100 PCD hub upgrades - light weight geometry corrected hubs anyone

#1

There has been a thread that has been on 22B for some time looking at options for uprating the front hubs/bearings on a 100PCD car for me hasn't really answered the questions or given a proper solution.

The Hatch WRX hubs are a decent option with a bearing which in terms of strength and durability would appear to lie somewhere between the press in new age bearing type and the bolt in pack of the 114 PCD hubs. It has the obvious drawback of having a different ABS sensor arrangement which would be an issue for ABS equipped cars or anyone thinking of retrofitting ABS.

Going to a 114 PCD hub has the problems associated with the strut mounting points as well as the obvious PCD issue and hub flange size. None of these are show stoppers but would require a fair bit of engineering adjustment.

I have recently looked at a number of options and the only logical option would appear to be a light weight alloy hub in the same vane as the Elise GT type hubs or something like the Brypar hub. The LIC hubs were a good idea but for the cost they didnt seem worth it from a financial perspective.

Obviously cost become a deciding factor with ideas like this but it seems to me that a light weight hub which raises the bearing mounting in the hub, provides adjustable steering arm mounting to give a bump steer adjustment, allowing roll centre adjustment and offset shims for camber adjustment is the way to go.

i have been in touch with a company that has designed and produced this sort of item before and they are interested in looking at the possible production, there obviously needs to be a market for this which in many ways would be determined by cost. If this was an option would it be beneficial to use a Hawk 100 PCD bearing pack which gives a direct 100 PCD option and off the shelf replacement, use a 114 PCD bearing pack re drilled to 100 PCD with the bearing flange turned down to allow fitment to most wheel and brake options or a bespoke dual PCD bearing pack.

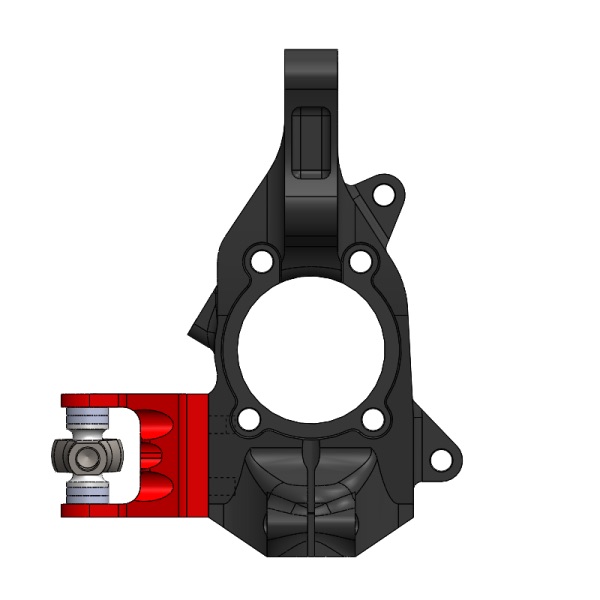

Elise GT hub

Brypar hubs

The Hatch WRX hubs are a decent option with a bearing which in terms of strength and durability would appear to lie somewhere between the press in new age bearing type and the bolt in pack of the 114 PCD hubs. It has the obvious drawback of having a different ABS sensor arrangement which would be an issue for ABS equipped cars or anyone thinking of retrofitting ABS.

Going to a 114 PCD hub has the problems associated with the strut mounting points as well as the obvious PCD issue and hub flange size. None of these are show stoppers but would require a fair bit of engineering adjustment.

I have recently looked at a number of options and the only logical option would appear to be a light weight alloy hub in the same vane as the Elise GT type hubs or something like the Brypar hub. The LIC hubs were a good idea but for the cost they didnt seem worth it from a financial perspective.

Obviously cost become a deciding factor with ideas like this but it seems to me that a light weight hub which raises the bearing mounting in the hub, provides adjustable steering arm mounting to give a bump steer adjustment, allowing roll centre adjustment and offset shims for camber adjustment is the way to go.

i have been in touch with a company that has designed and produced this sort of item before and they are interested in looking at the possible production, there obviously needs to be a market for this which in many ways would be determined by cost. If this was an option would it be beneficial to use a Hawk 100 PCD bearing pack which gives a direct 100 PCD option and off the shelf replacement, use a 114 PCD bearing pack re drilled to 100 PCD with the bearing flange turned down to allow fitment to most wheel and brake options or a bespoke dual PCD bearing pack.

Elise GT hub

Brypar hubs

Last edited by Arch; 12 November 2016 at 11:37 AM.

#3

Not sure at the minute working on costings but a lot depends on choice of bearing pack and work required to that along with final design spec.

One thing Being consideried for example is building in a set amount of camber in the hub so that the adjustment required is less, so say for example build in -1 deg of camber and provide a further amount via offset inserts to limit the need for camber bolts. There isntba need for a lot of camber on the front somewhere around -1.5 to -2 deg is the normal.

One thing Being consideried for example is building in a set amount of camber in the hub so that the adjustment required is less, so say for example build in -1 deg of camber and provide a further amount via offset inserts to limit the need for camber bolts. There isntba need for a lot of camber on the front somewhere around -1.5 to -2 deg is the normal.

#5

the idea is to definately use a bolt in bearing initially with a view to solving some issues with the 100 PCD hub variants but can't see why an alloy hub can't be produced onnthe same vane but with the 114 PCD strut mount.

As things stand for a 100 PCD set up using a modified 114 PCD bolt in bearing a 2.5 Kg per side weight saving is what is achievable over and above the geometry and bearing improvements.

As things stand for a 100 PCD set up using a modified 114 PCD bolt in bearing a 2.5 Kg per side weight saving is what is achievable over and above the geometry and bearing improvements.

#6

the idea is to definately use a bolt in bearing initially with a view to solving some issues with the 100 PCD hub variants but can't see why an alloy hub can't be produced onnthe same vane but with the 114 PCD strut mount.

As things stand for a 100 PCD set up using a modified 114 PCD bolt in bearing a 2.5 Kg per side weight saving is what is achievable over and above the geometry and bearing improvements.

As things stand for a 100 PCD set up using a modified 114 PCD bolt in bearing a 2.5 Kg per side weight saving is what is achievable over and above the geometry and bearing improvements.

Sorry i should have been clearer, i want 5x114 kn classic fitment....

Would these utilise all the existing fixing and bracketry for the calipers etc?

#7

Yes they would be based on a 100 PCD hub but with the upgraded 114 bearing pack re drilled and modified to fit 100 PCD brake discs and wheel fitments. The modification at the bearing bearing pack side would not be needed if someone was running 114 PCD wheels and would reduce the cost a little as the machining would not be needed on the bearing pack. The big advantages appart from the weight saving would be the upgraded bearing and the geometry improvements which are a real must for lowered cars and track cars.

The brake fitment on the 114 PCD hub is identical to previous 100 PCD hubs the difference is in the bearing pack flange which is a bigger diametre and can interfere with some 100 PCD discs and old style bells hence one of the reasons for reducing the diametre of the flange for 100 PCD applications, this obviously has the added benefit of saving some weight on the bearing pack.

The brake fitment on the 114 PCD hub is identical to previous 100 PCD hubs the difference is in the bearing pack flange which is a bigger diametre and can interfere with some 100 PCD discs and old style bells hence one of the reasons for reducing the diametre of the flange for 100 PCD applications, this obviously has the added benefit of saving some weight on the bearing pack.

Last edited by Arch; 01 November 2016 at 06:33 PM.

Trending Topics

#17

Former Sponsor

iTrader: (4)

Joe we can offer modified / lightened factory hubs and they seem extremely cost effective

just for reference we have measured a wide-track upright (no bearing) that has been modified in the usual way we have been offering to the rally guys and it is 4.2kgs - the later Hatch STi version isn't quite as light but still hovers around 4.5kgs (the 114 bearing pack modified to 5x100 weighs approx 2.8kgs with studs)

would be intrigued to see how light a billet option could be retaining the strength and durability it requires?

the modified bearing pack and w/track hub weigh basically the same as a std 6spd hub with the added strength/reliability benefits

just for reference we have measured a wide-track upright (no bearing) that has been modified in the usual way we have been offering to the rally guys and it is 4.2kgs - the later Hatch STi version isn't quite as light but still hovers around 4.5kgs (the 114 bearing pack modified to 5x100 weighs approx 2.8kgs with studs)

would be intrigued to see how light a billet option could be retaining the strength and durability it requires?

the modified bearing pack and w/track hub weigh basically the same as a std 6spd hub with the added strength/reliability benefits

#19

Scooby Regular

iTrader: (4)

Joe we can offer modified / lightened factory hubs and they seem extremely cost effective

just for reference we have measured a wide-track upright (no bearing) that has been modified in the usual way we have been offering to the rally guys and it is 4.2kgs - the later Hatch STi version isn't quite as light but still hovers around 4.5kgs (the 114 bearing pack modified to 5x100 weighs approx 2.8kgs with studs)

would be intrigued to see how light a billet option could be retaining the strength and durability it requires?

the modified bearing pack and w/track hub weigh basically the same as a std 6spd hub with the added strength/reliability benefits

just for reference we have measured a wide-track upright (no bearing) that has been modified in the usual way we have been offering to the rally guys and it is 4.2kgs - the later Hatch STi version isn't quite as light but still hovers around 4.5kgs (the 114 bearing pack modified to 5x100 weighs approx 2.8kgs with studs)

would be intrigued to see how light a billet option could be retaining the strength and durability it requires?

the modified bearing pack and w/track hub weigh basically the same as a std 6spd hub with the added strength/reliability benefits

#20

Guys could we keep this to the discussion about the alloy hub in question it's a totally different solution to a different problem. The idea of these hubs is to improve the geometry of the hub, make it as strong as a 114 hub, utilise a lightened and pcd adjusted 114 bearing pack and keep the wright the same or slightly less than a Hatch WRX hub an bearing pack. For info a standard Hawk 114 PCD hub and bearing pack assembly weighs 8.5kg a Hatch WRX assembly weighs 6kg.

#21

Following on from a discussion over on 22B Price is very dependant on spec, for example it would be a cheaper to produce the hub using a hatch 100 PCD bearing pack but is that what people want etc etc. That was the real purpose if the thread, to gauge what spec people would want to even consider an option depending on price.

There is however a lot of logic in using the 100 PCD Hatch WRX bolt in bearing pack, I have used Hatch WRX hubs and bearing packs on the front of the RA all year and have checked them tonight and there is zero play in the bearing packs, it would be interesting to hear the experiences of others using them on track to see if they are standing up to hard track use mine certainly have. If they are then they are a cost effective solution to use in an alloy hub both from the perspective of initial cost but also the ease of in service replacement i.e bolt straight in without the continued costs associated with the engineering work required to a 114 PCD bearing pack to change the PCD and turn down the flange.

There is also an option to use a dual PCD bolt in bearing pack that has been used on the Elise/Exige but there is no test or experience to say it would stand up to hard track use on a heavier more powerful Impreza.

If you consider the cost of modifying a 114 PCD hub and bearing pack to fit a 100 PCD car its not as cheap an option as it may first appear.

I think you would be lucky to change to a 114 PCD hub for £300 a corner.

2nd hand 114 hub say £80 + new nearing pack £110/120 + cost to change bearing pack pcd + cost to modify strut mount = ?

There is however a lot of logic in using the 100 PCD Hatch WRX bolt in bearing pack, I have used Hatch WRX hubs and bearing packs on the front of the RA all year and have checked them tonight and there is zero play in the bearing packs, it would be interesting to hear the experiences of others using them on track to see if they are standing up to hard track use mine certainly have. If they are then they are a cost effective solution to use in an alloy hub both from the perspective of initial cost but also the ease of in service replacement i.e bolt straight in without the continued costs associated with the engineering work required to a 114 PCD bearing pack to change the PCD and turn down the flange.

There is also an option to use a dual PCD bolt in bearing pack that has been used on the Elise/Exige but there is no test or experience to say it would stand up to hard track use on a heavier more powerful Impreza.

If you consider the cost of modifying a 114 PCD hub and bearing pack to fit a 100 PCD car its not as cheap an option as it may first appear.

I think you would be lucky to change to a 114 PCD hub for £300 a corner.

2nd hand 114 hub say £80 + new nearing pack £110/120 + cost to change bearing pack pcd + cost to modify strut mount = ?

#22

I can now update on the original ideas with a guide price for these. The uprights have been designed and will be produced by Spitfire Engineering Designs Ltd.

http://www.spitfireengineering.com/

The main section of the upright will be made in 7075-T6 which is the highest spec Aluminium alloy available in this size and the steering arm section in 6082.

The steering bearing will have one of Spitfire's proven toe link bearings, this should pretty much be a once only fit and will come with a pre fitted nitrile protective boot.

All steering components and bump shims are 316 stainless apart from the HT bearing itself.

All aluminium components are hard anodised in the Spitfire shade (titanium) or in other colours as preferred though we always suggest hard anodising.

The design will incorporate adjustability for:-

Bump steer

Steering ratio

Camber (set into the upright and/or strut pickup points allowing the strut top mount to re-centre for additional range) TBD

Castor (this will be designed in allowing the strut top mount to re-centre for additional range) TBD

The uprights will be pre assembled ready to fit.

Due to the materials and finish you can expect the uprights to last the life of the car.

New, machined lightened bearing packs can be supplied with a range of PCD options and can incorporate low heat transition patterns if wanted.

Pricing is based on 10 sets for the initial order and includes a £100 pre-order discount

Complete set up including upright pair C/W steering components and PCD adjusted bearing pack £1695*

New, machined flange bearing packs sold separately if required are £160+ each depending upon requirements.

All prices are plus VAT and delivery.

Due to the high material costs we would look for a deposit of 35% which would not be refundable if cancelled.

If the order is higher we can look at revised pricing.

All products are for track use only.**

Due to their anticipated usage no warranty is supplied or implied**

* this needs to finalised depending upon specification but it is unlikely to rise.

** A legal requirement

http://www.spitfireengineering.com/

The main section of the upright will be made in 7075-T6 which is the highest spec Aluminium alloy available in this size and the steering arm section in 6082.

The steering bearing will have one of Spitfire's proven toe link bearings, this should pretty much be a once only fit and will come with a pre fitted nitrile protective boot.

All steering components and bump shims are 316 stainless apart from the HT bearing itself.

All aluminium components are hard anodised in the Spitfire shade (titanium) or in other colours as preferred though we always suggest hard anodising.

The design will incorporate adjustability for:-

Bump steer

Steering ratio

Camber (set into the upright and/or strut pickup points allowing the strut top mount to re-centre for additional range) TBD

Castor (this will be designed in allowing the strut top mount to re-centre for additional range) TBD

The uprights will be pre assembled ready to fit.

Due to the materials and finish you can expect the uprights to last the life of the car.

New, machined lightened bearing packs can be supplied with a range of PCD options and can incorporate low heat transition patterns if wanted.

Pricing is based on 10 sets for the initial order and includes a £100 pre-order discount

Complete set up including upright pair C/W steering components and PCD adjusted bearing pack £1695*

New, machined flange bearing packs sold separately if required are £160+ each depending upon requirements.

All prices are plus VAT and delivery.

Due to the high material costs we would look for a deposit of 35% which would not be refundable if cancelled.

If the order is higher we can look at revised pricing.

All products are for track use only.**

Due to their anticipated usage no warranty is supplied or implied**

* this needs to finalised depending upon specification but it is unlikely to rise.

** A legal requirement

#23

Scooby Regular

iTrader: (2)

Join Date: Mar 2012

Location: somerset

Posts: 598

Likes: 0

Received 0 Likes

on

0 Posts

Sounding good

Any pics of the design with a few dimensions showing the amount of adjustment for steering ratio, bump steer etc?

What camber angle with the strut top centered? Does this use a cylindrical bolt in place of the cam shape upper camber bolts?

I assume castor will be fixed at a given angle?

Any pics of the design with a few dimensions showing the amount of adjustment for steering ratio, bump steer etc?

What camber angle with the strut top centered? Does this use a cylindrical bolt in place of the cam shape upper camber bolts?

I assume castor will be fixed at a given angle?

#24

Tom the idea Is to build in a fixed amount of camber say -1.5 deg or more then adjust the rest via offset shims on the top strut holes. Most people run around -2.5 ish so what would be ideal is to not have to use any camber bolts and have most of the final adjustment via offset bushes in the strut hole. Same with Castor build in as much as possible. It will also have the bearing moved up by somewhere between 25 - 33mm when compared to OE spec. The figure we had looked at in terms of increase in rack ratio was 10% will need to ask the question how difficult it would be to increase this.

The idea at the minute is to have these 100PCD at the strut Will need to check if there is a demand for 114 at the strut can't see it being too much of a problem in terms of design.

The bearing packs are going to be a 114 PCD Bearing pack modified to 100 PCD so that would be no problem is someone wanted to change to 114 PCD wheels it's only a bearing pack change.

It hasn't been CAD drawn fully but the guys at Spitfire know the design they plan which won't be far removed from the current hub design or the Brypar one but with more geometry changes. Once it's known if the numbers are there it will be CAD drawn and a full stress analysis done on the design before production. There has been a lot of work gone in to get to even this stage but it needs enough numbers of people who see the benefits available and willing to pay this for them before it will go to the final stage.

The idea at the minute is to have these 100PCD at the strut Will need to check if there is a demand for 114 at the strut can't see it being too much of a problem in terms of design.

The bearing packs are going to be a 114 PCD Bearing pack modified to 100 PCD so that would be no problem is someone wanted to change to 114 PCD wheels it's only a bearing pack change.

It hasn't been CAD drawn fully but the guys at Spitfire know the design they plan which won't be far removed from the current hub design or the Brypar one but with more geometry changes. Once it's known if the numbers are there it will be CAD drawn and a full stress analysis done on the design before production. There has been a lot of work gone in to get to even this stage but it needs enough numbers of people who see the benefits available and willing to pay this for them before it will go to the final stage.

Last edited by Arch; 12 November 2016 at 05:21 PM.

#25

Just so as it is clear I have no financial interest in this for me it is to see if it is viable for a someone to produce a hub like this in the UK and if there is a market for this. It is clear there is a market for it whether there is a market at the price it takes to produce is now the question.

#26

Just so as it is clear I have no financial interest in this for me it is to see if it is viable for a someone to produce a hub like this in the UK and if there is a market for this. It is clear there is a market for it whether there is a market at the price it takes to produce is now the question.

"I'm out..."

I think for these to be worth while they would need to be sub 1k for me. The overall benefit of the corrections etc, it small unless looking for every 10th of a second, and in reality, I am not at that point yet, There are other gains I can make which are probably more cost effective...

I really appreciate the effort you have gone to for this, credit is due for trying to bring something new to the game and its nice to see some innovation!

#27

As they say on the "Den"

"I'm out..."

I think for these to be worth while they would need to be sub 1k for me. The overall benefit of the corrections etc, it small unless looking for every 10th of a second, and in reality, I am not at that point yet, There are other gains I can make which are probably more cost effective...

I really appreciate the effort you have gone to for this, credit is due for trying to bring something new to the game and its nice to see some innovation!

"I'm out..."

I think for these to be worth while they would need to be sub 1k for me. The overall benefit of the corrections etc, it small unless looking for every 10th of a second, and in reality, I am not at that point yet, There are other gains I can make which are probably more cost effective...

I really appreciate the effort you have gone to for this, credit is due for trying to bring something new to the game and its nice to see some innovation!

Its a fair point they are not cheap and as I said previously people need to do the cost v gain analysis, there are significant gains to be had from these but everyone has to decide if they are right for them.

There are a lot of ways too look at it but ultimately it comes down to budget.

If someone wanted to just uprate the bearings by moving to a 114 PCD hub there would be an estimated cost of £550 to £600 for the pair. I arrive at that by the following calculation: two second hand hubs £160 + two new bearing packs £240 (would be madness to use the old bearing packs), machine work to convert bearing packs to 100 PCD and strut fitment to 100 PCD strut got to be easily £150 - £200 so somewhere close to £600 and all you have done is uprate the bearing pack and added weight.

To throw a spanner in the works if you are running ABS and a non widetrack drive shaft you will have issues aligning the ABS sensor with the ABS ring on a 114 hub so you may well need to engineer that out or possibly move to a widetrack driveshaft which creates issues at the gearbox end as the widetrack shaft is male fitment and will also widen your track and change your geometry.

If the alloy hub has a steering ratio change of 10% ( more may be possible) then a 2.75 lock to lock rack becomes 2.475 lock to lock so you have just saved yourself £300 on a quick rack.

There are other parts that may be fitted to correct for the car being lowered which again would not be needed but they will not fully correct for the sort of drops seen on a track car so if you actually add it up yes the alloy hubs are more expensive but the benefits then become cheaper when compared to the total cost from conventional routes. The headline figure seems expensive but once you sit down with a bit of paper and add up parts on a track car you may be surprised.

#28

Happy to take comments positive and negative a healthy debate will get to the point quickly i.e are there viable numbers or not.

Would add that the Brypar hubs are a fair bit more expensive and don't do as much, and that's before shipping and taxes, the LIC hubs were also more expensive but as mentioned many were uneasy about welding to a cast structure and they also did not do anything like the proposed hubs in terms of geometry changes..

Would add that the Brypar hubs are a fair bit more expensive and don't do as much, and that's before shipping and taxes, the LIC hubs were also more expensive but as mentioned many were uneasy about welding to a cast structure and they also did not do anything like the proposed hubs in terms of geometry changes..

Last edited by Arch; 13 November 2016 at 05:13 PM.

#29

To be honest Arch, they are going to be very good.

Could there be an option for something with slightly less adjustment at a more reasonable price?

I have a set of classic converted 5x114 hubs already, i appreciate they are heavy so I could be interested in something better. However I am as you already say 600£ in for these...

Could there be an option for something with slightly less adjustment at a more reasonable price?

I have a set of classic converted 5x114 hubs already, i appreciate they are heavy so I could be interested in something better. However I am as you already say 600£ in for these...

#30

Subaru Tuning Specialist

Join Date: Jun 2002

Location: 7.74 @179 mph 1/4 mile - road legal

Posts: 6,654

Likes: 0

Received 1 Like

on

1 Post

Archie, how are you compensating for the changes to ackerman when you shorten the steering arm length? (to quicken the rack) and will you be supplying rack stops to prevent over rotation of the struts, which would stress the U/J's etc.