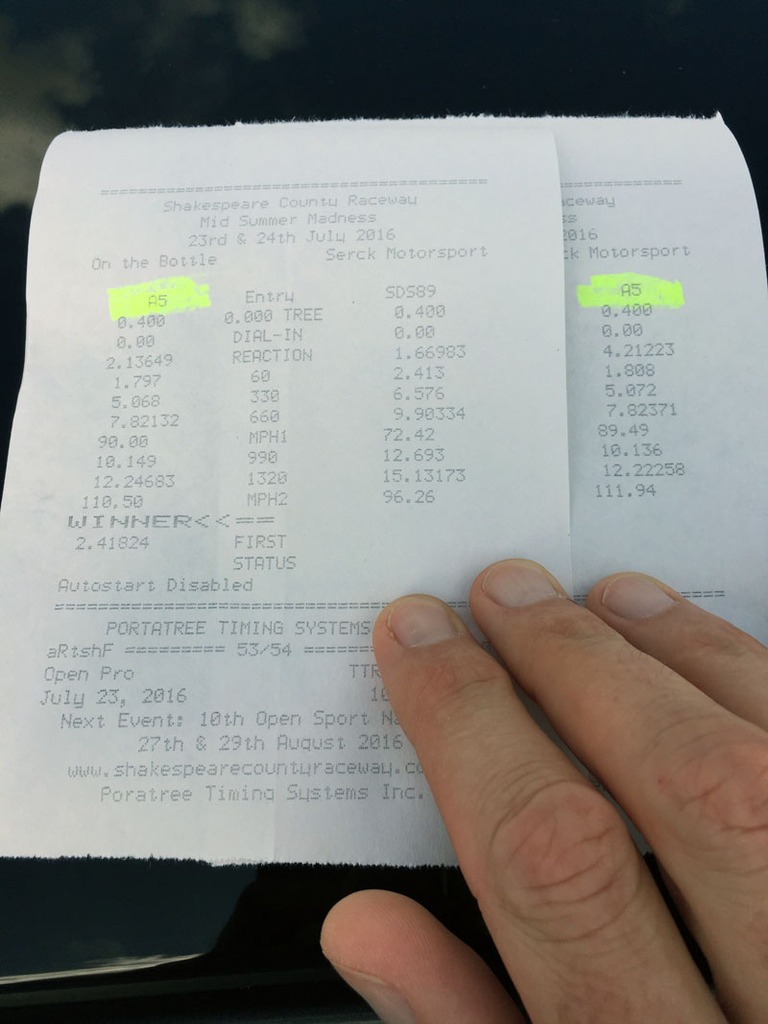

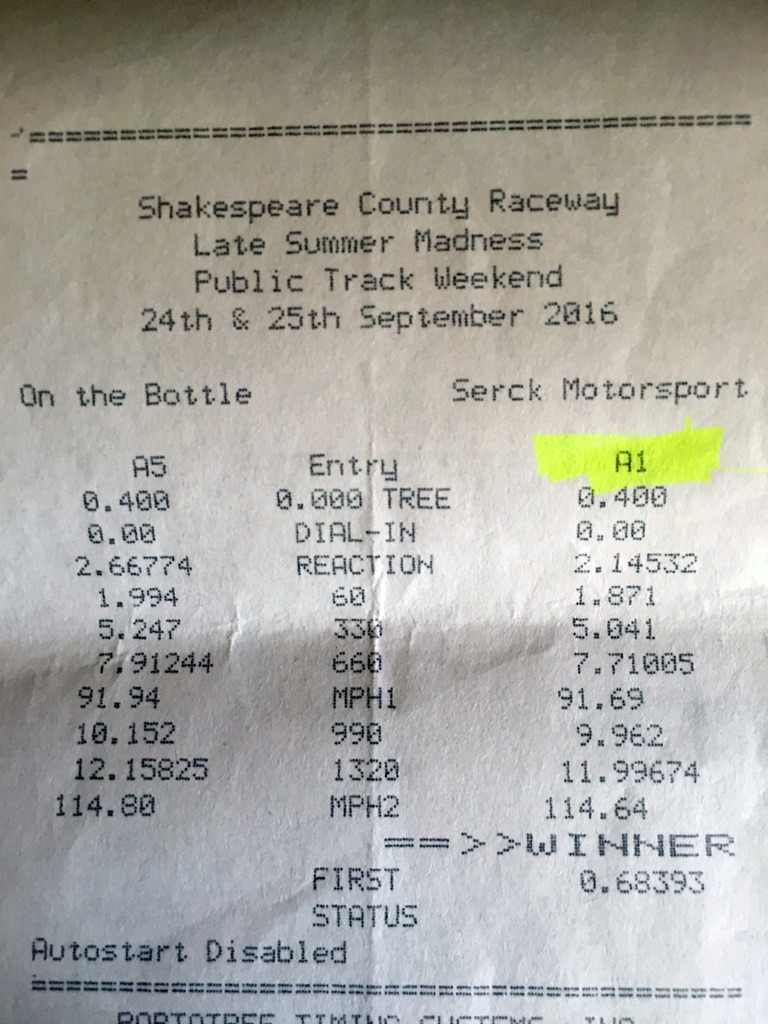

Shakespeare County Raceway

So three weeks back, after running the car in (just over 1k on the clock), I ventured down to Shakespeare to see what my stock car would do. Obviously the engine would still be fairly tight, but I needed to get some baseline data in.

As they say….. The bull**** stops when the flag drops. You’ll hear me repeat that quite a few times throughout this project thread!

I haven’t had the car on the weighbridge yet (will do though) but it is pretty highly spec’d, at least in regards to the “added weight” options! Lol Good for the gadgets…. Not so great for acceleration.

I personally prefer Shakespeare as it’s normally quieter than the Pod…. this day was no exception.

It was a warm day, circa 24degs and little to no wind. The downside was that the track had not been used in a few weeks and it had been raining the day before. Surface prep is key at these places.

I don't really like running early on, especially when no events were the previous day. You tend to find the start line will be a tad "waxy" until some rubber goes down and the track heat starts to build up a bit.

I understand that the RS3 suffers with intercooler issues in warm weather (the A45 charge cooler was unbelievably efficient and effective), so to some degree I wasn’t expecting the car to perform it’s best.

After signing on you need to get your car scrutineered. Not something you need to do at Santa Pod. The rules are the rules though! Lol Thankfully being a new car, it didn’t take long. The scrutineers laughed when they found out how many miles were on it.

Once scrutineered you’re given a running number, which is painted (don’t worry it comes off) on your back screen. Well, they gotta know which car to log the times against.

It was a shame I didn’t arrive a couple of minutes earlier…. I could have bagged “A3” as my number!!!!

So with the car ready, I went down to the “fire up lane” in readiness for my virgin run in the RS3.

Yes… I was first in line.

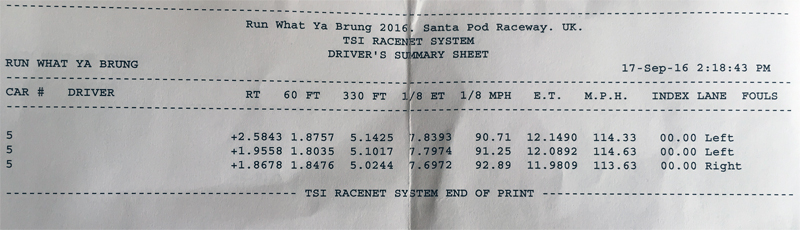

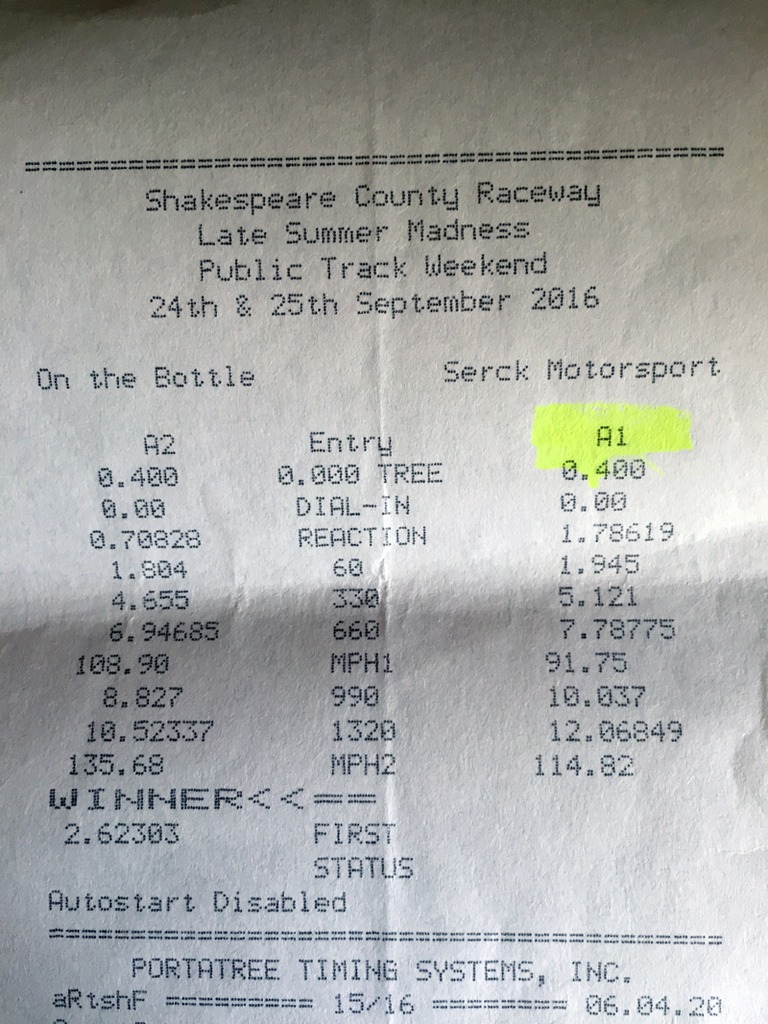

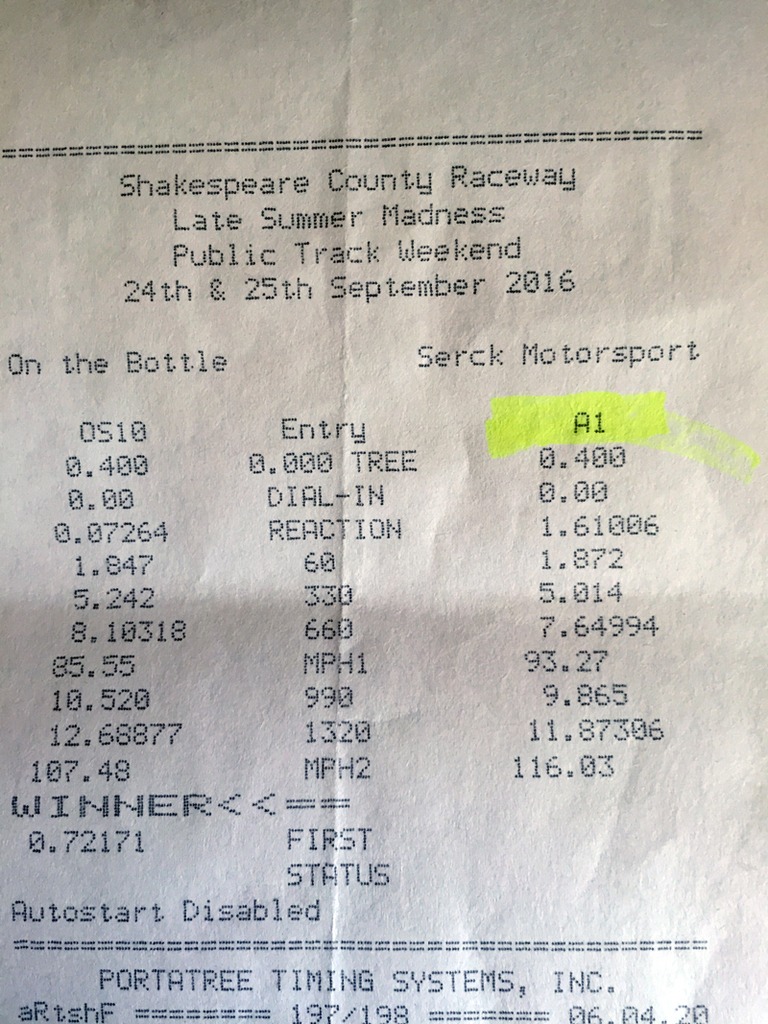

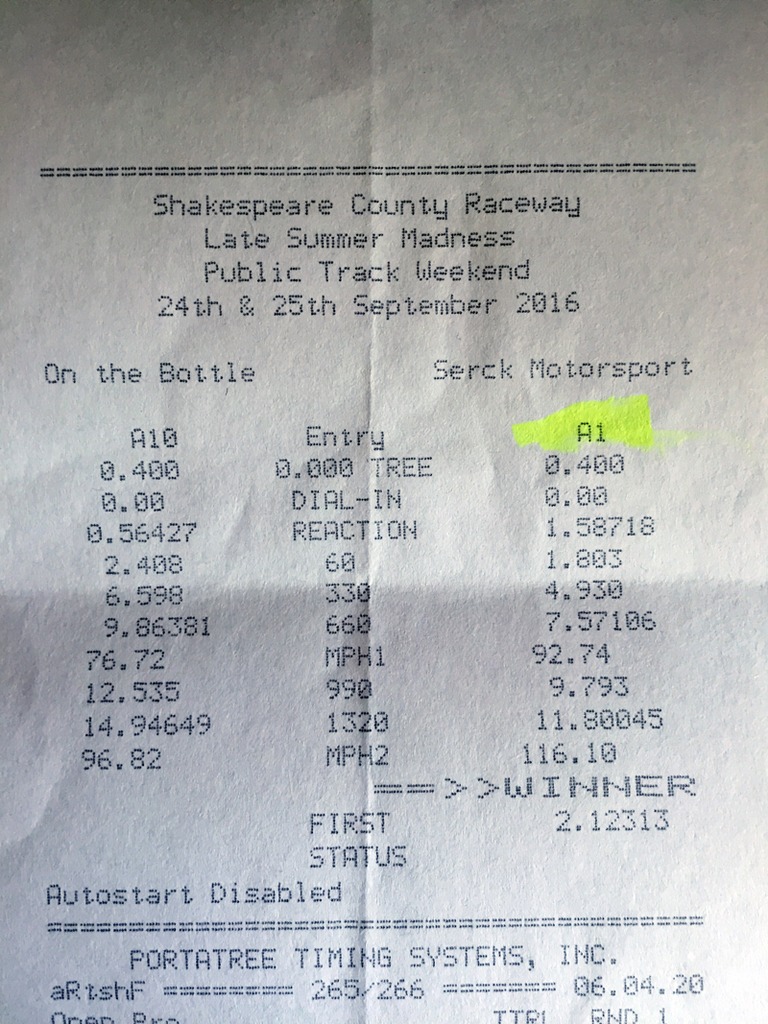

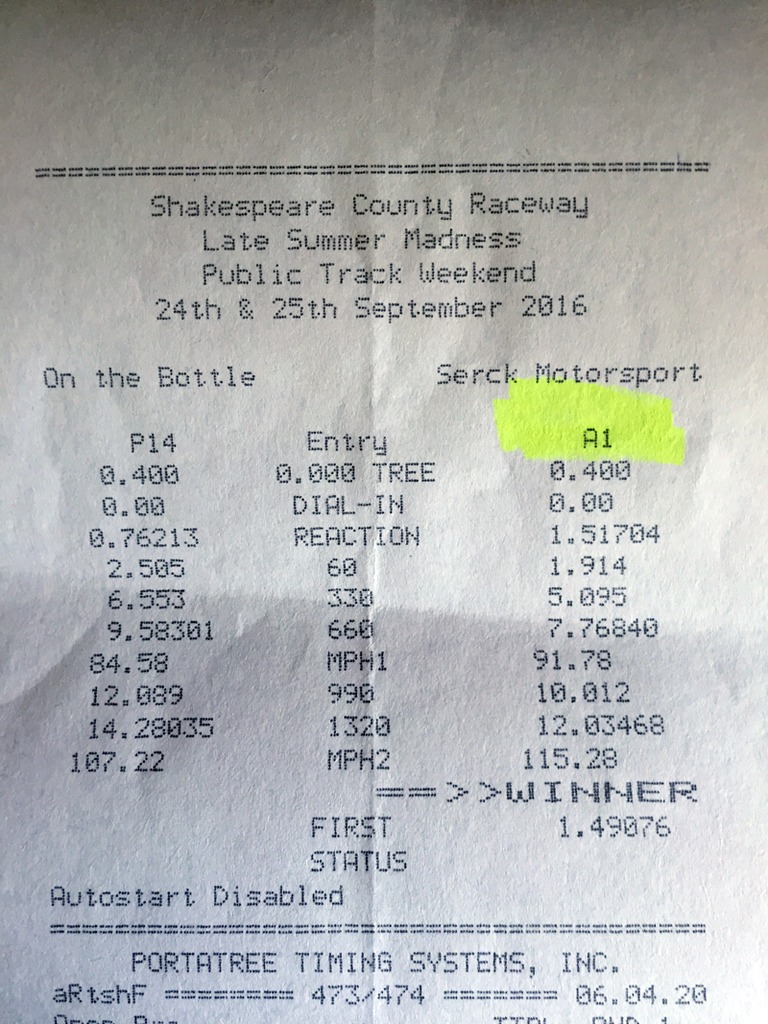

First run 12.22 @ 111.94mph

Believe it or not this was the first time I had actually launched the RS3. I was a bit nervous I was going to ***** it up, but unlike the A45 LC, the RS3 is so much easier to set-up. And unlike my A45, the RS3 just gripped and went like a stabbed rate off the line. Christ the LC on the RS3 is smooth…. Like so smooth. The gearbox as well is a country mile better than the Mercs on the strip. The whole run just went ahead with no drama….. It felt good, which the time and terminal speed showed. This is pretty damn quick for a stock hatchback.

Second run 12.24 @ 110.50mph

Felt just as good as the first run….. How’s the time for consistency. Lol Not sure why the trap speed had decreased… could have been heat soak perhaps.

Now normally I’d be getting really **** and checking / playing with tyre pressures (lowering pressures can aid launch grip), but since this car just launched with no wheel spin or axle tramp, I really didn’t see the need to faff around with anything. The 60ft times back that up with a good 1.79s and 1.80s respectively.

Quite abnormal for me I decided at this point to hand in the gloves. I was happy with those times with a stock car, and as they were so close on both runs, I didn’t think there was much point in further runs. In reality I should have parked the car up and ran later on in the day, once more rubber had been put down…. It may have helped.

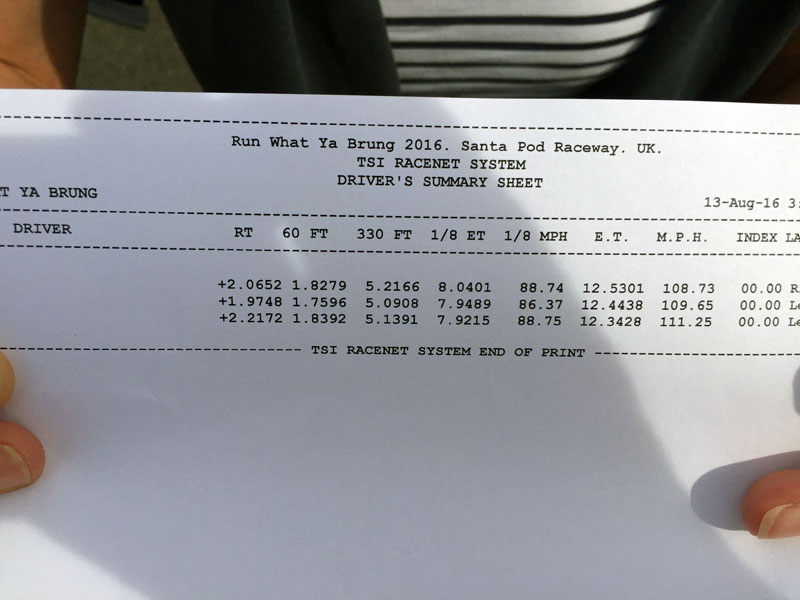

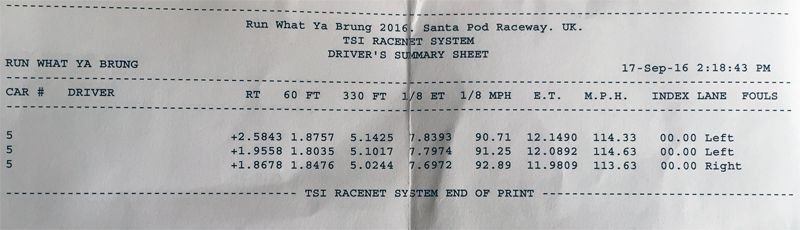

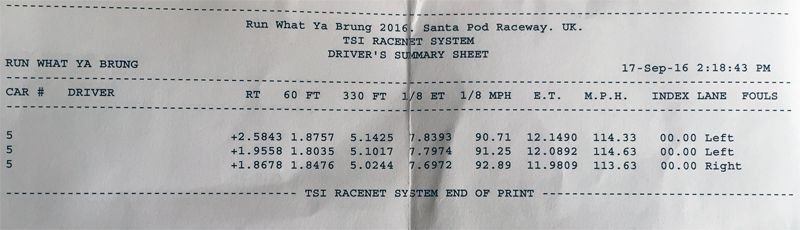

Santa Pod

This weekend I decided to take the car down the strip again….. Just for a bit of fun of course! This time though I was going to use the UK’s de facto drag strip. Santa Pod.

The reason for going in reality was I wanted to see if I could better the previous 12.2 and also try a different launch technique to see if I could bring the 60ft time down. Improving the 60ft time can have a dramatic affect on the ET’s.

Luckily the day was dry, sunny but was once again warm. Certainly felt warmer than the 25deg ambient suggested. The event was pretty busy as well. Not great and something I don’t really like about the Pod…. it tends to get very busy, which means you spend a lot of time queuing for your next run. Not ideal by any stretch.

I actually didn’t arrive until lunch time, but I had already heard via whatsapp that the track appeared to be running slower than normal (based on the times that other guys were getting - not in RS3’s mind). There was also a cross wind…. again pretty normal for the Pod.

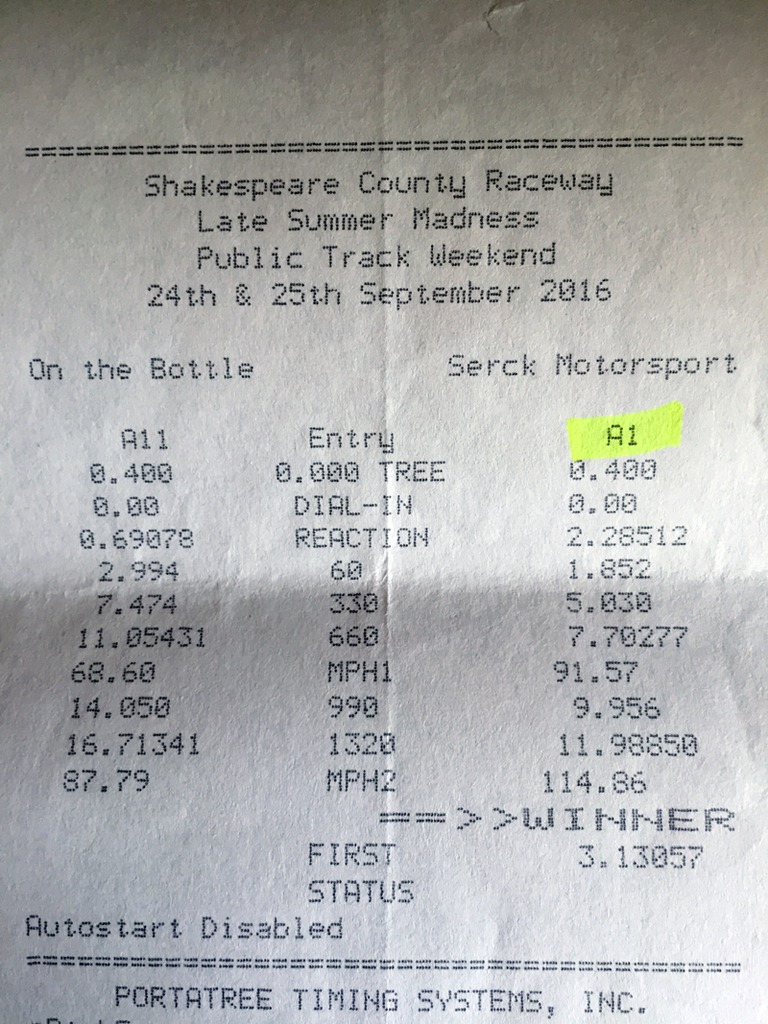

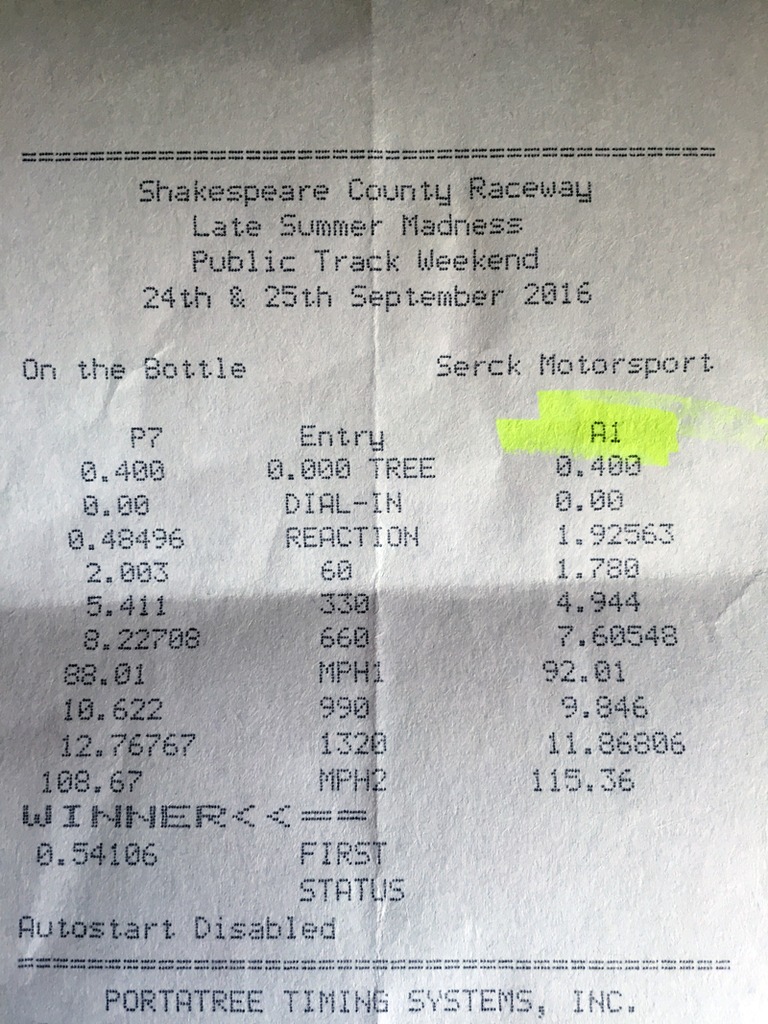

First run 12.53 @ 108.73

For the first run I launched as I had previously as Shakespeare, using Sports mode on the ESC. It felt good and smooth….. Until I saw my timing slip. Christ that wasn’t good at all. Lol 60ft wasn’t brilliant at 1.82s, but certainly nothing that made me think that was the reason for the slower ET.

Second run 12.44 @ 109.65

Due to the amount of cars running and I did rejoin the queue straight away, I had to wait nearly an hour for the next run. I forgot to take my OBD logger with me, but my charge inlet temps must have been sky high.

This time I tried launching with the ESC OFF.

As soon as the car launched it lit the front tyres up and I had slight axle tramp. Because of this I thought the run was not as good, but it certainly bettered the previous run. The 60ft time had dropped to a good 1.75s, which was where I really wanted to be.

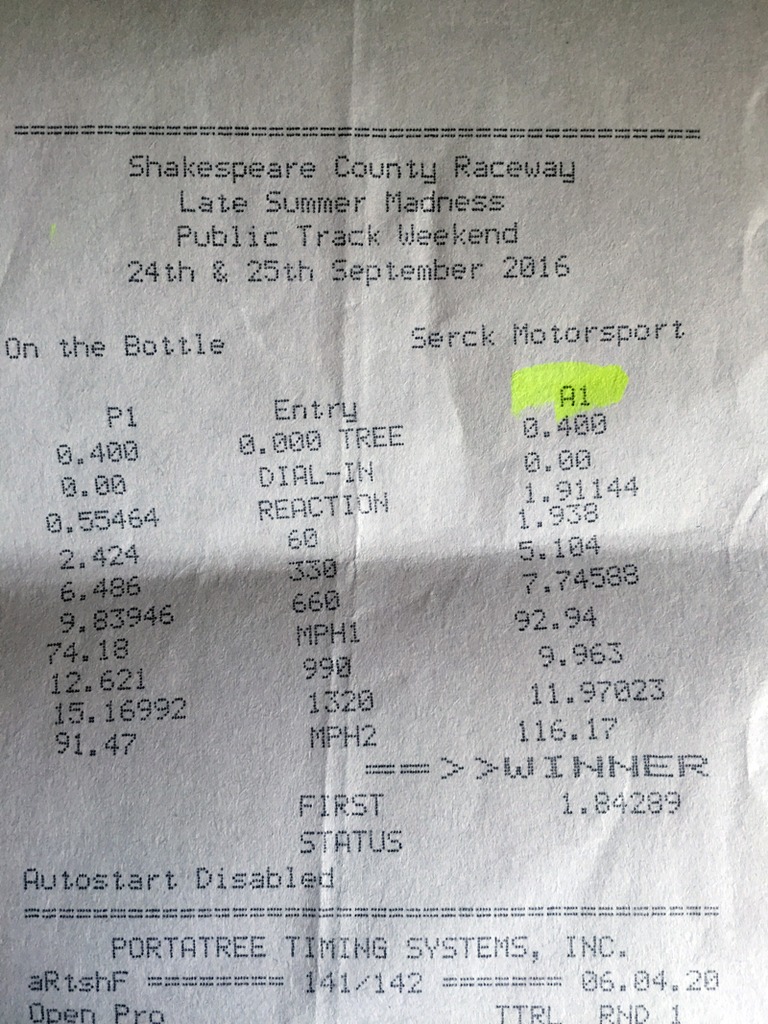

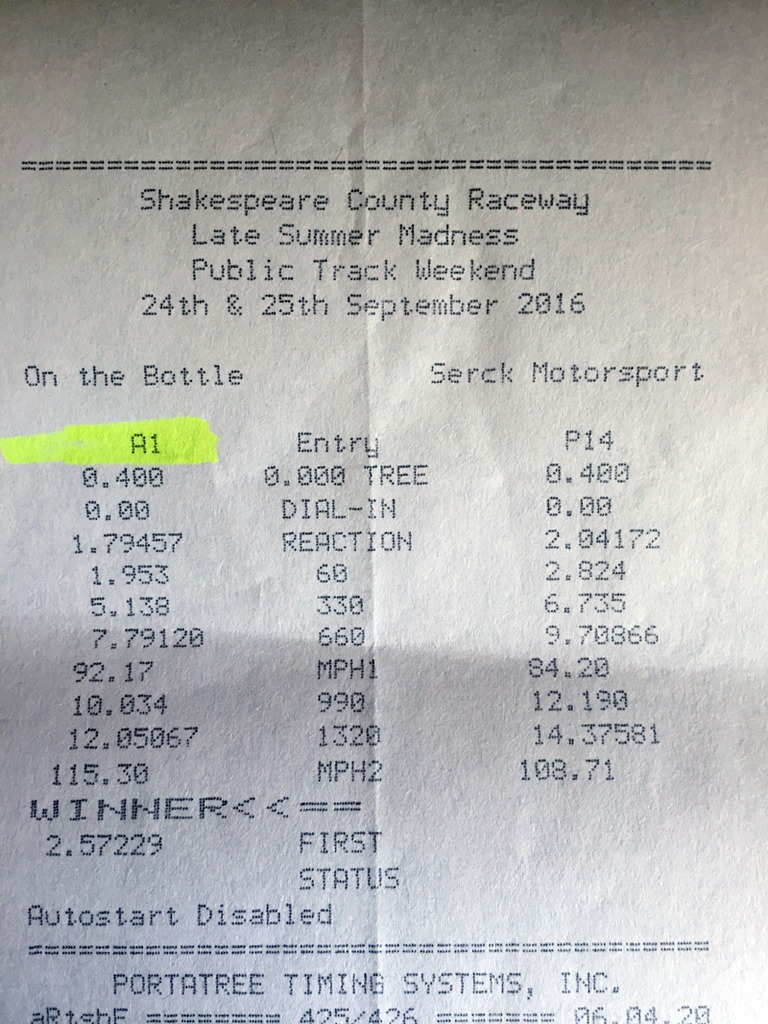

Third run 12.34 @ 111.25

Again, well over another hour had passed before getting my third run in.

For this run I went back to the ESC in Sports Mode, just to see what would happen to the 60ft. It went back up to 1.83, but the overall run was quicker and with a better trap speed. Not sure if the track was starting to improve or what.

Anyway… it was now just before 4pm and I didn’t think there was much more reason to carry on, so I called it a day.

Of course I was hoping I could achieve a better time overall at either event, but all things considered it’s bloody quick for a stock hatchback. As a comparison my previous A45 was no quicker down the strip when it had a Tuning Box fitted (running 12.2s). Stock, the A45 runs around a 12.7s quarter.

At the end of the day this provides a baseline…… future times will be a good comparison.

I hope to be back down the strip in September once I’ve added the first round of mods.

Whilst this piece of benchmark data will be quite specific, it will give a baseline for where the car is at the moment in its stock state. As I progress I will be gaining more data, not just from the drag strip, but also from getting VBOX logs for acceleration and in-gear performance. I have a lot of data from my previous A45 (which will be a good comparison), together with other RS3 data I have from a REVO tuned Stage 1 and MRC Stage 3 car. I’ll be overlaying and all sorts, so this will be interesting moving forward. Of course I’ll also gather dyno information as I progress… again, I can overlay this data against my A45 for comparison.

Shakespeare County Raceway

So three weeks back, after running the car in (just over 1k on the clock), I ventured down to Shakespeare to see what my stock car would do. Obviously the engine would still be fairly tight, but I needed to get some baseline data in.

As they say….. The bull**** stops when the flag drops. You’ll hear me repeat that quite a few times throughout this project thread!

I haven’t had the car on the weighbridge yet (will do though) but it is pretty highly spec’d, at least in regards to the “added weight” options! Lol Good for the gadgets…. Not so great for acceleration.

I personally prefer Shakespeare as it’s normally quieter than the Pod…. this day was no exception.

It was a warm day, circa 24degs and little to no wind. The downside was that the track had not been used in a few weeks and it had been raining the day before. Surface prep is key at these places.

I don't really like running early on, especially when no events were the previous day. You tend to find the start line will be a tad "waxy" until some rubber goes down and the track heat starts to build up a bit.

I understand that the RS3 suffers with intercooler issues in warm weather (the A45 charge cooler was unbelievably efficient and effective), so to some degree I wasn’t expecting the car to perform it’s best.

After signing on you need to get your car scrutineered. Not something you need to do at Santa Pod. The rules are the rules though! Lol Thankfully being a new car, it didn’t take long. The scrutineers laughed when they found out how many miles were on it.

Once scrutineered you’re given a running number, which is painted (don’t worry it comes off) on your back screen. Well, they gotta know which car to log the times against.

It was a shame I didn’t arrive a couple of minutes earlier…. I could have bagged “A3” as my number!!!!

So with the car ready, I went down to the “fire up lane” in readiness for my virgin run in the RS3.

Yes… I was first in line.

First run 12.22 @ 111.94mph

Believe it or not this was the first time I had actually launched the RS3. I was a bit nervous I was going to ***** it up, but unlike the A45 LC, the RS3 is so much easier to set-up. And unlike my A45, the RS3 just gripped and went like a stabbed rate off the line. Christ the LC on the RS3 is smooth…. Like so smooth. The gearbox as well is a country mile better than the Mercs on the strip. The whole run just went ahead with no drama….. It felt good, which the time and terminal speed showed. This is pretty damn quick for a stock hatchback.

Second run 12.24 @ 110.50mph

Felt just as good as the first run….. How’s the time for consistency. Lol Not sure why the trap speed had decreased… could have been heat soak perhaps.

Now normally I’d be getting really **** and checking / playing with tyre pressures (lowering pressures can aid launch grip), but since this car just launched with no wheel spin or axle tramp, I really didn’t see the need to faff around with anything. The 60ft times back that up with a good 1.79s and 1.80s respectively.

Quite abnormal for me I decided at this point to hand in the gloves. I was happy with those times with a stock car, and as they were so close on both runs, I didn’t think there was much point in further runs. In reality I should have parked the car up and ran later on in the day, once more rubber had been put down…. It may have helped.

Santa Pod

This weekend I decided to take the car down the strip again….. Just for a bit of fun of course! This time though I was going to use the UK’s de facto drag strip. Santa Pod.

The reason for going in reality was I wanted to see if I could better the previous 12.2 and also try a different launch technique to see if I could bring the 60ft time down. Improving the 60ft time can have a dramatic affect on the ET’s.

Luckily the day was dry, sunny but was once again warm. Certainly felt warmer than the 25deg ambient suggested. The event was pretty busy as well. Not great and something I don’t really like about the Pod…. it tends to get very busy, which means you spend a lot of time queuing for your next run. Not ideal by any stretch.

I actually didn’t arrive until lunch time, but I had already heard via whatsapp that the track appeared to be running slower than normal (based on the times that other guys were getting - not in RS3’s mind). There was also a cross wind…. again pretty normal for the Pod.

First run 12.53 @ 108.73

For the first run I launched as I had previously as Shakespeare, using Sports mode on the ESC. It felt good and smooth….. Until I saw my timing slip. Christ that wasn’t good at all. Lol 60ft wasn’t brilliant at 1.82s, but certainly nothing that made me think that was the reason for the slower ET.

Second run 12.44 @ 109.65

Due to the amount of cars running and I did rejoin the queue straight away, I had to wait nearly an hour for the next run. I forgot to take my OBD logger with me, but my charge inlet temps must have been sky high.

This time I tried launching with the ESC OFF.

As soon as the car launched it lit the front tyres up and I had slight axle tramp. Because of this I thought the run was not as good, but it certainly bettered the previous run. The 60ft time had dropped to a good 1.75s, which was where I really wanted to be.

Third run 12.34 @ 111.25

Again, well over another hour had passed before getting my third run in.

For this run I went back to the ESC in Sports Mode, just to see what would happen to the 60ft. It went back up to 1.83, but the overall run was quicker and with a better trap speed. Not sure if the track was starting to improve or what.

Anyway… it was now just before 4pm and I didn’t think there was much more reason to carry on, so I called it a day.

Of course I was hoping I could achieve a better time overall at either event, but all things considered it’s bloody quick for a stock hatchback. As a comparison my previous A45 was no quicker down the strip when it had a Tuning Box fitted (running 12.2s). Stock, the A45 runs around a 12.7s quarter.

At the end of the day this provides a baseline…… future times will be a good comparison.

I hope to be back down the strip in September once I’ve added the first round of mods.

#6

Scooby Regular

Thread Starter

Feedback on some of the common “issues”

I thought I would also add some feedback on my experiences over the past 3k miles of use in respect of, shall we say, some of the more common problems reported with the RS3.

To add some context this is a second car for me. More of a weekend blaster in reality. However, saying this I have managed to cover just over 3k miles in 12 weeks. This has predominantly been down to the running in, wanting to get that out of the way, and also a Scotland Road Trip I undertook in the RS3 last week.

I’ll digress slightly, but if you have never done a full on road trip around Scotland…. I would highly recommend you do it.

I’ve been threatening to do this for years and now wish I had years ago.

What a fantastic place to drive…. Yes there are still places in the UK for doing that! And the scenery… simply wow!

Over 6 days we covered just over 1500 miles in the RS3, and it was faultless from a drivers perspective. Opening the car up over the highlands was great and the car was effortless to drive quickly.

Oil Consumption

I haven’t owned a VAG car for some years now, and when I did they weren’t renowned for chomping oil. Whilst I’m not suggesting they are chompers now, they do appear to have a leaning towards an engine that tends to consume oil. Due to this I have regularly monitored the oil level.

Prior to going on the trip to Scotland the dipstick was at MAX, so that was after 1500 miles.

As soon as arrived back at home (just over 3k miles in total), I parked the car up in the garage and left it for 10 mins and then checked the dipstick.

As you can see it is virtually MAX.

The next morning I checked it again (cold) and it was at the same level one side and two diamonds down from MAX on the other side.

After I went down Santa Pod at the weekend I checked it again when home (warm). It had returned to MAX on both sides.

If it’s used any oil over the past 3k miles it is certainly minimal.

I’m quite **** about the running in process and whilst I don’t smash the backside out of the engine during that period, I certainly ensure it gets a varied workout, with plenty of mixed loading. Using the box often and engine braking quite a lot. Whether this has helped with my oil usage, who knows, but it’s the approach I have always taken with new engines.

I will obviously still monitor oil usage but based on what I’ve done so far I can’t see consumption being an issue, especially as I’ll normally only do around 5k per year and I’m on fixed 12 month services.

Brake Squeal

Not one bit of squeal or brake performance issue so far. Not saying it won’t happen, but nothing has materialised yet. Discs are clean and pads look 100% with no sign of accelerated wear.

Knocking Rear Top Mounts

Quiet and no noise. My car is a March 16 build date iirc, so not sure if that makes a difference. Again, no issues thus far.

The car had quite a heavy workout over the Highlands, but as of yet, none of the common issues have really reared their heads.

We’ll obviously see how this goes moving forward.

I thought I would also add some feedback on my experiences over the past 3k miles of use in respect of, shall we say, some of the more common problems reported with the RS3.

To add some context this is a second car for me. More of a weekend blaster in reality. However, saying this I have managed to cover just over 3k miles in 12 weeks. This has predominantly been down to the running in, wanting to get that out of the way, and also a Scotland Road Trip I undertook in the RS3 last week.

I’ll digress slightly, but if you have never done a full on road trip around Scotland…. I would highly recommend you do it.

I’ve been threatening to do this for years and now wish I had years ago.

What a fantastic place to drive…. Yes there are still places in the UK for doing that! And the scenery… simply wow!

Over 6 days we covered just over 1500 miles in the RS3, and it was faultless from a drivers perspective. Opening the car up over the highlands was great and the car was effortless to drive quickly.

Oil Consumption

I haven’t owned a VAG car for some years now, and when I did they weren’t renowned for chomping oil. Whilst I’m not suggesting they are chompers now, they do appear to have a leaning towards an engine that tends to consume oil. Due to this I have regularly monitored the oil level.

Prior to going on the trip to Scotland the dipstick was at MAX, so that was after 1500 miles.

As soon as arrived back at home (just over 3k miles in total), I parked the car up in the garage and left it for 10 mins and then checked the dipstick.

As you can see it is virtually MAX.

The next morning I checked it again (cold) and it was at the same level one side and two diamonds down from MAX on the other side.

After I went down Santa Pod at the weekend I checked it again when home (warm). It had returned to MAX on both sides.

If it’s used any oil over the past 3k miles it is certainly minimal.

I’m quite **** about the running in process and whilst I don’t smash the backside out of the engine during that period, I certainly ensure it gets a varied workout, with plenty of mixed loading. Using the box often and engine braking quite a lot. Whether this has helped with my oil usage, who knows, but it’s the approach I have always taken with new engines.

I will obviously still monitor oil usage but based on what I’ve done so far I can’t see consumption being an issue, especially as I’ll normally only do around 5k per year and I’m on fixed 12 month services.

Brake Squeal

Not one bit of squeal or brake performance issue so far. Not saying it won’t happen, but nothing has materialised yet. Discs are clean and pads look 100% with no sign of accelerated wear.

Knocking Rear Top Mounts

Quiet and no noise. My car is a March 16 build date iirc, so not sure if that makes a difference. Again, no issues thus far.

The car had quite a heavy workout over the Highlands, but as of yet, none of the common issues have really reared their heads.

We’ll obviously see how this goes moving forward.

#7

Scooby Regular

Thread Starter

Rear RS Badge

Decided to replace the rear RS3 badge today, with the black one recently purchased.

This time I wanted to mark the original badge out as this is a three piece badge.

All I did was mask below the original badge and mark where each specific character was…. Saves any guessing come positioning of the new one!

Same kind of deal as with the removal of the rear rings. Apply heat and then slip a credit card down, however, when it came to removing the R and red block that method didn’t work.

Due to that part of the badge being mega flush with the panel I had to use some dental floss (couldn’t get the card behind), which acted like a cheese wire. Just hook it around the top left hand corner and slower pull it behind the badge to the opposite corner. Comes off in seconds that way.

Once removed I cleaned it up as with the rings.

With the guide in place and the relevant marks, repositioning the new badge is really easy. The characters on the new badge were ever so slightly smaller, but it doesn’t make any different in reality.

I might be tempted to pull the rear exhaust tips off and get them powder coated in black, when I get the wheels done. Just to finish off the rear.

Due to get the car on the dyno this coming bank holiday weekend, fit the secondary decats and Tuning Box. That’s when I can get stuck into the logging and the real fun begins.

Decided to replace the rear RS3 badge today, with the black one recently purchased.

This time I wanted to mark the original badge out as this is a three piece badge.

All I did was mask below the original badge and mark where each specific character was…. Saves any guessing come positioning of the new one!

Same kind of deal as with the removal of the rear rings. Apply heat and then slip a credit card down, however, when it came to removing the R and red block that method didn’t work.

Due to that part of the badge being mega flush with the panel I had to use some dental floss (couldn’t get the card behind), which acted like a cheese wire. Just hook it around the top left hand corner and slower pull it behind the badge to the opposite corner. Comes off in seconds that way.

Once removed I cleaned it up as with the rings.

With the guide in place and the relevant marks, repositioning the new badge is really easy. The characters on the new badge were ever so slightly smaller, but it doesn’t make any different in reality.

I might be tempted to pull the rear exhaust tips off and get them powder coated in black, when I get the wheels done. Just to finish off the rear.

Due to get the car on the dyno this coming bank holiday weekend, fit the secondary decats and Tuning Box. That’s when I can get stuck into the logging and the real fun begins.

Trending Topics

#8

Scooby Regular

Join Date: Jul 2014

Location: Staffordshire

Posts: 106

Likes: 0

Received 0 Likes

on

0 Posts

Subscribed.i took the new rs3 for a test drive saturday.i was very impressed.the only thing i noticed was for a 2.5 i thought it would spoil up slightly quicker from a standing start.i had the s3 last year with the dsg which as a all round car brilliant.the noise the 2.5 kicks out is stunning.is there a limit you can fettle with them before you lose the warrenty

#9

Scooby Regular

Thread Starter

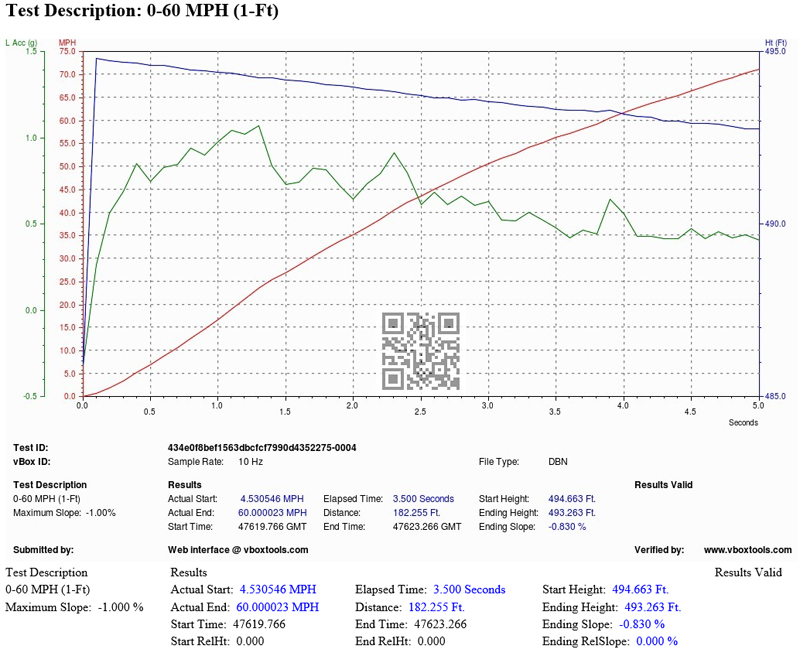

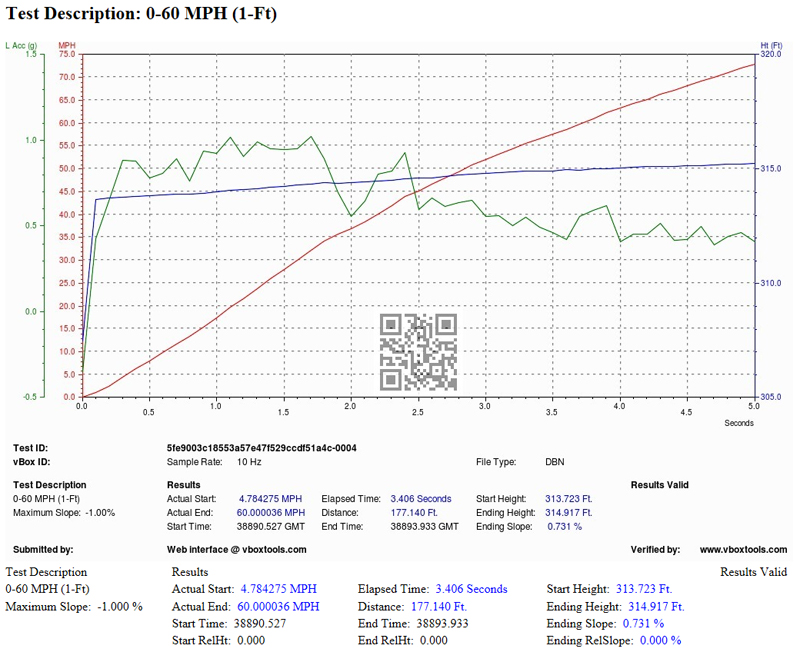

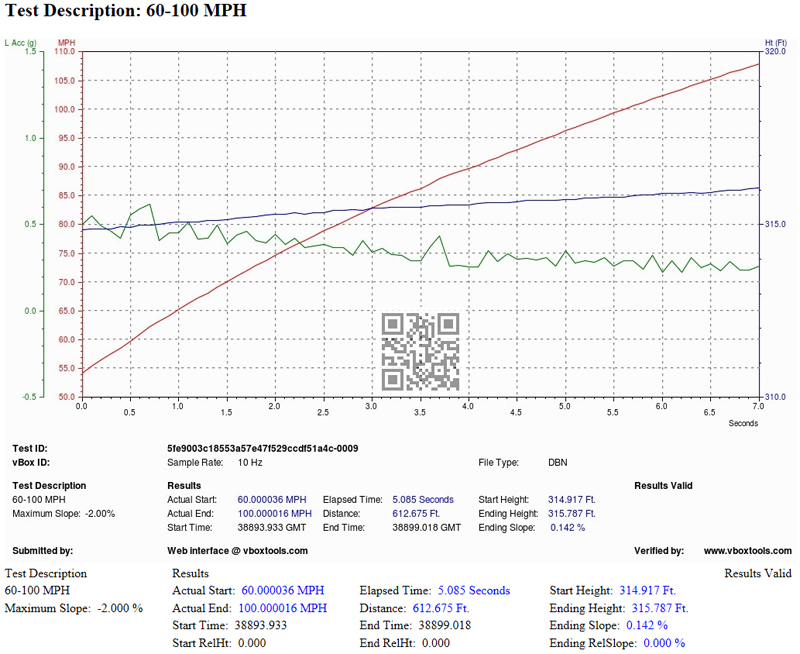

Not sure what you mean about spooling up from a standing start..... a stock RS3 can do the 60 dash in around 3.5s with rollout (3.7s ish without rollout) being taken into consideration. lol

Warranty could be void as soon as you do anything from stock mate..... like with any car. VAG are particularly strict on mods.

Warranty could be void as soon as you do anything from stock mate..... like with any car. VAG are particularly strict on mods.

#12

Scooby Regular

Thread Starter

I've taken the intro / explanation out of what I've posted elsewhere..... you guys have seen / read it all before. I'm just going to get down to the real meat here!

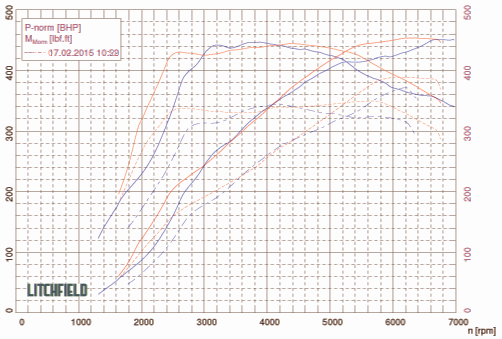

TEST 1 - Baseline Figure

Apologies as I’m awaiting the separate stock graph PDF to be sent to me. I’ll update this as soon as I have it. The graph is used on some of the overlays seen further on, so at least we have clear reference points at the moment to discuss.

Summary of Spec

Standard MY16 RS3

Fuel - VPower Nitro (99 oct)

TEST 1 figure achieved was 388bhp & 350lbft @ the flywheel

TEST 1 - Baseline Figure - Comments

Well we already appreciate how quick this car is, even in standard form on the black stuff. But in reality this is due to a number of things. The area under the curve, the gearbox and Haldex system - as a complete package it pretty much rocks, but what does the “pretty” graph tell us about the power delivery.

The area under the curve is always more relevant than the peak figures.

I can normally look at an entire power graph and make a decent judgement as to the potential of the power delivery and flexibility on the road, taking into account the power band and torque available. Make no mistake, it’s the torque that gets you to where you want to go…. Quicker.

Since the MAHA RR is able to appropriately load the engine up, you can deduce how the turbo comes on song. You can see here that you’re achieving near (around 340lbft) peak torque at around 2600rpm, which in 4th gear is pretty good. Suffice to say, due to loading, you will see peak torque coming in slightly earlier the higher the gear. So 5th would see this 2800rpm drop slightly….. this is all normal (3rd gear would be slightly later and so on).

Low rpm’s for torque makes for more pace from lower revs, however by looking at this torque curve you see the RS3 holds this torque pretty well all the way through to 5800rpm. For a road car that is a nice torque band. This is why the mid-range feels really strong on the RS3 and explains why the engine keeps pulling through the rev range. When you combine a wide torque band, with an early onset of torque, you end up with a very agile package.

There are a few peaks and troughs throughout the torque curve, but these don’t really “get in the way” of the power delivery. We’ll come on this later.

When we also see how much more power/torque this turbo can provide further on, it makes the overall set-up even more amazing.

So what else can we find out?

Another advantage of most rolling roads is that you can also capture and overlay other data, that is gathered at the time of the dyno run. This data either comes from plugging the dyno into your OBD port, or buy connecting additional sensors to the dyno, directly connected to the car.

I did capture a lot of data on all runs but it was a mix between additional sensors (true wide band sensor), ODB to dyno and also using VCDS. Which leads me on to the next subject….

VCDS (previously known as VAGCOM)

I won’t bore you guys with talking about what VCDS is…. I’m suspecting most of you guys know, but what I will concentrate on is talking about the logging facilities as this was the real reason why I purchased VCDS.

In basic terms the ECU reads a varied number of sensors (some dependant on OEM ECU version). Upon looking at the sensor readings available via VCDS, you may be overwhelmed by what data sets can be logged.

You may be thinking why I can’t just plug in a simple OBD reader into the car and use a smartphone app etc to read the sensors. The main constraint with this is that these loggers / scanners only read generic OBD codes (PID’s) generally. Some applications will also decipher / read manufacturer specific codes, but not to the extent that VCDS does. VCDS reads all the VAG sensors that I’m aware of, and it’s access to this information that I wanted.

Whilst some may be meaningful, others will have the reaction of "What the hell does that mean?". Obviously to a professional or knowledgeable enthusiast, this will equate to useful data but in reality the majority of us will neither understand or be interested to a degree...... but make no mistake they can all be meaningful.

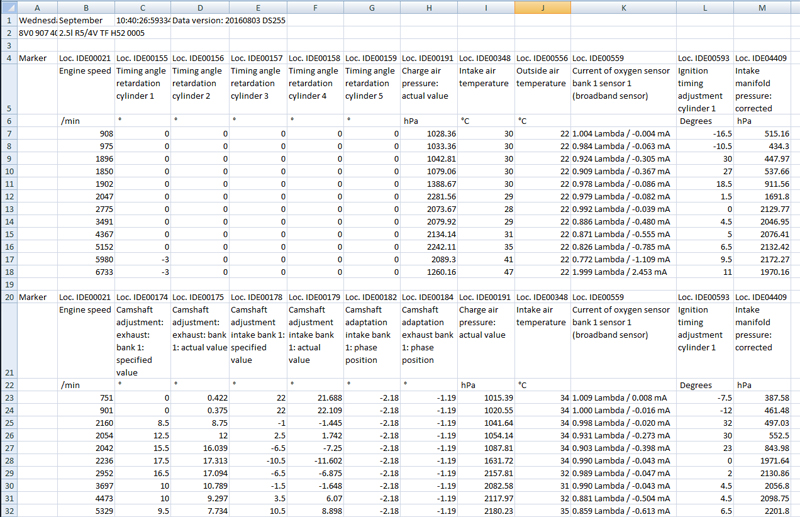

Here is a screenshot of a log I took (excuse the rather slow sample rate - that’s my fault) for the stock level of tune.

This specific screen shot shows two logs in the same file.

They both contain all sorts of data varying from timing retard per cylinder, boost, charge air temp and ambient temps, fueling, overall ignition, camshaft timing etc. You can view all sorts of useful date which is very very useful (needed) when you’re mapping. All of these are normally recorded against RPM.

There are so many different sensors and you can log up to 12 different sensors at a time in VCDS.

Stock Boost

As we’re talking about the stock tune here, you can use the screenshot above to see how much boost the car makes on a stock tune as seen at the manifold.

If you look at the Engine Speed column on the left (uppermost log) and scan across to the last column (Intake Manifold Pressure), you’ll see what boost was achieved at what RPM. Whilst the sample rate is quite slow (as in the RPM increments), this does give you a good idea of boost attained at the manifold.

You must remember that the boost shown includes 1 atmosphere of measure as these are absolute readings, so you must take 1 atmosphere (1 bar effectively) off to get an appropriate reading. These are also shown in hPa as opposed to PSI or BAR. 1000 hPa is basically 1 bar, so it doesn’t take long to work it all out.

I’ll do the conversion to BAR to make it easier for you to read:

Whilst it doesn’t show it in this log, stock boost peaks at around 1.2bar, but you can see that boost does fluctuate throughout the rev range. This is also shown in the torque curve, which for a standard car isn’t that flat to be honest. On the stock dyno runs of the RS3 you can see the torque (and power) fluctuate through the mid range, and this is largely due to boost fluctuation / control. Boost control could have been tighter to be honest, but it is what it is.

As you may expect, you can see boost tails off towards the redline (just below 1bar).

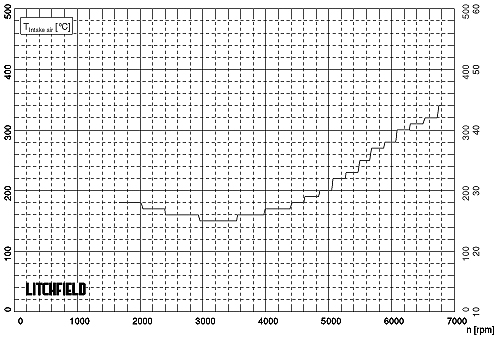

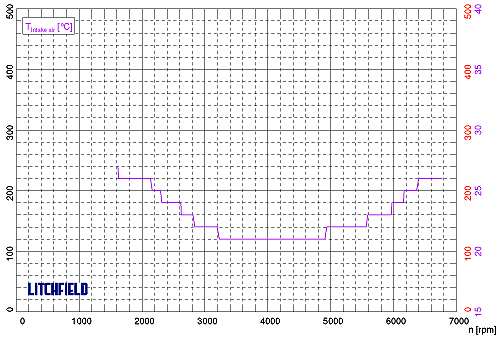

Charge Temp

Something else you can see on the above log is the Intake Air Temp which is the temperature of the air after the intercooler. This is very important for turbocharged cars and is certainly an area that can cost you power as well as gain you power.

Effectively the cooler the air entering the engine after the turbocharger (and intercooler), the more dense it is and the the bigger bang you can achieve. Figures you attain here can inform you whether you’re over heating the charge air (by running the turbo beyond its efficiency) and/or have an effective intercooler.

It’s also useful to log the ambient temperatures so you can see the delta (difference) between the two temps.

You’ll see here that the charge temp (intake) is fairly OK, but rises as the run moves through the revs and more boost is being applied and everything heats up.

Cooler charge temps are the best (icing issues to one side), but I was always told in the old days that ideally you should aim for charge temps below 40degs. Anything over that will apparently start to impact power more.

Considering this is a dyno cell, and although it has very good airflow, it can’t match the cooling the car would receive on the road, so the figures attained here on the oem setup are OK. Repeated dyno pulls will start to increase temps, but on the runs we did they quickly stabilised again.

Fuelling

Again on the same log above you’ll see fuelling being logged (shown by the column giving a Lambda reading). Ignoring the last row @ 6733 (the throttle was lifted here), the Lambda figure slowly decreases as the revs rise. This means the fuelling starts off lean (more air than fuel) and gradually richens up (more fuel) as the power / boost rises. What you would expect.

It is possible to gain power (and lose it) depending on what fueling strategy you choose. Rich or lean mixtures have their benefits and disbenefits. However, I’m led to believe that with direct injection (as used in the RS3), you have much more flexibility with what you can do with the fuelling.

Ignition

The final element to highlight is the ignition adjustment, which is also on the same log above.

Again, as the rev rise and boost builds the ignition is slowly adjusted, with stock peak ignition adjustment running at around 11degs of advance.

All the above are the basic elements to consider when tuning a turbocharged car. There are a lot more, certainly in this ECU on the RS3, but these are the basics. But you’ll probably appreciate now how important log information can be, especially when you’re looking to start tuning a car.

So with the benchmark data logged and the car pulled off the dyno…. Let’s move on to the first item to change.

Secondary Decats

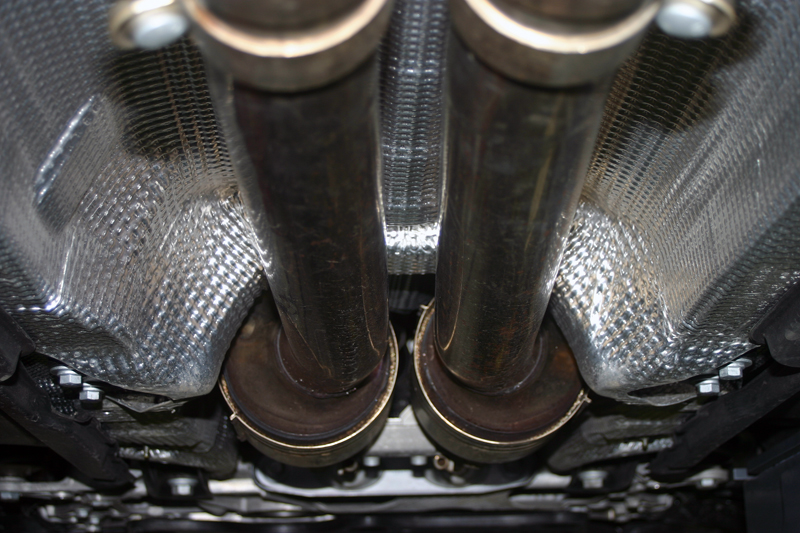

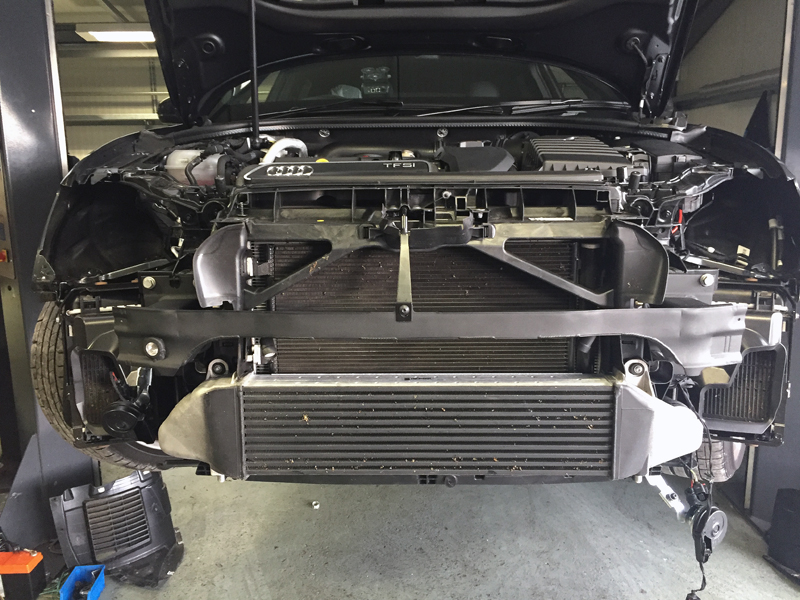

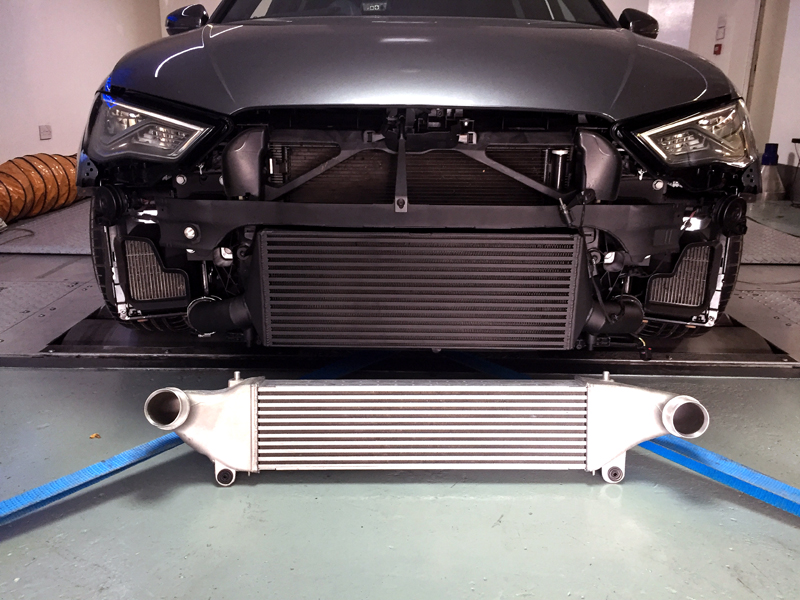

Quite a common mod on the RS3 so I thought it would be rude not to.

The RS3 has several cats, both in the downpipe and the secondary mid section. It’s the secondary ones I decided to remove as it’s a fairly straight forward and inexpensive mod.

To be honest the OEM exhaust system doesn’t look that restrictive visually, but may need to be looked at further down the line.

You’d have thought that removing a couple of cats would release some power. We’ll find out.

The main reason I chose this mod was for the noise increase though. Whilst the stock car sounds very nice, I wanted to unleash that rumble a touch more. If we saw any increase in power that would be a bonus, but it wasn’t really expected from my perspective.

These are what we’re going to remove:

These are what we’re going to replace them with, a set of Miltek secondary decat pipes:

With both sets side by side:

It’s clearly quite obvious what the difference is between the two sets of pipes!

So with the new decats on, it was time to bang the car on the dyno and see what we could see.

TEST 1 - Secondary Decats

Apologies as I’m awaiting the decta graph PDF to be sent to me. I’ll update this as soon as I have it.

Summary of Spec

MY16 RS3

Miltek Secondary Decat Pipes

Fuel - VPower Nitro (99 oct)

TEST 1 figure achieved was 394bhp & 355lbft @ flywheel

Because I haven’t got the graph in front of me I don’t have the exact figures (again apologies), but from what I remember we saw circa +6bhp and +5lbft over stock. I can’t remember whether this was only peak or throughout the rev range though. I’ll update when I get the graph in my hands.

I know others have reported more increases, but unfortunately I can only state what I

achieved. To be honest I’m not surprised.

Looking at my VCDS logs it doesn’t appear to have affected boost control, which if there was less of a restriction on the exhaust side by a tangible amount, I would expect to see changes in wastegate duty / boost achieved.

It’s sounded awesome on the dyno though….. It has a proper “growl on” when you open it up. Worth the cost 100% just for that in my opinion!

I was going to disconnect the exhaust valves as well, but never got around to it. I might revisit that in the future.

I also can’t tell you whether driveability was affected, not that I would expect this to be the case in reality to any noticeable degree. The first time I got the car on the road was after the next stage of tuning….. Which we’ll come on to next and something I’m sure you guys will be more interested in.

ECU Remap

This is undoubtedly the key element for this development phase and where most of the time has been spent.

The RS3 uses the Bosch MED 17.1.x ECU family…… without going into a massive amount of detail, this ECU is one very powerful ****. The amount of control it can have over how the engine performs is pretty mind blowing. The art of making the car “sing”, utilising/modifying the appropriate calibrations (there are well over 100,000 of these!) and ensuring you’re not hitting the protection tables (ultimately resulting in power being pulled down), is where the time and effort is needed.

It goes without saying that even from a pure technical and in essence, logical standpoint, a properly mapped ECU should be overall, far better than a tuning box (convenience to one side).

One of the plus sides of mapping the MED 17.1.x is the fact that this can be accessed fully via the OBD port. I don’t personally know if all current tuners are using this method, I suspect they are to be honest. The other method (as is the case with the A45) is via a method known as BDM. The process to achieve this is commonly referred to as a “bench tune”, which effectively means the ECU is pulled out of the car and programmed. This also makes tuning a bit of a time consuming effort, assuming you need to alter and test different calibration adjustments. It means you program the ECU (out of the car and you normally open it up); refit; log on road/dyno; pull ECU out and make adjustments and refit/log again - repeat until you get bored!

Fortunately the RS3 has OBD programming access.

So how is the programming done - put simply a laptop with the programming software is connected to the ECU via the cars OBD port, and the new map file is written to the ECU…. all in situ. It takes around 10 minutes to reprogram the ECU with each new map file.

Enough screens for you?

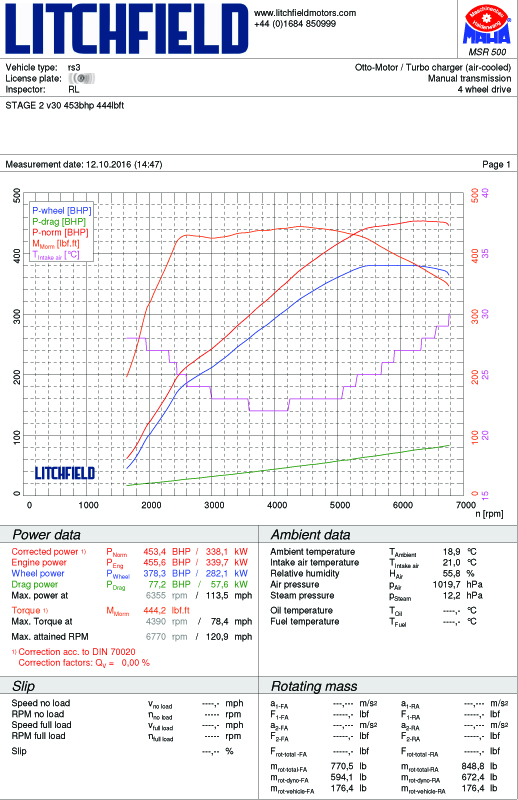

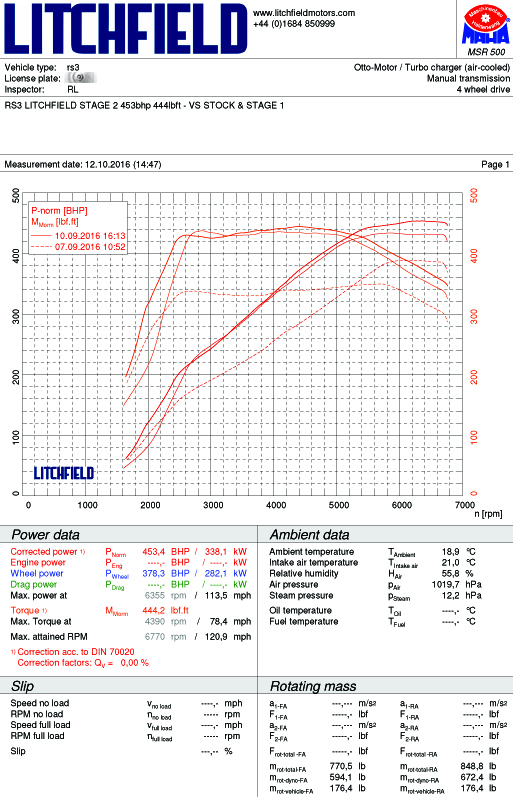

TEST 2 - ECU Remap and Secondary Decats

Whilst I’m reporting this as TEST 2, there was a whole process that we went through to get to this point. This was certainly not the first map that was created (in fact it was the last one of the day), but was where we finished up at the end of this specific session. If memory serves me correctly we created at least 7 maps, each one altering a single area to see what the effect was, then rolling up the “good” changes with the next change. Basically taking an incremental approach.

Summary of Spec

MY16 RS3

Litchfield Stage 1 ECU calibration

Miltek Secondary Decat Pipes

Fuel - VPower Nitro (99 oct)

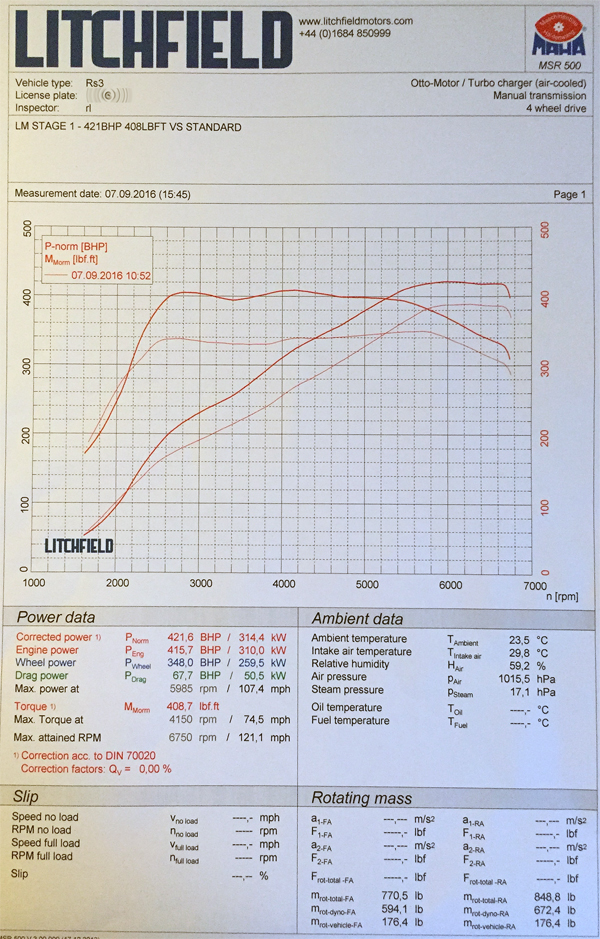

TEST 2 figure achieved was 421.6bhp & 408.7lbft @ flywheel

Comparing this against the stock figure (which is the comparison the graph above shows) we saw the following:

+33.6 bhp +58.7 lbft (peak) over stock

+8.6% bhp +16.7% lbft (peak) over stock

I’ve banged on about this before (probably), but in my experience of using most makes of dynos in the UK over the years, I have always found MAHA dynos to provide quite a stingy torque figure…. Certainly in comparison to other dyno makes. So it’s worth bearing this in mind when you compare figures. Which is seen here with the stock figures as much as the tuned figures in my opinion. But it is what it is.

TEST 2 - Comments

I certainly know I’ve said this before, but one thing that is very important in my opinion, is to not just focus on peak power figures. You really need to look at the whole rev range and thus the whole area UNDER the curve to appreciate improvements.

Considering this was after the initial mapping session, and whilst the peak figures attained are good, there are higher improvements being seen in the mid range.

Looking at the graph you can see that whilst torque is by and large a nice increase throughout the mid range by around +60lbft, the power is seeing increases through the mid range of +50 bhp.

To me, for a road car, it’s about torque and mid range grunt.

TEST 2 - Road

Yeah….. That’s different!

I’ve always thought the stock RS3 was already quick, which is in part down to it’s power delivery and smoothness. This map just amplified the stock delivery, whilst retaining the stock characteristics. This map almost felt too smooth though, however, smooth delivery can mean in reality a quick car!

The car was certainly more urgent in the mid range (increased torque) and felt like it was pulling harder at the top end.

Being honest I suppose I was expecting more. Don’t know why though. Although expectation is normally high when going through a tuning process, but let’s be honest, this map was far from finished. So I needed to put things into perspective.

It felt good and quicker, but just didn’t blow my socks off. But then will Stage 1 ever do that. We’re all greedy aren't we!

The noise……

Initially I didn’t think there was much of a difference on the road, but when you start driving a bit more, you really do notice the bigger growl. Because the RS3 switches the exhaust flaps dependant on throttle, it is more or less as before until you open it up….. Then it really does sounds awesome. Something I have noticed is perhaps a very slight drone now at cruise 70-80mph. It’s only very slight and I can’t say I noticed it before. It’s certainly a great and cheap mod to make in my opinion. These engines sound awesome…. These decat pipes just makes it sound that much more awesome!

It was agreed to carry on with the mapping development in a couple of days time.

TEST 3 - Revised ECU Remap and Secondary Decats

So, the second session of mapping commenced. First off we took a Day 2 baseline run just to ensure that we were still where we left off on the previous session. This run was within a couple of BHP of where we were at the end of Day 1 (as per TEST 2), so we were good to go.

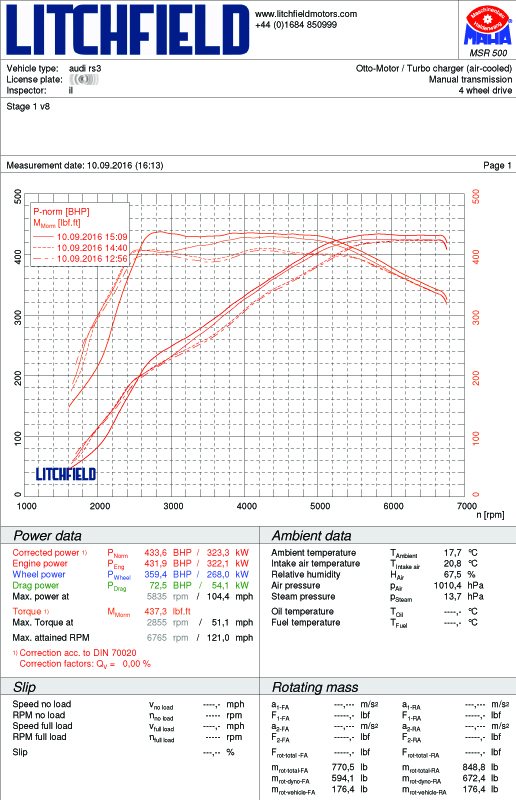

Again, just to go through the process we followed…. On Day 2 we took the map (currently on the car) from the end of Day 1 and called that Stage 1 v1. During this session we went through a similar task as the previous session, carrying on where we left off. During this session we created 9 new maps, although the last revision didn’t make any positive difference so we reverted back to the v8 map from this session. Litchfield’s had already created 6 new maps prior, and we created 3 additional new ones on the day (using what was learnt during this specific session).

We were on the dyno for around 4 hours for this session.

Summary of Spec

MY16 RS3

Litchfield Stage 1 ECU calibration

Miltek Secondary Decat Pipes

Fuel - VPower Nitro (99 oct)

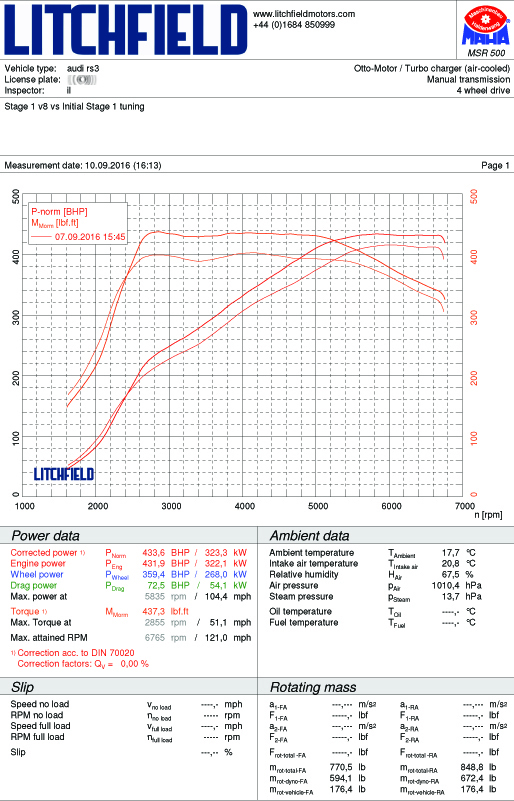

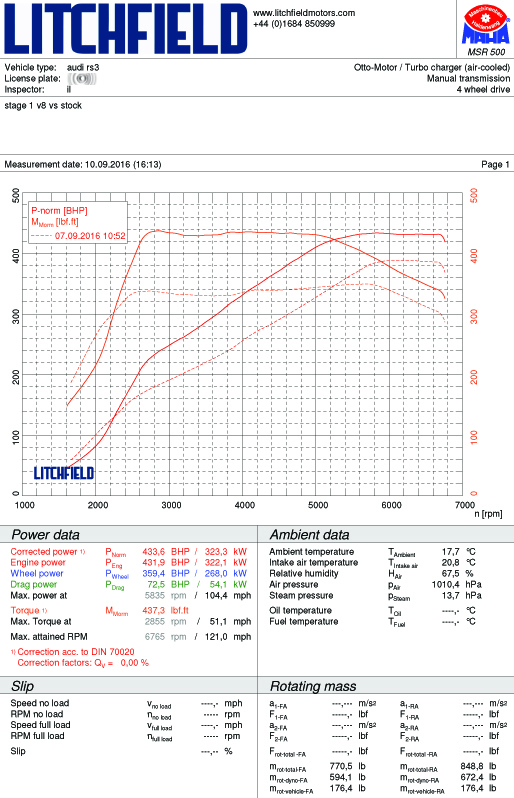

TEST 3 figure achieved was 433.6bhp & 437.3lbft @ flywheel

Comparing this against TEST 2 figure (which is the comparison the graph above shows) we saw the following:

+12.0 bhp +28.6 lbft (peak) over TEST 2

+2.8% bhp +6.9% lbft (peak) over TEST 2

Overall Stage 1 Test 3 comparison against stock

+45.6 bhp +87.3 lbft (peak)

+11.7% bhp +24.9% lbft (peak)

TEST 3 - Comments

Obviously at this stage all I had to go by was the dyno data (and logs), but if you appreciate what a “good” road car dyno graph can look like, this is one of them in my opinion.

Two things to point out initially about the graph. One being the way the car was loaded up for this run. This is highlighted by the initial shape of the torque and power curve up to around 2150rpm. This isn’t a mapping issue which has caused this, this is purely because the car was not loaded on the dyno from a low enough rpm. It’s just the way this one was run (mistake by the dyno operator). It’s only that initial part of the run that was affected.

The second point (and I’m being really nit picking / **** here) is the very very slight dip (it’s probably in the region of 6lbft) in torque from 3-3800rpm. That is also replicated in the power curve for the same rpm. This is due to a very minor but further adjustment being needed to the boost control, as it looks like the ECU thinks it’s going to overboost just as it reaches initial peak boost, so it pulls back the boost slightly and then increases the boost again.

These two minor things to one side, this is such a smooth curve. The torque is virtually flat decked throughout the mid range. The power curve also looks so linear up to peak power, and then manages to hold that peak (virtually) through to the limiter.

If you compare the stock torque curve through the mid range, and even the torque curve result as part of the first mapping session, you will see that there is so much more control now in this area on this version of the map.

Even without getting the car on the road (which we did when we were happy with map, just to double check the logs on the black stuff), the curves alluded to a very nice driveable map.

As before let’s look at what increases have been seen through the mid range…..

In parts we’re talking +100 lbft and on average +90 lbft. With the BHP you’re seeing +80 bhp through a large amount of the same mid range. Those are some significant increases!

Due to time cracking on it was decided to call it a day….. For now.

For further context here is a dyno comparison of just a sample of the maps tested during this recent session. I won’t go into boring detail but you can see differences in the runs which were the outcome of the different maps. This was all part of the testing / learning process to end up with the final result.

TEST 3 - Road

Being honest I really wasn’t expecting much of a change on the road from the previous session map outcome. Perhaps I’d just desensitised myself. Lol

I fully appreciate this will be so subjective, but I thought I would just share the feedback I provided back to Iain after I go home. This is straight up and honest feedback, that was certainly never intended to be made public. But since this is what I felt / feel, I thought I would share.

“It's jeffing awesome mate.

I've never seen the traction control light coming on so much!!!! lol

I was genuinely laughing and smiling on the way home.

It's feels like a totally different car since Wednesday's map, which I wasn't expecting.

Whilst it's still very smooth and the gearbox just sucks everything up you give it, the way the power comes in (urgency and magnitude) on a low rpm pull is fantastic. With the A45 it felt you had to properly wind it up (they are pretty much at the same peak figure level now). With this though, it's much more responsive and instant.

You can feel a big improvement both in the midrange and top end since Wednesday. It feels quite exciting when you keep your foot in, which it didn't on Wednesday. Mid range feels very smooth.... but it feels like it's pulling so hard.

Top end feels like it's giving measurable improvements over Wednesday.

I look forward to your further map tweaks!!!! Get mashing that keyboard!!!!”

To be honest I’m not going to add anything else. I could keep banging on about how it feels etc but there is little point wasting bandwidth! lol

For me that’s Stage 1 done and dusted.

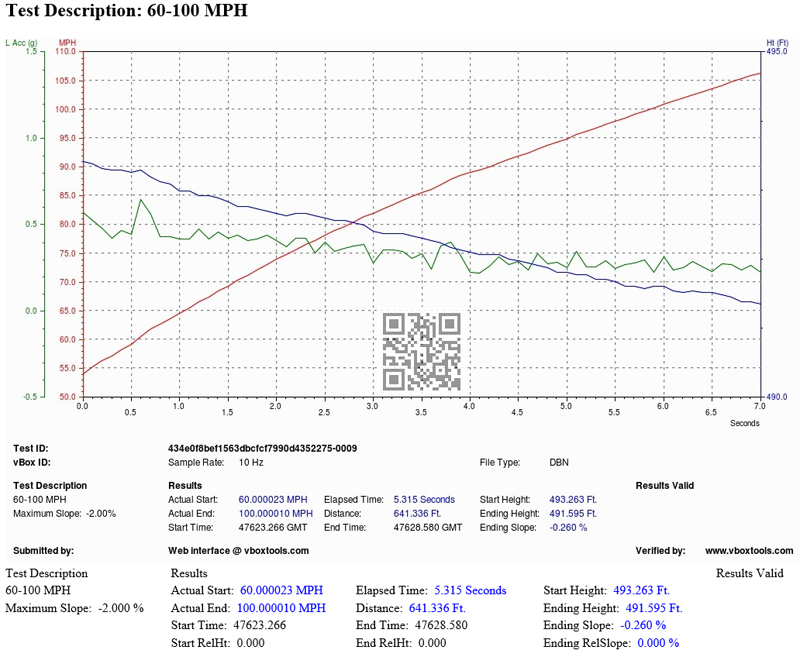

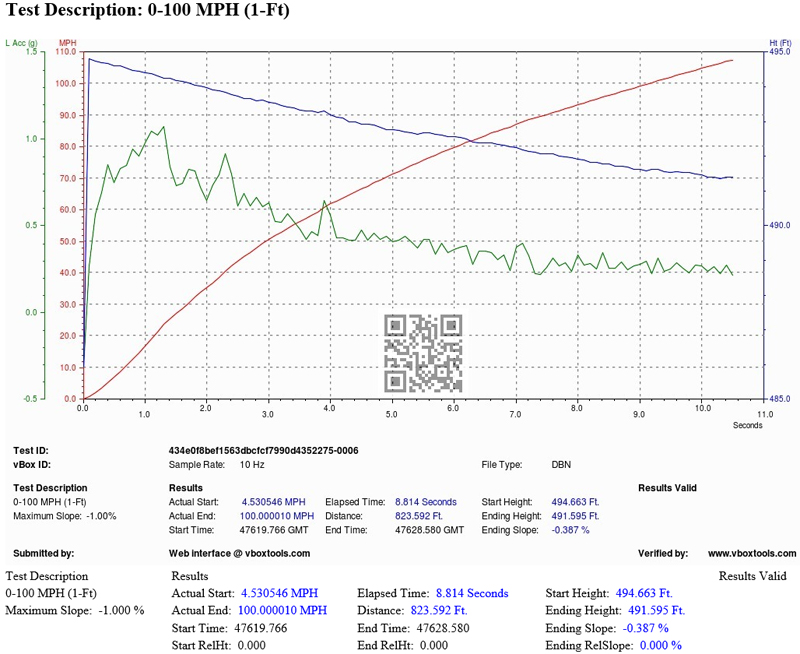

I intend to get down the quarter mile again this weekend and also carry out some VBOX logging. As and when I get these performance measures I’ll update this thread. It will be interesting to see where the car is in relation to my stock performance data.

Stage 2 will begin in a couple of weeks…. So expect more news on that very soon!

TEST 1 - Baseline Figure

Apologies as I’m awaiting the separate stock graph PDF to be sent to me. I’ll update this as soon as I have it. The graph is used on some of the overlays seen further on, so at least we have clear reference points at the moment to discuss.

Summary of Spec

Standard MY16 RS3

Fuel - VPower Nitro (99 oct)

TEST 1 figure achieved was 388bhp & 350lbft @ the flywheel

TEST 1 - Baseline Figure - Comments

Well we already appreciate how quick this car is, even in standard form on the black stuff. But in reality this is due to a number of things. The area under the curve, the gearbox and Haldex system - as a complete package it pretty much rocks, but what does the “pretty” graph tell us about the power delivery.

The area under the curve is always more relevant than the peak figures.

I can normally look at an entire power graph and make a decent judgement as to the potential of the power delivery and flexibility on the road, taking into account the power band and torque available. Make no mistake, it’s the torque that gets you to where you want to go…. Quicker.

Since the MAHA RR is able to appropriately load the engine up, you can deduce how the turbo comes on song. You can see here that you’re achieving near (around 340lbft) peak torque at around 2600rpm, which in 4th gear is pretty good. Suffice to say, due to loading, you will see peak torque coming in slightly earlier the higher the gear. So 5th would see this 2800rpm drop slightly….. this is all normal (3rd gear would be slightly later and so on).

Low rpm’s for torque makes for more pace from lower revs, however by looking at this torque curve you see the RS3 holds this torque pretty well all the way through to 5800rpm. For a road car that is a nice torque band. This is why the mid-range feels really strong on the RS3 and explains why the engine keeps pulling through the rev range. When you combine a wide torque band, with an early onset of torque, you end up with a very agile package.

There are a few peaks and troughs throughout the torque curve, but these don’t really “get in the way” of the power delivery. We’ll come on this later.

When we also see how much more power/torque this turbo can provide further on, it makes the overall set-up even more amazing.

So what else can we find out?

Another advantage of most rolling roads is that you can also capture and overlay other data, that is gathered at the time of the dyno run. This data either comes from plugging the dyno into your OBD port, or buy connecting additional sensors to the dyno, directly connected to the car.

I did capture a lot of data on all runs but it was a mix between additional sensors (true wide band sensor), ODB to dyno and also using VCDS. Which leads me on to the next subject….

VCDS (previously known as VAGCOM)

I won’t bore you guys with talking about what VCDS is…. I’m suspecting most of you guys know, but what I will concentrate on is talking about the logging facilities as this was the real reason why I purchased VCDS.

In basic terms the ECU reads a varied number of sensors (some dependant on OEM ECU version). Upon looking at the sensor readings available via VCDS, you may be overwhelmed by what data sets can be logged.

You may be thinking why I can’t just plug in a simple OBD reader into the car and use a smartphone app etc to read the sensors. The main constraint with this is that these loggers / scanners only read generic OBD codes (PID’s) generally. Some applications will also decipher / read manufacturer specific codes, but not to the extent that VCDS does. VCDS reads all the VAG sensors that I’m aware of, and it’s access to this information that I wanted.

Whilst some may be meaningful, others will have the reaction of "What the hell does that mean?". Obviously to a professional or knowledgeable enthusiast, this will equate to useful data but in reality the majority of us will neither understand or be interested to a degree...... but make no mistake they can all be meaningful.

Here is a screenshot of a log I took (excuse the rather slow sample rate - that’s my fault) for the stock level of tune.

This specific screen shot shows two logs in the same file.

They both contain all sorts of data varying from timing retard per cylinder, boost, charge air temp and ambient temps, fueling, overall ignition, camshaft timing etc. You can view all sorts of useful date which is very very useful (needed) when you’re mapping. All of these are normally recorded against RPM.

There are so many different sensors and you can log up to 12 different sensors at a time in VCDS.

Stock Boost

As we’re talking about the stock tune here, you can use the screenshot above to see how much boost the car makes on a stock tune as seen at the manifold.

If you look at the Engine Speed column on the left (uppermost log) and scan across to the last column (Intake Manifold Pressure), you’ll see what boost was achieved at what RPM. Whilst the sample rate is quite slow (as in the RPM increments), this does give you a good idea of boost attained at the manifold.

You must remember that the boost shown includes 1 atmosphere of measure as these are absolute readings, so you must take 1 atmosphere (1 bar effectively) off to get an appropriate reading. These are also shown in hPa as opposed to PSI or BAR. 1000 hPa is basically 1 bar, so it doesn’t take long to work it all out.

I’ll do the conversion to BAR to make it easier for you to read:

Whilst it doesn’t show it in this log, stock boost peaks at around 1.2bar, but you can see that boost does fluctuate throughout the rev range. This is also shown in the torque curve, which for a standard car isn’t that flat to be honest. On the stock dyno runs of the RS3 you can see the torque (and power) fluctuate through the mid range, and this is largely due to boost fluctuation / control. Boost control could have been tighter to be honest, but it is what it is.

As you may expect, you can see boost tails off towards the redline (just below 1bar).

Charge Temp

Something else you can see on the above log is the Intake Air Temp which is the temperature of the air after the intercooler. This is very important for turbocharged cars and is certainly an area that can cost you power as well as gain you power.

Effectively the cooler the air entering the engine after the turbocharger (and intercooler), the more dense it is and the the bigger bang you can achieve. Figures you attain here can inform you whether you’re over heating the charge air (by running the turbo beyond its efficiency) and/or have an effective intercooler.

It’s also useful to log the ambient temperatures so you can see the delta (difference) between the two temps.

You’ll see here that the charge temp (intake) is fairly OK, but rises as the run moves through the revs and more boost is being applied and everything heats up.

Cooler charge temps are the best (icing issues to one side), but I was always told in the old days that ideally you should aim for charge temps below 40degs. Anything over that will apparently start to impact power more.

Considering this is a dyno cell, and although it has very good airflow, it can’t match the cooling the car would receive on the road, so the figures attained here on the oem setup are OK. Repeated dyno pulls will start to increase temps, but on the runs we did they quickly stabilised again.

Fuelling

Again on the same log above you’ll see fuelling being logged (shown by the column giving a Lambda reading). Ignoring the last row @ 6733 (the throttle was lifted here), the Lambda figure slowly decreases as the revs rise. This means the fuelling starts off lean (more air than fuel) and gradually richens up (more fuel) as the power / boost rises. What you would expect.

It is possible to gain power (and lose it) depending on what fueling strategy you choose. Rich or lean mixtures have their benefits and disbenefits. However, I’m led to believe that with direct injection (as used in the RS3), you have much more flexibility with what you can do with the fuelling.

Ignition

The final element to highlight is the ignition adjustment, which is also on the same log above.

Again, as the rev rise and boost builds the ignition is slowly adjusted, with stock peak ignition adjustment running at around 11degs of advance.

All the above are the basic elements to consider when tuning a turbocharged car. There are a lot more, certainly in this ECU on the RS3, but these are the basics. But you’ll probably appreciate now how important log information can be, especially when you’re looking to start tuning a car.

So with the benchmark data logged and the car pulled off the dyno…. Let’s move on to the first item to change.

Secondary Decats

Quite a common mod on the RS3 so I thought it would be rude not to.

The RS3 has several cats, both in the downpipe and the secondary mid section. It’s the secondary ones I decided to remove as it’s a fairly straight forward and inexpensive mod.

To be honest the OEM exhaust system doesn’t look that restrictive visually, but may need to be looked at further down the line.

You’d have thought that removing a couple of cats would release some power. We’ll find out.

The main reason I chose this mod was for the noise increase though. Whilst the stock car sounds very nice, I wanted to unleash that rumble a touch more. If we saw any increase in power that would be a bonus, but it wasn’t really expected from my perspective.

These are what we’re going to remove:

These are what we’re going to replace them with, a set of Miltek secondary decat pipes:

With both sets side by side:

It’s clearly quite obvious what the difference is between the two sets of pipes!

So with the new decats on, it was time to bang the car on the dyno and see what we could see.